In the building material production and processing industry, various powdery products for a variety of purposes are packed into flexible packaging, in small to large quantities. Depending on the needs and requirements of the end consumer, filling and storing of the filled packages is done using various types of packaging materials. The most frequent and versatile packaging for powder products is the valve sack made of paper.

1 Introduction

Over the recent years, filling systems have been continuously developed to keep up with the ever growing demands for filling performance, weight accuracy and cleanliness. Haver & Boecker has been setting new standards and developing new technologies. The filling of powder materials is a rapidly developing field within process and product automation. Growing demands for performance have changed the view of filling. Modern filling systems today optimally match the requirements on the sack paper, as well as the products that are to be filled with possibilities to adapt the filling machine. The interaction between the product, machine and sack is today generally well-known and scientifically investigated in studies and trials (Fig. 1).

In particular, the Swedish paper manufacturer BillerudKorsnäs has set new standards by developing the high-porosity sack paper product series named QuickFill®. The QuickFill® product series contains both white and brown kraft papers for valve sacks which have been developed for today‘s high-speed converting and filling machines. The wide product range offers a perfect combination of high strength and excellent deaeration properties, meaning that QuickFill® sacks can be optimized in size and sack weight while performing better in filling and handling. The overall filling performance is measured regarding the speed and cleanliness of the packing line.

Haver & Boecker and BillerudKorsnäs both operate research & development centers, where the above described interactions between product and sack are studied with respect to packaging development and customer needs. Together the specialists of both companies have carried out a scientific study focusing in detail on the impact of paper porosity on filling speed. The procedure, trials and results are described in the following.

2 Study description

This chapter describes how the study was conducted in terms of products tested, sack types used and how packaging performance has been measured.

2.1 Tested products

The trials were conducted with two types of cement with different filling behaviours (Table 1):

standard cement and

fine cement

In addition to the characteristics mentioned above there are other important product characteristics influencing the filling behaviour such as; moisture content, flowability, deaeration, powder composition and compaction behaviour.

For the purpose of conducting analysis and trials at its own Research & Development Center, Haver & Boecker developed a series of laboratory equipment that measures process-relevant product properties. Using the measured results, the most economical packaging solution for the customer is determined. BillerudKorsnäs have also the possibility to measure key properties for packaging performance in their own Sack Lab which was a good combination for the study.

2.2 Sack types

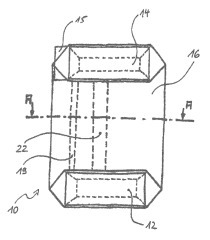

To reduce the amount of parameters, the sack size and design was the same for both cement types. For the entire trial 1200 sacks were prepared in three different porosity levels, for each porosity level 200 sacks were used (Fig. 2). The sack permeability is one of the most important factors influencing the performance of a packing machine. The faster a sack deaerates the air during the filling process, the more efficient the packing machine’s filling performance becomes.

2.3 Measuring packaging performance

For a modern sack solution a number of key properties are important; strength, deaeration, filling, barrier properties, printing and appearance all needs to match in order to have a smart packaging solution. This study is concentrated on the filling performance and therefore the tests concerning deaeration and filling performance are described in detail below.

2.3.1 Gurley

Gurley is the most common test to describe the paper porosity. The gurley equipment measures the time in seconds for 100 ml of air to pass a specific surface of the paper at a certain pressure difference and is applied on single ply paper sheets (Fig. 3).

2.3.2 Haver Big Gurley®

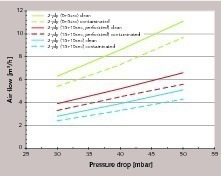

With the Haver Big Gurley® (Fig. 4), the air permeability of packaging material can be measured and assessed. The test equipment provides information about the porosity and air permeability of the sack wall, not only with clean/unused paper, but also with contaminated paper. It shows the influence of the product on the paper during filling (Fig. 5). The fine product particles can decrease the permeability by blocking the holes between the fibers. It is dependent on many factors such as particle size, moisture content, temperature, and so on. With this instrument it is possible to test the complete sack wall construction.

The results show the significant influence of the permeability of clean and contaminated paper (with product after filling). During these trials the permeability decrease is 10 to 15 %. Depending on the product and the paper type the permeability can drop down up to 90 %. This is based on the experience gained in many different studies and customer related tests.

2.3.3 Haver Airflow Tester®

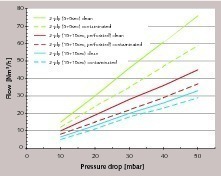

With the Haver Airflow Tester® (Fig. 6), the air permeability of the entire bag, including all paper and plastic layers and glued areas, can be determined. The data contains important information about the filling behaviour. By involving all bag components, especially the glued areas, a total assessment is possible. Worldwide it is today a common standard to describe the sack permeability with this equipment.

The amount of permeability directly influences the filling performance, the cleanliness and the weight accuracy. Many years of experience in filling operations have led to recommendations about the permeability levels needed for different types of filling goods (Fig. 7).

2.3.4 Filling trials

The filling trials with cement are made with a vertical impeller packer (Fig. 8) which is the most common and effective technology for filling powdery goods such as cement. The filling of other products which have the tendency to agglomerate and plasticise, for example E-PVC, has to be done with an air packer (Fig. 9). In general all kinds of products can be filled with the air packer. Because of the fluidisation during filling the amount of air is much higher during filling with air packers and this generates a higher need for sack permeability.

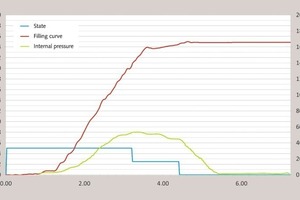

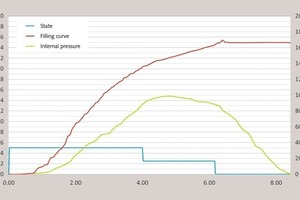

For the purpose of comparing results, the following values were recorded for all trials:

Filling time (blue curve; shows coarse and fine feed)

Sack weight (red curve is the mass flow in kg/s)

Pressure inside the sack (green curve)

As a standard rule it is given that a higher permeability of the empty sack will achieve a better filling performance. Different sack constructions like the 5+5 Gurley seconds made from QuickFill® paper in comparison with the 15+15 Gurley seconds will result in a 20 % quicker filling time and 50 % lower internal pressure inside sack as in this example (Figs. 10 and 11).

3 Comparison of results

Table 2 shows that the difference in the empty sack permeability influences the filling time. The increased pressure inside the sack during filling illustrates the fact that low permeability paper will increase the risk of sack breakages. Perforation is still a common way to have a sufficient venting of the bag, however the product coming out of the holes has a negative effect on the wear and tear of the mechanical equipment, the environment, working conditions, shelf life and packaging appearance.

4 Summary

By evaluating the trials, the results of the study show that it is possible to optimise the filling process so that an improvement in filling time and cleanliness is achieved. The paper properties and the sack design have a considerable impact on filling speed and overall performance. Selecting the right paper quality and the number of paper layers, barrier techniques, or other sack design parameters requires knowledge, and the possibility for analysis to clearly quantify the relationships, and using this knowledge for optimising the filling system.