Leading competence

Thanks to innovation and technologies, Cimprogetti is working on progressive outreach for a long-term strategy in the lime industries. At a time when it is essential to introduce adequate skills to be able to predict changes and avoid chasing them in the future, “riding the turnaround” might offer extraordinary growth opportunities for Cimprogetti’s customers.

Introduction

Calcium oxide, commonly known as quicklime or burnt lime, was probably discovered by chance. Ancient civilizations such as the Egyptians, Greeks and Romans crudely burned lime to take advantage of its various properties and possible applications.

The recognized name given to this burned product was quicklime, which is fitting, since the substance decays rapidly after limestone heating, reacting with humidity if exposed to air.

Quicklime is an ancient material, which has marked the fundamental stages of thousands of years of history in construction and architecture. Soft lime burning...

Introduction

Calcium oxide, commonly known as quicklime or burnt lime, was probably discovered by chance. Ancient civilizations such as the Egyptians, Greeks and Romans crudely burned lime to take advantage of its various properties and possible applications.

The recognized name given to this burned product was quicklime, which is fitting, since the substance decays rapidly after limestone heating, reacting with humidity if exposed to air.

Quicklime is an ancient material, which has marked the fundamental stages of thousands of years of history in construction and architecture. Soft lime burning was generally performed in traditional pits, characterized by a process lasting several days and without any control of the firing temperature. It generally allowed a highly porous calcine to be obtained, which, however, is not comparable with “modern” quicklime in terms of production volumes and reproducible quality.

Moreover, besides chemical purity, the quicklime reactivity was not considered a significant criterion to evaluate lime quality until almost after World War Two.

The development of the modern steel production process, in particular the invention of the basic oxygen furnace converter in the early 1960s, heralded a revolution in the lime industry, which steadily became more competitive and able to satisfy the increasing demand for high-grade reactive lime in the latter part of the twentieth century.

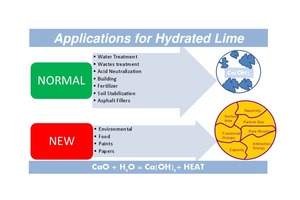

Today, the global production of quicklime stands at more than 330 million t, of which an estimated 25 % is slaked with water to make hydrated lime, in the form of a slurry or as a dry powder that is suitable for the design of mortars as well as innovative chemical products in a variety of different industrial processes.

Over the last few decades, the increasing use of hydrated lime treatments for polluting acid fumes has represented a significant market segment, which is expected to grow significantly in developing countries.

Because of the above reasons, the lime industry is currently undergoing dramatic changes. Significant investments are being made in modern kiln technology and fully automated hydration plants, which are improving the quality of final products, reducing costs and the impact on the environment.

Cimprogetti is one of the leaders in the field thanks to its competence in implementing innovation as well as discovering and following new paths, its commitment in the adoption of the best practices and its gathering of all the available knowledge and technology to ensure success. Cimprogetti stands on five major pillars:

Focus on limestone quality control, especially in terms of burnability properties, based on experimental research that is conducted at the company’s own high-tech laboratory

Optimization of existing equipment through a reduction in downtime with the use of leading IOT applications

Minimization of pollutants in the Parallel Regenerative Kiln with a cutting-edge integrated system

Characterization of different types of calcium hydroxide for a variety of applications in widely diverse sectors

Design of modular solutions, to reduce plant footprint and minimize construction time

1 Focus on limestone quality

Scientific research activity and technological experimentation on carbonate raw materials, mainly limestones and dolomites, and derived burnt products represents, in the Cimprogetti vision, the starting point for any further engineering activity. This strict approach represents the essential base to develop efficient and sustainable technical solutions. Cimprogetti offers its clients worldwide the possibility to submit carbonate rock samples to the Cimprogetti laboratory in order to evaluate the suitability of the materials for the production of quicklime in the industrial kilns supplied by the company. Cimprogetti has so far analysed and stored more than 3000 samples from all over the world.

Geological and mining expertise has led Cimprogetti’s laboratory to become a unique and undisputed knowledge platform, giving its support to major lime producers as well as to new customers, with a complete rock evaluation. This represents a significant plus point in planning the design of new tailor-made kilns and hydration plants.

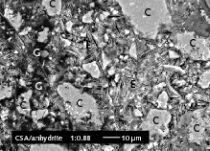

Cimprogetti has developed specific procedures for the characterization of raw materials, burnt and hydrated lime products, mainly by means of X-rays (XRD and XRF), microscopy (optical, SEM) and thermal analyses (TG-DTA) to evaluate the impact of the composition and microstructure of different carbonate rocks on their burnability. Cimprogetti’s innovative and strict approach includes the preliminary lithological classification of as-received samples, followed by mineralogical-petrographic analyses. Furthermore, burnability tests are performed at the Cimprogetti laboratory on massive samples in a thermogravimetric muffle furnace, which allows the extrapolation of kinetic parameters, such as the activation energy and the pre-exponential or frequency factor of the Arrhenius equation. Calcination kinetics represents the key factor for predicting quicklime reactivity.

New test methods are generally validated by means of submissions to scientific peer-reviewed journals, and subsequently disclosed in sector and technical magazines. Moreover, practical experience amassed in the laboratory has been recently shifted to a hydration pilot plant with a capacity of approx. 100 kg/h. The goal was the production of hydrated lime powder with high and very high BET specific surface area.

2 Optimization of existing equipment

An important challenge that Cimprogetti is focussing on is related to the optimization of existing plants and equipment, in order to enhance their characteristics and to enable a prompt response to new requirements owing to technological and environmental innovations.

Thanks to existing technologies, in particular Data Scientists, Cimprogetti has developed a new platform called BOT which is basically a computer program that works automatically to search and retrieve information on the internet, delivering unprecedented value to clients and guaranteeing data security against unauthorized access or attack.

In addition, the development of a new data acquisition system (SCADA) or process control system has greatly improved the management of plants, as well as the interconnection with the information system of the client such as Enterprise Resource Planning (ERP) and innovative Manufacturing Enterprise Solutions (MES). The clients can obtain analytical insights from wherever they are with the introduction of an advanced dashboard, which displays in real time historical data, leveraging data infrastructure based on the use of operational intelligence.

The new platform is fully customizable with different tools, in full accordance with client requirements.

For instance, the TDM module (Trends and Data Management) manages the various production set-ups that are required, automatically calculating the process parameters to be pre-arranged in accordance with the desired quality. Utilizing data and chemical characteristics of raw material and fuel, it automatically adjusts the combustion process, which is typically the leading factor in reducing costs.

It is not surprising that full automation in receiving multiple information, processing and analysing data at various point of the process, greatly reduces the human interface.

Smartphones and tablets have set a great milestone for access to data: with an iPhone or Android mobile phone, it is now possible to manage and interact with the kiln operation and supervision system. Thanks to the enormously increased use of smartphones, access to data has become immensely easier.

Moreover, cloud computing has introduced better synchronization and exchange of documents across different devices.

Interaction in real time and a secure platform to support clients in troubleshooting saves time, guarantees security and enhances the sharing of information.

3 Minimization of pollutants (TurNOx)

Despite the fact that Mr John Fitzgerald Kennedy was not exactly referring to environmental pollution when he made this speech, these words are still really topical and apt for all the environmental matters related to every type of production process. One of the most important challenges of our time is linked to environment preservation and the maximum reduction of every type of pollution.

Cimprogetti’s philosophy is strongly oriented to facing this challenge. The company is always researching and developing new green and sustainable processes and equipment to make it possible to reach this target.

Pollution in Cimprogetti plants mainly concerns the kiln flue gas produced as a result of the chemical reaction that takes place to produce the quicklime during combustion inside the kiln and subsequently emitted into the atmosphere.

The nature and concentration of the emissions are influenced by several factors in the production process. These are, in order of importance:

The chemical composition of the limestone, especially the amounts of organic compounds and the amount or nature of sulphurous components:

The characteristics, especially the chemical composition, of the fuel

The efficiency and the accuracy of the fuel dosing equipment

The excess air for combustion

The “burn out” time for the lances

The operation of the bag filter

The condition of the refractory lining

Amongst all the pollutants mentioned above, NOx emission regulations are becoming increasingly stringent in Europe in particular and worldwide.

For instance, in Europe NOx emission limits have been reduced from 800 mg/Nm3 to as low as 200 mg/Nm3 depending on the type of lime kiln in use under directive 2010/75/EU dated 26 March 2013.

The impact of NOx is higher when fuels with organically bound nitrogen such as coal and oil are used; far less when gaseous fuel such as natural gas is used.

Cimprogetti is testing DENOx catalytic filter bags for post-combustion control of gaseous pollutants such as dioxin, furan and NOx.

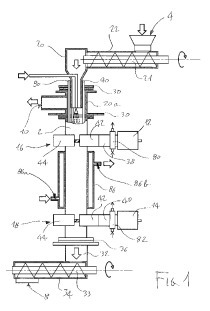

A pilot plant comprising the following units was installed at the slipstream from the exhaust line of the kiln:

An electric heater with temperature control at the inlet of the bag house for conducting tests at various flue gas temperatures

A gaseous ammonia injection unit

A standard pulse jet filter bag house equipped with 24 catalytic filer bags from W.L. Gore and Associates designed to treat off-gases for NOx emission in high dust environments

Continuous emission monitoring systems (CEMS) to monitor critical process parameters of the flue gas and to provide information for combustion control and ammonia slip

The entire NOx reduction process is monitored by a new tool in the HMI system purposely developed by Cimprogetti for the lime industry: the Cimprogetti BOT Platform™.

The emission tool, in particular, strictly controls the ammonia feed rate, maintaining the ammonia slip within a fixed range, which also provides feedback on the catalyst efficiency and lifetime.

In addition, this tool records the flue gas temperature, NOx concentration, air flow rate, while predicting the ammonia quantity to be fed to reach the desired value of NOx at the stack.

4 Characterization of different calcium hydroxides

Cimprogetti doesn’t only mean quicklime kilns; Cimprogetti is also involved in designing and manufacturing production plants for calcium hydroxide, commonly known as hydrated lime.

Calcium hydroxide is a powdery product obtained by mixing calcium oxide with water according to the following chemical reaction; it is used for many different purposes in a range of applications such as the chemical and food industry, agriculture and construction. The most important application, however, is in water purification, acid neutralization and flue gas desulphurization treatments.

CaO + H2O → Ca(OH)2 + heat⇥(1)

The slaking process, which occurs at an average temperature of 100°C, is achieved by adding an adequate stoichiometric quantity of water to moderate the temperature.

The water migrates into the pores of the lime particles, thus hydration occurs in conjunction with material expansion. This causes the splitting of particles, exposing the wet surface, into which more water can migrate.

In the next few years the industrial production of hydrated lime will need either a high-grade conversion process (from oxide to hydrate), or high-surface-area products. Therefore, it will no longer be enough to use a simple mixing apparatus. It will be necessary to examine the hydration kinetics in depth to understand and classify lime behaviour in order to predict the required characteristics of the hydroxide product.

Thus, preliminary modelling and specific laboratory tests will need to be carefully evaluated in compliance with standards and market requirements.

All the following factors have to be considered to design the final product characteristics and to set all the production procedures following the preliminary raw material characterization already described:

water-to-lime ratio

water composition and temperature

water feed timing

retention time inside the hydrator

inside volume of the machine

management of the steam formation

particle size of the raw material

final moisture of the product

The calculation of the adequate quantity of water to be added is particularly important and must take into consideration that not all the water provided to the hydrator will take part in the chemical reaction that finally produces calcium hydroxide. A large part of it will act as a cooling medium, taking up a massive quantity of the heat produced in the chemical reaction by turning it into steam, which is then dispersed into the atmosphere after passing through the bag filter.

The water should be added to the lime under controlled agitation to avoid overheating and agglomeration.

In the near future, Cimprogetti will be launching a fully automated industrial hydrator named Hydrax-Booster BET (patent pending); developed by its R&D Department. It is based on a unique process able to produce high-surface-area calcium hydroxide.

Cimprogetti is one of the world leaders in the hydration process for operational industrial plants. Over 50 years of activity in the field have allowed the company to build up valuable experience in modelling the chemical reaction.

This is especially true regarding the complete conversion of calcium oxide (CaO) into calcium hydroxide (Ca(OH)2), by means of a satisfactory mix-design of different variables involved in the process and the target quality of the product.

5 Design of modular solutions

The plant engineering market is moving fast to smart and flexible solutions in every field of application, with the purpose of saving time and money.

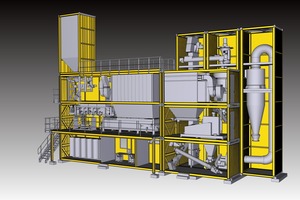

With the aim of responding to this market demand, Cimprogetti has worked out a new modular concept, which has led to the development of a complete modular plant: the CIM-Hydrax-Compact.

The CIM-Hydrax-Compact is a complete and autonomous hydration plant of 10 t/h nominal capacity, based on a compact conventional process (CaO hydration, separation and grinding).

Thanks to the modular design, the compact configuration allows the installation of the hydration plant directly in the production facility with a minimal footprint. The plant can be easily adapted and modified to meet operational requirements.

The CIM-Hydrax-Compact™ is a truly cost-effective/short-lead-time solution. The complete plant is composed of twelve containers (8 of 40’ and 4 of 20’). Some of the components that connect different sections of the system (e.g. screw conveyors, de-dusting pipes) are shipped with two additional carrier-owned containers (COC).

The equipment and structures are already pre-assembled and ready to be installed: assembly is limited to a bare minimum. The containers are an integral part of the hydration plant, acting as enclosing buildings for the equipment.

The plant is designed to be divided into two separate sections:

Hydration section

This section is composed of the quicklime buffer hopper, the quicklime dosing and weighing system, the hydrator with its de-dusting bag filter and the room with the main electric panels

Separation/grinding section

This section is composed of the separation circuit (high-efficiency separator CIM-Microsep™, cyclone and fan), working in closed circuit with a pin mill, the bucket elevator which feeds the circuit and recirculates the milled material, and a de-dusting bag filter.

The module battery limit is the discharging rotary valve under the cyclone.

From this point, the hydrated lime can be sent to the storage silo by means of a mechanical or a pneumatic conveying system.

Conclusion

In mature markets, lime is not expected to grow in terms of volume, but in terms of quality and with regard to protection of the environment. In developing countries such as those in Asia, the Middle East and Africa, it will be possible to record an increase in lime consumption over the next few years.

Challenges facing lime producers in the future will be focussed on:

Technology for generating negative emission of CO2 emissions, as in similar sectors with the emerging technologies of carbon capture or usage

Implementation of a circular economy with the aim of developing processes and resources to minimize waste and energy.

In this context, today it is no longer enough to optimize existing equipment and outdated technologies: companies need solutions to correlate the multitude of data from different fields, including geology, mineralogy, crystal chemistry, physics, mathematics, mechanics, and valuable experience and insights in a unique environment, where this data is shared among different experts.

Thanks to the technologies and skills necessary to face this transformation, Cimprogetti is working on the progressive outreach of an organizational culture that can lead people towards innovations and their advantages.

At a time when it is essential to introduce adequate skills to be able to predict changes and avoid chasing them in the future, “riding the turnaround” might offer extraordinary growth opportunities.

//www.cimprogetti.com" target="_blank" >www.cimprogetti.com:www.cimprogetti.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.