Digital replaces paper

The control and instrumentation (C&I) systems of processing plants generate an almost overwhelming torrent of data, and paper-based documentation no longer has a rational basis. The integration of manufacturer portals into engineering tools now generates significantly more benefits for plant operators.

1 Introduction

Good documentation is essential in modern commercial-scale plants, both during the construction phase as well as during subsequent operation. In the process industry, in particular, plant engineers and operators are confronted with multiple challenges, due to the large number of control and instrumentation (C&I) components installed in the facility and the vast range of documents for every measuring point. Tracking all of the necessary documents up to commissioning is a complex task, and keeping them up to date during on-going operation is no less demanding. As recent as a few...

1 Introduction

Good documentation is essential in modern commercial-scale plants, both during the construction phase as well as during subsequent operation. In the process industry, in particular, plant engineers and operators are confronted with multiple challenges, due to the large number of control and instrumentation (C&I) components installed in the facility and the vast range of documents for every measuring point. Tracking all of the necessary documents up to commissioning is a complex task, and keeping them up to date during on-going operation is no less demanding. As recent as a few years ago, reservations concerning digital solutions were still widespread, however, now most plant engineers, operators, and component suppliers universally agreed (a rare occurrence): paperless documentation is the future.

It depends, of course, on the particular type of plant, but many processing plants have several hundred to several thousand measuring points – and every single one must be documented. The plant operator has to collect, review, check, and sort documents supplied in “hard-copy” (= paper) format, and then, provide access to them in a rational form. Furthermore, the same C&I components are in many cases installed multiple times, often hundreds of times, in some plants. And then hundreds of copies of the documentation are also supplied. At one end, there is someone using a photocopier to assure quick access to the documentation in the many areas of the plant where it is needed while, at the other end, someone is disposing of waste paper on an almost industrial scale. Thus, digital documentation, implemented in the ideal case in such a way that the information from the manufacturer portals can be directly integrated into the engineering tool, would be the most desirable solution. However, the solutions currently available for digital documentation could, in fact, be the reason that “digital” has not yet become conclusively established. The two routes – supply of data on CDs and access via the Internet – both involve drawbacks and difficulties.

2 CDs and the Internet are only a partial solution

Documentation CDs are generally compiled non-automatically: all the documents for a specific shipment have to be assembled and copied from the supplier’s IT system onto a CD. This manual activity takes time, which is why the CDs bearing the vital documentation often arrive at the customer’s facility after delivery of the hardware components. Another drawback: documents on CD are “final” and cannot be updated.

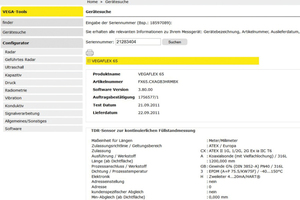

This time lag is eliminated when the manufacturer supplies his information via the Internet. The time required to obtain data is still not insignificant, however. It is necessary to find the relevant documentation, to review the individual pages of the supplier’s website, and to enter long, multi-digit serial numbers. This process has the inherent risk of natural human-errors occurring via typing mistakes. The worst situation is when a “typo” finds the documentation for a similar, yet incorrect, piece of equipment, and the error is not noticed. In addition, this time-consuming search procedure has to be repeated for every device installed (Fig. 1).

Whether the data is obtained on a CD or from the Internet, every document still has to be linked to the right component in the engineering tool and then stored at an appropriate location. The time necessary for this should also not be underestimated.

3 Direct engineering-tool,

access to the manufacturer’s portal

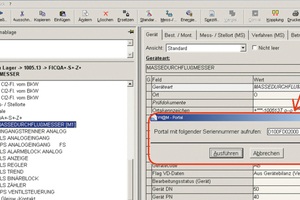

There is another way: C&I components can be registered in the engineering tool by means of various data as early as the planning phase. It would, therefore, be ideal if data on the particular component could be obtained directly from the supplier using the engineering tool. Rösberg’s automation experts have integrated a corresponding solution into their Prodok PCS-CAE system.

If the serial number has already been stored, it can be used for the search; otherwise, it can be entered in the search mask, and then adopted directly into the engineering tool. Then, when the “portal” button is clicked, it links the system automatically to all documents available from the supplier (Fig. 2). These generally take the form, for example, of operating manuals (precisely matching the particular instrument variant and driver version), materials certificates, calibration records, approvals such as WHG or SIL, declarations of conformity, ATEX certificates, and parametering records.

The instrument supplier must make this information available on a corresponding portal if this link is to work. The interfaces between Prodok and the manufacturers’ portals are known both to the manufacturers and to Rösberg. Linking is thus extremely simple, since this work has already been fully completed for manufacturers, and now only needs to be entered.

4 Off-line data access

Additionally, Prodok also makes it possible for the user to download all of the documents and store them locally. The system assigns the documents to the appurtenant measuring points automatically.

Such direct linking of the engineering tool with the manufacturers’ portals generates multiple benefits simultaneously: the overall time requirement for document management is cut significantly. Human input errors, and the concomitant risks of accessing incorrect documents, are simultaneously reduced. The additional ability to download the data means that the problems mentioned initially – collecting, reviewing, checking, sorting, and presenting documentation – are completed in a single operation. New and amended documents can also be automatically downloaded if a manufacturer has retrospectively updated them because errors in the documentation have been found, for example, or because a component has been modified.

Downloading also means that the user is no longer dependent on the supplier and can use the documentation even if he or she is not on the Internet at the time (Fig. 3). This generates great benefits in the case of maintenance work in the plant, in particular. A combination with the Livedok electronic documentation system (Box) significantly facilitates the updating of documentation during the plant’s operating life-cycle. Changes to the relevant documents can be made in off-line mode – using a tablet PC, for example – and then synchronised with the documentation on the server.

5 Less time – and less stress

The integration of manufacturers’ portals into the engineering tool has long ceased to be purely theory, and has proven its worth in practice. One satisfied user is Matthias Segschneider, an Evonik Industries AG Site Service electrical, control and instrumentation (EC&I) operations engineer at the company’s Wesseling location. As he notes, “We were involved in accelerating the integration of manufacturers’ portals from the very start. We set up communications between a number of manufacturers and Rösberg, and successfully achieved a prompt solution”. Today, as Segschneider comments, everyone is pleased with just how much that solution has made their lives easier. The system saves up to 45 minutes per measuring point that was needed to copy the information into the relevant documentation. “Not to mention easier documentation updates throughout the plant’s life-cycle”.

Segschneider is extremely pleased that the portal solution has made procuring spare parts significantly easier. “I look forward, in the long term, to a clear progression toward digital documentation. In the future, in addition to buying good components, good documentation in a format that can be rationally edited is going to be more and more important”, he adds. In Segschneider’s view, the manufacturers already supporting such portal solutions will be joined by many, many more in the mid- to long-term future. And that will mean much less “paper-pushing” for both manufacturers and users.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.