Encapsulation and controlled release of Cr(VI) reducing agent: application in ready-mix mortars

Raw materials for clinker manufacturing can contain chromium which from the iron ore in the kiln feed, to the mortar bag, remains as a potentially dangerous presence. For more than 60 years, soluble chromates have been recognized as being responsible for allergic contact dermatitis, a typical professional disease that affects construction workers. In 2003, the European Community released the Directive 2003/53/EC that requires that cement and cement-based materials produced or imported in Europe do not release more than 2 mg/kg (part per million – ppm) soluble chromates when mixed with water. As a consequence of this directive, cement produced or imported in Europe is treated with suitable reducing agents that can eliminate soluble chromates.

1 Introduction

The manufacturing process of Portland cement is standardized and widely described in several publications [1]. Raw materials (usually limestone and clays, with some aluminium and iron) are quarried (or obtained from the recovery of waste materials), then properly blended and ground in order to prepare the so-called raw mix. This is used as feeding for the pre-heater tower and rotary kiln, where silica and lime (with alumina/iron oxides used as flux) react in a high temperature process to form the calcium silicates that compose the Portland clinker.

Clinker is then finely ground...

1 Introduction

The manufacturing process of Portland cement is standardized and widely described in several publications [1]. Raw materials (usually limestone and clays, with some aluminium and iron) are quarried (or obtained from the recovery of waste materials), then properly blended and ground in order to prepare the so-called raw mix. This is used as feeding for the pre-heater tower and rotary kiln, where silica and lime (with alumina/iron oxides used as flux) react in a high temperature process to form the calcium silicates that compose the Portland clinker.

Clinker is then finely ground together with gypsum and secondary mineral additions (such as limestone, fly ash, granulated blast furnace slag, natural or artificial pozzolans) in order to obtain the well-known grey powder usually referred to as Portland cement, used by millions of construction workers as hydraulic binder in concrete, mortars, screeds, grouts and many others masonry applications.

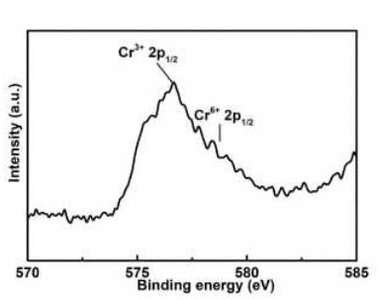

Unfortunately, raw materials for clinker manufacturing can contain chromium that, in the highly alkaline and oxidizing conditions of the rotary kiln, is partially converted to hexavalent chromium and fixed as soluble chromate: hence, from the iron ore in the kiln feed, to the mortar bag, chromium remains as a potentially dangerous presence. For more than 60 years [2], soluble chromates have been recognized as being responsible for allergic contact dermatitis, a typical professional disease that affects construction workers. In 2003, the European Community released the Directive 2003/53/EC that requires that cement and cement-based materials produced or imported in Europe do not release more than 2 mg/kg (part per million – ppm) soluble chromates when mixed with water [3]. As a consequence of this directive, cement produced or imported in Europe is treated with suitable reducing agents that can eliminate soluble chromates.

2 Hexavalent chromium in ready-mix mortars

Ready-mix mortars are ready to use, cement-based powder products for several building applications. They are formulated with cement, fine aggregates such as siliceous sands or carbonate and a wide range of additives depending on the properties and use of the mortar: strengths, durability, workability, control of air content, frost resistance, shrinkage/expansion and so on.

Ready-mix mortars are cement-based materials: they can contain soluble chromates that come from the Portland cement used in their formulation. Consequently, they need to be treated for Cr(VI) elimination. In some cases the reducing agent already contained in cement is enough, but quite often a further addition is needed. In fact, in comparison to Portland cements, the reduction of hexavalent chromium in ready-mix mortars could sometimes be a more challenging task:

Ready-mix mortars usually have longer shelf lives: consequently, the reduction of soluble chromates should be as long as possible. It is quite common to guarantee at least six months or one year reduction stability. It is a normal practice indeed to sell ready-mix mortars in bags, that are intended to stay on the market for very long periods of time.

Ready-mix mortars are hardly used in closed circuit batching operations, as happens sometimes with concrete. Screeds, grouts, renders are required to be handled by workers, who cannot avoid coming into contact with the fresh mix, and being exposed to a higher risk of allergic contact dermatitis.

Ready-mix mortars are widely used for applications in which esthetics play a key role: color variation due to staining must carefully avoided.

While the addition of reducing agent during cement manufacturing is perfectly feasible with liquid additives, ready-mix mortars are produced by blending different powders, thus requiring a reducing agent in powder form.

As a consequence, a suitable reducing agent for hexavalent chromium in ready-mix mortars should be highly resistant to oxidation and to all degradation phenomena that can reduce its efficacy after prolonged storage. Additionally, it should not promote any staining or variation of the color of hardened surfaces and it must be easy to incorporate during powder blending, even at low dosage.

Antimony compounds, proposed and developed for the reduction of hexavalent chromium in cements [4], certainly possess the aforementioned characteristics of high efficacy and long term reduction and absence of side effects. Unfortunately, the use of antimony compounds in powder form can be potentially dangerous. Several antimony compounds are harmful and the concerns are usually associated with the inhalation of fine dusts. This risk is completely eliminated with the use of liquid formulations from which dust release is impossible, but during blending operations (and in particular during ready-mix mortar preparation) a liquid product would not allow a correct and uniform addition of reducing agent while, on the other hand, the addition of powder antimony compound would leave the risk of dust formation, release and inhalation. This is why, until now, the development of powder products based on antimony has been severely limited.

3 Encapsulation and controlled release technology

Mapei efforts in R&D and the constant cooperation with the main producers of antimony compounds recently succeeded in overcoming this limit by developing the controlled release technology, which consists of the encapsulation of antimony compound in a special polymer: this allows the complete elimination of fine dust and allows the use of this reducing agent in a completely safe way.

The polymer is chosen in order to be quickly soluble in alkaline media (such as cement-based materials gauge water) and, as soon as cement is mixed with water, the antimony compound is released and expresses its full reducing power.

The use of this so-called “encapsulation/controlled release” technology (widely used in the pharmaceutical industry) presents several advantages:

The antimony compound is completely embedded in the polymer matrix, thus avoiding any possibility of dust release.

The particle size distribution can be carefully controlled, with total elimination of the finest fraction. Some antimony compounds are very fine (in some cases 100 % particle size distribution is below 10 µm). By producing a suitable encapsulated product, the presence of free antimony is completely eliminated and the finest fractions can be completely cut.

The possibility of tailor made products in terms of particle size distribution. Depending on the addition point of cement (in the grinding mill, at separator level, in powder blenders, during cement bagging or elsewhere), different particle size distributions may be required, ranging from finer (20-200 µm) to coarser (100-500 µm) ones.

The antimony compound maintains its superior performance, but the risk associated with inhalation is strongly reduced. The particular morphology of encapsulated antimony can be evidenced using advanced microscopy techniques.

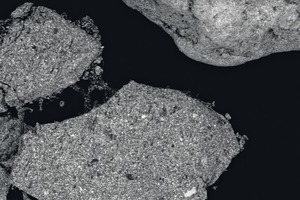

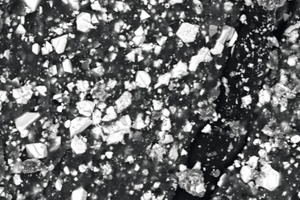

Figure 1 a and 1 b represent SEM (Scanning Electronic Microscope) images of a typical additive consisting of encapsulated antimony compound. In particular, Figure 1 a shows a 130 times magnification: the particles dimension is around 500 µm. Figure 1 b at a much higher magnification (4000 times) that shows the antimony compound (white crystals, dimensions in the range of a few µm) completely embedded in the polymer matrix (that appears darker). When the polymer comes into contact with alkaline water, it dissolves very quickly releasing the antimony compound.

Figures 2 a and 2 b show a similar product, with a higher content of antimony. The elimination of finest fractions (and the absence of particles that can be easily inhaled) can be demonstrated by determination of the particle size distribution, through laser diffraction. Particle size distribution is a graph reporting the content of each individual particle size in a powder, in the function of particle diameter.

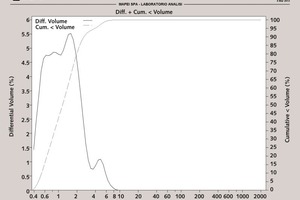

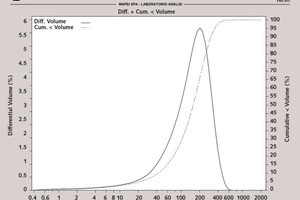

Figure 3 a shows the particle size distribution of a typical high fineness antimony compound. All the particles are smaller than 10 µm: inhalation of such fine particles can be very dangerous due to possibility of reaching the lungs. If this powder is encapsulated in polymer, the final dimension can be carefully controlled and the finest fractions can be removed: Figure 3b shows the particle size distribution of a powder additive based on encapsulation/controlled release technology. Particle dimensions are between 20 and 600 µm and the finest fractions are no longer present.

4 Conclusions

The controlled release technology based on encapsulation of reducing agents in a polymer matrix can be successfully used in order to prepare innovative additives. In fact, the elimination of soluble chromates in ready-mix mortars is usually harder than in Portland cement, due to stringent requirements of long lasting efficacy: the antimony compounds possess the superior technical performance, but are in some cases difficult or dangerous to handle in powder form. The encapsulation of the antimony compound in a suitable soluble polymer allows maintenance of the performance, strongly reducing the risk.

//www.mapei.com" target="_blank" >www.mapei.com:www.mapei.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.