Data-base replaces data-islands

Planning and design of large-scale facilities for processing of basic resources is a complex task involving many diverse challenges. The fact that “plans” are no longer the focus of everything here may sound paradoxical, but it is already an everyday fact for a number of plant engineers. Claudius Peters (CP), specialising in bulk materials and process engineering is one of them. The company has restructured its engineering activities and made a new success story of them.

The starting point of CP’s ideas for modernising its engineering processes was the desire for better data networking and better tools than had been used up to now. The result was an innovation project aimed at further strengthening the CP group to face major challenges in the 21st century. A system was therefore sought that would assure continuity across discipline boundaries, permit easy access to knowledge, and significantly shorten processing and project completion times, while simultaneously improving quality.

Claudius Peters “home markets” are in the cement, gypsum, coal, steel and...

The starting point of CP’s ideas for modernising its engineering processes was the desire for better data networking and better tools than had been used up to now. The result was an innovation project aimed at further strengthening the CP group to face major challenges in the 21st century. A system was therefore sought that would assure continuity across discipline boundaries, permit easy access to knowledge, and significantly shorten processing and project completion times, while simultaneously improving quality.

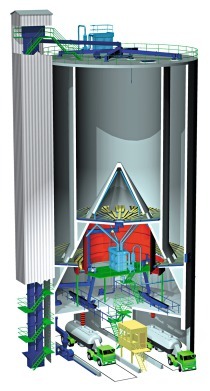

Claudius Peters “home markets” are in the cement, gypsum, coal, steel and aluminium industries. This more than 100-year-old company conceives and produces storage solutions, handling and conveying systems, silos, grinding and packaging machines, gypsum homogenisers and bulk materials technology for ships, aluminium and coal. The globally active Claudius Peters Group GmbH centres on the town of Buxtehude, in northern Germany.

“Expectations met to the full”

After thorough research, the bulk materials experts decided on an old familiar friend. At that time, CP had already been using Aucotec software for project planning for more than twenty years. Now they were convinced by the potentials of the modern, data base-founded Engineering Base (EB) software platform, and also by the supplier’s technical advisory services and conversion support. The system has now been in operation for a good two-and-a-half years, including utilisation by many users on major projects. “Our expectation that the obstructions to the workflow caused by the previous data-islands, consisting of multiple tools, would be eliminated has been met to the full”, comments Thomas Nagel, Operations Director at group member company Claudius Peters Projects GmbH. “It’s no longer a question of whether something can be done, but only of how to do it”.

Rethinking

A complete new start was ventured with the EB project, and the retention of existing data was not an option, due to the new function-orientated view of P&IDs and basic planning. “The approach that EB generates necessitates rethinking, but ultimately results in considerable time-savings and in significantly higher-quality documentation”, reports Ulrich Cord, Group Manager Automation and head of the EB project. The electrical engineering side did not, initially, save any time, however, since restructuring demands were higher than previously. Standardisation using the function-orientated “Typicals” stored in the central data-base greatly enhanced planning effectiveness, however. And: new employees were familiarised and trained quickly and with no difficulties.

The new functional view now also harmonises perfectly with the internationally binding IEC 81346 systems structuring standard. “We first had to evolve understanding of the standard-compliant aspects of ”Function“, ”Location“ and ”Product“ and their correlations. Now, however, we have a consistent designation system for process and electrical engineering and we can even harmonise it with customers’ systems, such as RDS-PP, among others, by simply switching over”, notes CP manager Cord.

“Building interdisciplinary bridges”

Even only very shortly after an initial introductory workshop held by Aucotec, the planning engineers were able to gain practical experience with the new system in a pilot project. “We just simply got started, using 100 % standard EB, with no customisations”, relates Nagel. Key users, and those from the departments affected, then together set their “Claudius-Peters path” for future engineering. “System optimisation alone is not enough, you have to take the employees with you”, Cord comments.

Drastically reduced effort for designation changes, back-traceable and easy association of the specified plant aspects, trouble-free processing of a project by twenty users simultaneously, and automatic display of information in lists, drawings and data sheets with just a single entry - all this is available on one decisive platform: the data base integrated into EB. It ensures, as the “single source of truth”, that all plant model data is up-to-date at all times, for every user, everywhere.

As Ulrich Cord states, “We wanted to move from paper processes to the document world. We are now undergoing a process of change initiated by the

Aucotec platform. For us, it’s a success story even now”. EB has built interdisciplinary bridges, he notes, and changed the engineering communications culture. “Heads get together earlier and closer now”, says this automation expert. Cord affirms that process and electrical engineers’ understanding of each other has been greatly boosted thanks to immediate insight into the working results of the other disciplines. As Cord states, only this new, data based assisted planning procedure has shown just how inefficient the old sequential route was, by scheduling the work of the various disciplines to run in parallel.

“From the plan to the data”

Reinhard Knapp, Senior Product Manager at Aucotec, explains: “EB shifts the engineering work from the plan to the data. It is then no longer document-centred, the data itself is the focus, including all its interlinkings”. A plan is then only one of the possible ways of viewing the plant model, not necessarily the starting point. Objects can be generated and processed purely alphanumerically, and the graphical representation is generated largely automatically. “We now no longer think in documents, but in an object-orientated way, instead. Our focus is on smart utilisation of our centrally acquired data sets, which must then interact with each other. They can’t do this if they’re contained only in dead, separate plans”, Cord continues, while Nagel adds: “Aucotec has made us understand what data is. And that is the future!”

EB sets standards

Following implementation of the new system, the bulk materials experts’ focus is now on standardisation. The central task is to “pre-think” and structure components, assemblies and sub-systems rationally. Once stored in EB, such ready-to-use standards will further shorten processing times considerably.

EB will also improve the interaction of company-wide software tools and further reduce redundant updating of data. The ERP and 3D link - bidirectional and including linked objects - is planned for the near future. “By networking data and tools, we have triggered a radical change in our IT landscape”, Nagel affirms. A project entitled “Inspired Excellence”, examining ideas for 3D linking, was launched immediately after the presentation of EB to the company management. This project is to further accelerate optimisation of planning and design processes and the software landscape.

“Inspired Excellence” includes not only continuity from Sales/Marketing up to and including Aftermarket Service, maximum possible avoidance of redundant data, shorter processing times and greater quality in all project phases, but also preparation for current trends, such as Industry 4.0. EB is thus also setting standards in the broader sense.

4.0 – a future topic

CP already has its sights on real-life implementation of Industry 4.0. The fact that the engineers consider EB right for this is attributable, again, to its data-base foundation. CP’s engineers know that nothing can be started for Industry 4.0 without this. “Systems and machines only begin their lives after the planning/design phase, where an ”engineering“ system usually ends. Our aim is to interconnect operating and error data with the planning data. EB has already demonstrated that this system can provide extremely efficient support for this. And we intend to put this to good use”, concludes Thomas Nagel.

//www.aucotec.com" target="_blank" >www.aucotec.com:www.aucotec.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.