Efficient gas clean-up for the cement industry

GEA ECOpuls technology significantly betters emissions limits, with simultaneously high ease of maintenance, low pressure drop and ultra-low energy needs. The basis for this is the constantly further-developed GEA low-pressure bag filter with its rotating cleaning system.

1 Introduction

ECOpuls technology, with its rotating cleaning manifold, is used around the globe, in the cement industry, among others, for the dedusting of kiln/raw-mill gas, clinker-cooler gas and bypass dedusting. Clean-gas dust content of below 5 mg/Nm³ and even less can be achieved with certainty using this well-proven technology. The term “zero-emissions system” has correspondingly become firmly and rightly established.

Bag filters achieved recognition as the “state-of-the-art” technology decades ago. Existing electrostatic precipitators have since then correspondingly been converted to...

1 Introduction

ECOpuls technology, with its rotating cleaning manifold, is used around the globe, in the cement industry, among others, for the dedusting of kiln/raw-mill gas, clinker-cooler gas and bypass dedusting. Clean-gas dust content of below 5 mg/Nm³ and even less can be achieved with certainty using this well-proven technology. The term “zero-emissions system” has correspondingly become firmly and rightly established.

Bag filters achieved recognition as the “state-of-the-art” technology decades ago. Existing electrostatic precipitators have since then correspondingly been converted to bag filter systems. ECOpuls technology is eminently suitable for such conversion, thanks to its compact design. This also offers the benefit that the original filter casing can still be used, thus making it possible to save half of the conversion costs. The flexibility of the GEA ECOpuls filter system is illustrated here by means of two examples (new filter system vs. conversion).

2 GEA ECOpuls bag filter

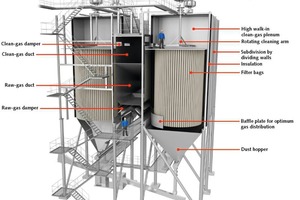

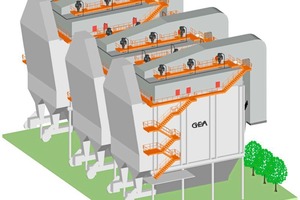

The ECOpuls bag filter (Fig. 1) convinces with its low pressure drop and high cleaning efficiency, which is also reflected in low operating costs. The GEA ECO-puls bag filter can be installed in single-line configuration (Fig. 2) or as a double-line filter (Fig. 3), depending on the available space. The two types differ in their gas routing. In single-line configuration, the dirty-gas and clean-gas ducts are fitted at the sides. The double-line arrangement is characterised by a raw-gas/clean-gas duct located at the centre.

The ECOpuls filter is divided in principle into individual chambers (each with a raw- and a clean-gas zone), which can be isolated by means of damper valves. This design makes it possible to isolate individual chambers from the gas flow (e.g. for maintenance reasons, so called on-line maintenance). Both the tubesheet and the clean-gas zone can be produced in stainless steel where there is a danger of corrosion. Up to 1200 filter bags are installed in each chamber. The bags are of a basic elliptical shape, with a length of up to 10 m, and are arranged in a number of concentric circles. The dimensions of the filter bags conform to the tried-and-proven GEA standard and thus permit the installation of maximum filtration surface area per unit of enclosed space.

The filter bags are effectively regenerated at 0.8 bar by means of a rotating cleaning manifold (Fig. 4). This design has the advantage that only one cleaning valve is needed for each chamber (i.e., one valve for up to 1200 bags). Thanks to the rotation of the cleaning system, cleaning is a systematic but random, and therefore stochastic, process. This means that, across a prolonged period of time, all bags are cleaned with uniform frequency. The necessary compressed air is generated using commercially available Roots-type blowers. All components, such as the pulse-diaphragms and the drive/actuation elements, are easily accessible from outside and are installed on the baghouse roof, considerably simplifying maintenance work.

Entry to the clean-gas zone can be accomplished without difficulty and in a maintenance-friendly manner via side doors. Unlike conventional filter types, labour-intensive dismantling of covers/insulation cassettes and blow pipes is not necessary. On the one hand, sealing surfaces are thus reduced to a minimum and false air, and the resultant corrosion, are no longer a problem. And, on the other hand, bag changing takes only 60 % of the time otherwise necessary. In addition, the high walk-in clean-gas chambers are designed in such a way that split bag-support cages can be removed and installed easily and generate only minimal flow resistance.

Reliably reacting broken-bag detectors are installed in every chamber in order to improve operating reliability and permit rapid detection of defective bags.

2.1 Bag-filter function

The particulates-laden raw gas firstly passes through the raw gas duct and then via the open raw dampers into the individual filter chambers. It firstly strikes baffle plates, which protect the bags against direct wear and assure optimum gas distribution within the housing. Approach flow is essentially horizontal across the entire length of the bag, with a minimum vertical component (the so-called “can velocity”). The dust captured on the bags forms a dust cake, which is removed from the bags as a function of differential-pressure and time control.

2.2 Cleaning

A 0.8 bar low-pressure pulse of air is generated by means of diaphragm/solenoid valves via the compressed-air reservoir installed for each chamber (Fig. 5). The compressed contents of the tank, of up to 1.5 m³, is fed to the bags via continuously rotating cleaning manifold. Such systems typically consist of three cleaning arms, below which slot-shaped nozzles are fitted on the outlet side. The flushing-gas flow per filter bag is approximately equivalent to fourfold that of conventional high-pressure filters.

The bags are inflated across their entire length by the pulses and are then effectively flushed through. This operation takes place on-line, with no interruption to filtration. This energy-saving variant, which is also used on long-bag filters of 10 m in length, directs the energy of the cleaning operation more directly onto the bags, and renders high-pressure/off-line systems obsolete. The pressure pulse is applied more gently, and thus permits longer filter-bag service lives. The filter’s operating costs are thus permanently reduced.

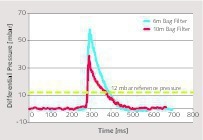

The high overpressure on the filter bag achievable using this process (Fig. 6) is used with low losses for cleaning. The complex preparation of compressed air, including drying, and other components for pressure reduction, all otherwise necessary in high-pressure systems, are not needed here. A further advantage of low-pressure technology is the utilisation of the temperature rise to approx. 80° C occurring at compression. A temperature drop below the dewpoint is thus avoided with certainty during cleaning.

3 Installation of a new GEA ECOpuls filter

Little space, a tight time-schedule and high safety standards are the boundary conditions that confront the GEA team on many projects.

The order recently completed at a German cement plant comprised the installation of an ECOpuls bag filter, a new stack with an induced-draught blower, an automatic pre-coating system and all the connecting piping.

Use of the largest possible elements (e.g. side walls supplied and installed in one piece) and modular construction means that many components can be pre-assembled at ground level and then installed as a single large unit. This, of course, minimises difficult and complex work at great heights.

Installation here took around four months, and “flame-to-flame” reconnection was accomplished within three weeks. This reconnection operation included the installation and insulation of the new dirty-gas ducts, and also the installation of a media gantry. One particular challenge was the installation of the raw-gas duct (“gooseneck”) (3.4 m in diameter, length: approx. 25 m, see Fig. 7). This connects the outlet from the existing conditioning tower to the inlet of the bag filter.

All deadlines were met, and commissioning was completed with no problem.

4 Conversion of electrostatic precipitator to bag filter

The conversion of electrostatic precipitators to bag filters has been “state-of-the-art” technology for decades. The existing filter housing continues in use in such cases. Only the filter house roof needs modification, to permit accommodation of the tube bundle, complete with clean-gas plenum, on the one hand, and a new clean-gas duct, on the other hand. This procedure makes it possible to save around 50 % of costs compared to installation of a complete new filter. Around twice the reconnection time (4 to 6 weeks) is needed for such a conversion project, however. Corresponding pre-assembly of the clean-gas plenum at ground level makes it possible to reduce the necessary reconnection time to a minimum, however. Here, the new clean-gas plenum complete with tubesheets is assembled at ground level (Fig. 8) and lifted by a crane onto the existing filter housing (Fig. 9) for installation. The compact design and low number of connections outside the gas zone predestine the ECOpuls filter for the conversion of electrostatic precipitators without any need for radical changes to the existing structure.

An electrostatic precipitator does not have a split raw-gas/clean-gas plenum, and this must therefore be retrofitted. For this purpose, the clean-gas plenums, consisting of the tubesheet and dividing walls, are integrated into the existing housing. For conversion projects, the behaviour of the gas flow is determined in a computational fluid dynamics (CFD) study and the raw-gas/clean-gas duct modified and guide plates installed correspondingly.

As shown in Figure 10, in this example the clean-gas duct is mounted on the top of the filter. Low particulates-emissions limits can thus be met at calculable and rational cost levels.

5 Conclusions

The GEA ECOpuls bag filter, with its adherence to all promised properties and its availability combined with ultra-low operating costs and clean-gas figures close to the detection limit, exhibits conformity to the very highest industrial standards. Its innovative design makes maintenance work easy, thus differentiating this system from more complex high-pressure systems.

Thanks to its more than 100 years of experience and its large range of completed installations, GEA is a reliable partner around the globe for industrial-scale gas cleaning and environmental protection in general.

The compact design of the ECOpuls bag filter mean that it can be used flexibly, whether in confined spaces in single-line configuration, compact double-line configuration, or for the conversion of existing electrostatic precipitator installations.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.