Grinding and calcining of gypsum with Pfeiffer grinding plants

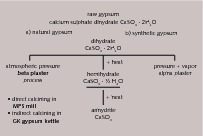

For the production of plaster products natural gypsum, synthetic gypsum or a mixture of both are calcined. Depending on the production process two different modifications of the hemihydrate CaSO4 x ½ H2O are obtained.

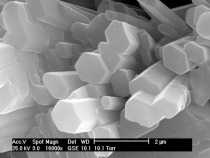

When gypsum is calcined in an atmosphere saturated with water vapour at an overpressure of several bars, a-hemihydrate is formed (Fig. 1). The outstanding feature of this plaster is a relatively regular crystal form. It is created due to the fact that the crystal water is able to escape from the intermediate lattice structure of the CaSO4 slowly and uniformly as escaping is greatly hampered by the counter-pressure built up by the water vapour.

Due to the relatively regular crystal structure and the large individual crystals of the a-hemihydrate, there are few contact surfaces for...

When gypsum is calcined in an atmosphere saturated with water vapour at an overpressure of several bars, a-hemihydrate is formed (Fig. 1). The outstanding feature of this plaster is a relatively regular crystal form. It is created due to the fact that the crystal water is able to escape from the intermediate lattice structure of the CaSO4 slowly and uniformly as escaping is greatly hampered by the counter-pressure built up by the water vapour.

Due to the relatively regular crystal structure and the large individual crystals of the a-hemihydrate, there are few contact surfaces for recrys--tallization when the plaster sets. Hence the setting time is relatively long. The bound mass has a relatively high strength. For these reasons a-hemihydrate is predominantly used for special applications (e.g. in medical technology). Usually, it is of too high a quality in the building industry.

The calcining of gypsum at ambient pressure and at a relatively low air humidity takes place much more frequently. The plaster obtained is b-hemihydrate. Its chemical formula is the same as that of a-hemihydrate. As, however, the crystal water escaping from the intermediate lattice structure encounters less resistance through the surrounding atmosphere, this process is almost like an explosion. Many fine needles can be seen under the microscope in the finished plaster. They act as recrystallization nuclei as the plaster sets, and its high number causes recrystallization to start relatively quickly during the setting process, resulting in shorter setting times.

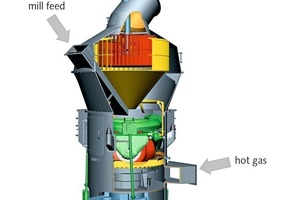

For the production of plaster products with b-hemihydrate, Gebr. Pfeiffer SE offers various machines and processes. One option is direct calcining in a Pfeiffer vertical roller mill of the type MPS-GC (Fig. 2). In this process, the gypsum is dried and ground to the required fineness of the plaster in the mill. Thanks to the relatively high temperature level in the gypsum calcining mill, the gypsum is simultaneously calcined.

The inlet temperature at the hot gas duct of this mill is usually about 600 °C while the gas temperature after classifier is set to about 150-160 °C. The mill is protected against the influence of the high temperatures by various heat protection measures.

The b-hemihydrate produced in the GC mill usually has an initial setting time of about 5-8 minutes. It is particularly suited for the production of plasterboards which require short but constant setting times.

Gebr. Pfeiffer SE has been supplying such GC mills since 1999, among others, the world’s largest two gypsum calcining mills. These mills of the type MPS 2800 GC with an outer grinding track diameter of 2800 mm produce more than 90 t/h of plaster for the production of plasterboards.

To make sure that the plaster has a longer setting time, the percentage of water vapour in the atmosphere during the calcining process must be higher than in the gypsum calcining mill. This is the case when the gypsum is calcined indirectly in a Pfeiffer GK gypsum calcining kettle.

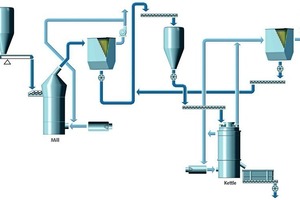

In this process, the natural gypsum is first fed to a Pfeiffer MPS mill where the material is dried and simultaneously ground to the required fineness for plaster. Subsequently, the ground and dried gypsum is delivered to the gypsum kettle (Fig. 3).

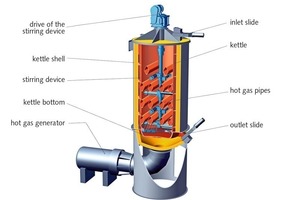

The kettle filled with finely ground gypsum is heated from outside. To improve the heat input, hot gas pipes lead the hot gas straight through the kettle (Fig. 4). The escaping crystal water causes the gypsum to start fluidizing as soon as it is filled into the kettle. The crystal water must rise upwards around the gypsum grains to the top of the kettle where it is sucked off into a dust collection plant. The fluidized mixture formed from the evaporated water and the gypsum decreases the bulk density and causes the mass in the kettle to be mixed intensively. This fluidization, which is supported by a stirrer, ensures that the introduced heat is very uniformly distributed in the kettle (Fig. 5).

Gypsum calcining kettles often operate batch-wise because plaster produced in continuous operation has a somewhat shorter setting time due to the product containing particles that are not completely calcined. The kettle is filled once and the material is then heated to the required temperature of about 150-160 °C. The plaster obtained in this process is discharged into a buffer silo from where it is taken to other plant sections for further processing.

When calcining takes place in the gypsum kettle, the water vapour content around the gypsum crystals is higher than it is with direct calcining. The crystal shape so created is somewhat more uniform but still in the form of needles. This process lengthens the setting time of the b-hemihydrate produced in the gypsum kettle to about 12-20 minutes without the addition of retarders.

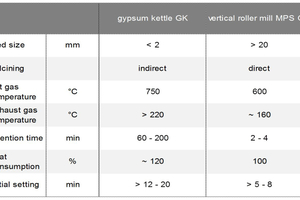

The dwell time of the plaster produced in the gypsum calcining mill is about 2-4 minutes. This is short in comparison to the time it takes in the gypsum kettle which may range between 60 and 200 minutes. Due to the kettle being heated indir-ectly the specific thermal energy requirement is about 20 % higher than when the gypsum is calcined directly in the gypsum calcining mill (Tab 1).

The quantity of the water to be evaporated in the calcining process also plays an important role. A low purity degree of the feed material requires less water to be evaporated which causes the production rate of the gypsum kettle to increase.

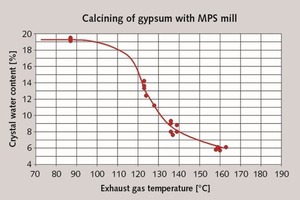

The production rate of the gypsum kettle as well as the specific thermal energy requirement can be additionally influenced by partial calcining in the mill. The gypsum is then not only ground and dried in the MPS mill but also heated to such an extent that a small quantity of crystal water is eliminated. The content of the crystal water in the intermediate product can be set relatively precisely by choosing the gas temperature after the mill (Fig. 6).

If the crystal water content obtained during partial calcining is not lower than 8-12 %, the plaster produced in the gypsum kettle has the quality features of kettle-produced plaster. Only when the partial calcining degree is higher does the plaster leaving the kettle resemble a plaster produced in the GC mill.

Partial calcining in the mill reduces the dwell time in the gypsum kettle because less crystal water needs to be eliminated there. This is reflected in an increase in the production rate. At the same time the thermal energy requirement of the overall plant decreases as a larger part of the total energy required is consumed in the mill in the direct calcination process.

Gypsum kettles of different sizes have been part of the Gebr. Pfeiffer SE’s range of products since 1963. The largest gypsum works with gypsum kettles has been in operation in Saudi Arabia since 2008 where an MPS 180 B vertical roller mill for partial calcining and two GK 300 A gypsum kettles, arranged in parallel, produce up to 600 tpd of high-quality plaster.

By choosing the suitable manufacturing process, the quality of the plaster can be influenced in the production stage in such a way as to reduce the rather costly addition of adulterants like retarders, or accelerators.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.