How is lime production impacted

by digitalization?

Digitalization has become a buzzword in the industry. The permanent availability of abundant data on virtually any device is part of our daily life. But what is it good for? What benefits can be drawn from all these data? The article describes the importance that Maerz Ofenbau attaches to digitalization.

1 Introduction

The heart of a lime plant is and always will be the kiln. Its design and its smooth operation lay the foundation for success. All measures taken by the lime kiln operator, including the decision to have a data collection system, must therefore be evaluated by answering the following three simple questions:

Does the envisaged measure improve productivity?

Does the measure improve quality?

Is a measure beneficial to production costs?

Simply said: Do we come closer to best practice when installing system x or y?

Data collection systems today most often emphasize maintenance only. They...

1 Introduction

The heart of a lime plant is and always will be the kiln. Its design and its smooth operation lay the foundation for success. All measures taken by the lime kiln operator, including the decision to have a data collection system, must therefore be evaluated by answering the following three simple questions:

Does the envisaged measure improve productivity?

Does the measure improve quality?

Is a measure beneficial to production costs?

Simply said: Do we come closer to best practice when installing system x or y?

Data collection systems today most often emphasize maintenance only. They rarely include data which is not available online. This is, however, absolutely mandatory in order to gain the full picture and make the right decisions.

2 A simple case: benchmarking

refractory consumption

Refractory repairs are one of the largest regularly occurring expenses during a lime kiln’s lifetime. The performance of the refractory lining therefore has a significant impact on the overall production costs.

Data monitoring in these cases is fairly simple and is already implemented in every lime plant: Take the quantity of lime produced during a certain period and set it against the weight of new refractories installed during that same period. This gives you a very good KPI: refractory consumption in kg/t of product.

This calculation is used to verify designs and to obtain interesting feedback from customers. Some customers have implemented this benchmark for quite a number of kilns, which lends statistical significance to the findings. The customers compared the refractory life of rectangular Maerz kilns with a direct crossover channel to circular Maerz kilns with a suspended cylinder.

The figures obtained confirm Maerz’s design: whereas the direct crossover channel kiln uses more than 1 kg refractory per tonne of lime on average, the suspended cylinder design results in the very low consumption figure of 0.3 – 0.5 kg/t: Design approved, money saved.

3 Dealing with complex data

What if you have access to a huge quantity of complex data available at your fingertips?

Maerz believes in the philosophy of not “reinventing the wheel”. Hence it promotes well-proven and readily available software based on industrial standards. This gives the customers the full flexibility they need in daily business and also provides enough extensibility to incorporate other parts of their lime plants.

Only by following this philosophy may customers be sure to be supported by a large community updating and bug-fixing software within the shortest possible time.

4 The Maerz monitoring system

Maerz decided to follow the industrial communication standard “Open Platform Communication” developed by the OPC foundation, which is widely approved in the industry by major players such as Siemens, Rockwell, Modicon and many others.

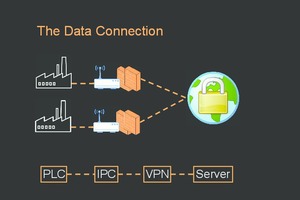

The data are acquired from the customer’s PLC by an IPC, which transfers them through a firewall via VPN to a cloud server. The system’s architecture is designed in such a way that several plants in different locations can report to one server, so that a comparison of data from various locations and therefore benchmarking can be performed easily.

Under the hood, the system relies on the German software Acron by Videc for data collection and as a database tool, which is controlled by the web application June5, also by Videc, for visualization and interaction.

Acron features an excellent reporting tool, which allows compilation of the data the customer would like to see even without programming knowledge. It further provides a sophisticated archiving function permitting the accessing of highly compressed historic data and comparison with online data – just in case the customer would like to do some benchmarking.

Acron also provides data summaries in any given time span to generate daily, weekly, monthly or yearly reports.

Complementing these advantages, June5 emphasizes detailed administrative options, which allow unparalleled user management: the customer administrator may define which user has access to which data, so that customized information may be easily provided relevant to a lime plant’s typical user groups: operating staff, maintenance teams, sales teams and also the management.

Everything is accessible via a web application – on any device. The customer may read the data and interact with the kiln from almost anywhere. And, of course, the customer may enter offline data such as laboratory results and other important information for correlation with the kiln process.

5 What about data integrity and security?

Here Maerz follows a clear strategy: the customer data belong to the customer. The customer’s administrators have full control over any access to customer data. A customer may, of course, share data temporarily with Maerz to facilitate remote support.

6 Where do we go from here?

It is obvious that a data monitoring system can only support the production process, but never replace a well-designed kiln and lime plant.

The new and enhanced data processing tools allow Maerz to better understand and control the lime-burning process. For the time being, the systems are designed to give only feedback to the kiln operators.

In a next step the monitoring system may propose operating set points, thereby limiting the “human factor”, which may lead to fluctuations in the kiln process, therefore possibly generating unnecessary costs for fuel and electricity.

In the not too distant future, a fully automated kiln operation is well imaginable: data collected online from the PLC in combination with data collected offline from laboratories and other sources may be the foundation for an expert system, which operates the kiln based on the best practice available in the industry.

//www.maerz.com" target="_blank" >www.maerz.com:www.maerz.com

Based on a lecture held at the International Lime Association Information Exchange

Forum, Cape Town, October 2018

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.