Efficient crusher drive composed of standard and individual components

Hazemag & EPR GmbH (Hazemag) based in Dülmen is among the leaders when it comes to the construction of crushing plants. For the retrofit of a limestone crushing facility in France, Hazemag developed the Hazemag Center Sizer HCS 1020 with two counter-rotating rolls. For the drive, the company used Integrated Drive Systems (IDS) including two helical gears from Siemens. The major benefit of this solution is the combination of standard components and individual elements which simplifies both maintenance and engineering, as well as cutting delivery times.

When it comes to crushing plants for the industrial treatment of primary and secondary raw materials, the specialists at Hazemag & EPR GmbH (Hazemag) based in Dülmen, southwest of Münster in Germany, can draw on experience gathered over a 170-year long company history. Alongside the crushing rolls, in these machines first and foremost the gear plays a decisive role. The gear solutions required are generally extremely complex and require a very long delivery period. Different conditions applied to a recent retrofit project in France, in which an obsolete jaw crusher was replaced by a Center...

When it comes to crushing plants for the industrial treatment of primary and secondary raw materials, the specialists at Hazemag & EPR GmbH (Hazemag) based in Dülmen, southwest of Münster in Germany, can draw on experience gathered over a 170-year long company history. Alongside the crushing rolls, in these machines first and foremost the gear plays a decisive role. The gear solutions required are generally extremely complex and require a very long delivery period. Different conditions applied to a recent retrofit project in France, in which an obsolete jaw crusher was replaced by a Center Sizer (HCS) fitted with an Integrated Drive System (IDS) from Siemens.

1 Optimum stone sizes and high throughput

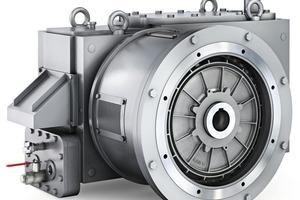

Hazemag was tasked with developing a solution with a higher performance capacity which would also be capable of optimizing the geometric shape and size of the stones after crushing to an average of 90 millimeters. If stones of an insufficient size are produced (less than 40 millimeters), they are sieved out. If they are too large (oversized material), the process of calcination in the lime kiln cannot be completed. Calcination is a chemical process whereby solid materials are decomposed or water removed by means of heating. “This solution allowed us to reduce the fine content of the crushed product by five percent, and also to significantly limit the proportion of oversized material,” reports a delighted Jochen Emmerich, responsible for the Center Sizer at Hazemag. The HCS solution, which combines standard technology and individual elements, comprises two rolls which counter-rotate towards the center at a rate of 37 revolutions per minute, and an IDS including two H3SH helical gears from Siemens. The rolls have a diameter of one meter and are two meters long, and allow the HCS 1020 to achieve a throughput of around 700 tons of limestone an hour. This project saw the installation of a one-piece welded steel housing for the H3SH15 gear size for the first time at Hazemag, increasing overall rigidity and reducing the risk of leaks. Compared to split versions, this housing also offered the greater compactness necessary to meet the restricted space available in this application. The steel housing was additionally constructed with a shortened rear dimension, which allowed the specified center distance of just 850 millimeters to be adhered to. “This allowed us to place the helical gear units to be installed just a few centimeters from each other, which made for a tangibly simplified overall design of the HCS,” explains Emmerich.

2 Future-proof set-up

Another decisive benefit of this gear solution is the use of standard components individually adjusted to the customer’s needs. The modular system this created at Hazemag can be adopted with minimal added input – in other words lower engineering costs and short delivery periods – for other crusher configurations in the future. The connection to the three-phase induction motors was also standardized, using an internally developed coupling lantern screwed to the gear housing, creating a highly maintenance-friendly design. Torque transfer from the motors to the helical gears takes place using a Siemens fluid coupling type Fludex FGD 565. The hydraulic couplings dampen load peaks without reducing torque and compromising crusher performance. This prevents damage to the drive train due to the high kinetic energy of the motors and short-term blockages during the crushing process. This function uses the breakdown torque of the motors, which in the HCS deployed in France can reach up to 4.4 times the rated torque level. “This system structure saves the need for enormous flywheels of the type required by other crushers,” says Emmerich, who is enthusiastic in his summing up of the benefits: “Due to the overall design based on standard elements, with this gear solution we are able to build even bigger crushers without requiring a major re-engineering process.” On this basis, the Center Sizer could easily be implemented with rolls 1.30 meters in diameter and four meters in length, meaning that the company is ideally set up to meet the changing requirements of the future.

//www.siemens.com/ids" target="_blank" >www.siemens.com/ids:www.siemens.com/ids

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.