CompGlass – First results with fibre glass reinforced cellular concrete

The objective of the described study was to investigate the feasibility of glass fibre reinforcement of cellular concrete. Particular aims were to demonstrate a method of fibre-glass preparation, a process technique and the properties of the new compound material.

1 Introduction

1 Introduction

2 State of the art and basic idea

Another patent involves the use of fibres on the basis of polymethylpentenes [3]. These close fibres remain unaffected even under autoclave conditions, so that they make a significant contribution to increasing the strength of the cellular concrete. However, despite the successful implementation of the method in the industrial production process, the produced compound material has not been able to assert itself on the market. It is doubtful whether the manufacturing process on the basis of a catalytic reaction under high pressure is really cost-effective.

The use of glass fibre for concrete reinforcement purposes is not a new approach [4]. The reproduced autoclave alkali test demonstrated alkali-resistant glass fibres (AR glass) and also proved the suitability of carbon fibres. However, polypropylene material appears unsuitable for this application. Commercially standard AR-glass contains > 15 % zirconium oxide (ZrO2). Due to the fact that this material is very expensive, cost-effective utilization of this glass has so far not been possible.

The basic idea of the young researchers was to use ordinary generally available glass on the basis of alkali-earth alkali-silicate glass as a reinforcement element. This would do away with the need to use the expensive alternatives such as glass with a high ZrO2 content, carbon fibres or plastic fibres. However, the glass dissolved during the autoclave process due to its poor alkali-resistance. Therefore, a glass with a refined surface had to be used.

3 Results

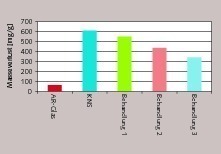

To evaluate the suitability of the surface refinement process, alkali resistance tests were performed. For this purpose, a specific quantity of fibres (of known surface) were weighed and then subjected for one hour to attack by an alkali mixture (pH = 12.8) in autoclaves. The subsequently determined loss in mass, compared to the initial material and AR-glass was used as the evaluation standard. Fig. 1 shows some selected refinement results.

The AR-glass included for the purpose of comparison shows that the refined glass fibres have not yet reached the desired standard. The criterion was achievement of at least the resistance of the AR-glass. The best refinement method (treatment 3) improved the resistance of the float glass by a factor of 2, but still did not achieve the resistance of the AR-glass. For this reason, all the reinforcement tests were initially carried out with AR-glass fibres only. We melted and spun these ourselves in accordance with set compositions.

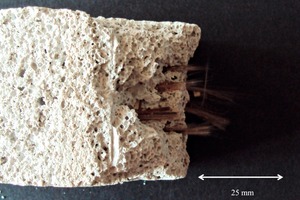

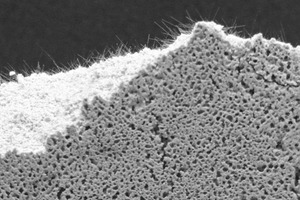

By using a dispersion disk, which can also be used in an industrial-scale operation, it was possible to achieve uniform distribution of the fibres. During this phase of the investigation it was discovered that it was not only the quantity of fibres but primarily the interaction between fibre length and fibre diameter that was decisive for a uniform distribution. If these parameters are not observed, it is impossible to achieve a homogeneous distribution. The formation of fibre bundles shown in extreme form in Fig. 3 was a frequently experienced phenomenon. The fibres were not dispersed throughout the cellular concrete cake but concentrated in the form of a central strand. This form of fibre distribution not only damages the cutting tools but also destroys the strength improvement effect of the reinforcement. The strands partially act as a defect point with reduced strength. It is therefore essential to assure uniform distribution of the fibres.

Numerous tests were therefore carried out in order to determine the precise interrelationships within the framework of statistical test planning. Up to now, the following parameters have proven to be the most suitable for the fibres of our own manufacture:

Fibre diameter 30 µm

Fibre length 2 cm

Maximum fibre quantity 2 % (referred to solids content).

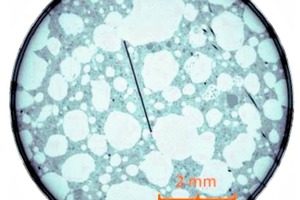

As microscope photographs always show a two-dimensional detail of the sample at the fracture surface, whereas a view into the structure of the material would provide better knowledge of the fibre distribution, images were produced using a computer tomography scanner. Fig. 4 shows one such image. Evaluation of the obtained CT pictures by image analysis from different directions of view revealed that the fibres are three-dimensionally distributed. There is no preferential direction. This means that the fibre alignment is not negatively affected by the expansion process. More-over, the possibility of extreme bubble propagation due to the introduction of new interfaces at the fibres can also be excluded. Such bubble propagation would have eliminated the desired effect on the material‘s strength.

Parallel to the practical testwork, mathematical-numeric simulations were carried out. These enabled very precise prediction of the fibre distribution and the expansion characteristics. Details can be obtained directly from the authors.

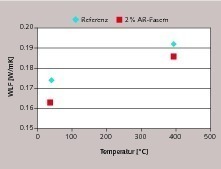

In addition to the bulk density, the low thermal conductivity of cellular concrete is a significant characteristic that makes the use of this building material worthwhile. We therefore investigated the influence of the glass fibres on the thermal conductivity at room temperature and also at approximately 400 °C. The results of these tests are shown in Fig. 5. Contrary to expectations, no deterioration in the thermal conductivity characteristics could be found. Instead, the values were actually slightly reduced, so that the material‘s heat insulating properties improved. To provide comparability, the determined bulk density values were also recorded. Both the samples were prepared from identical mixture formulations, but the fibre-reinforced sample nevertheless showed a significantly lower bulk density. The reduction in thermal conductivity is therefore not caused by the fibres in themselves, but by the improved stability of the cake resulting from the fibres, which leads to a lower bulk density. This in turn is directly proportional to the thermal conductivity. It is evident that the fibre reinforcement has no negative effect on the thermal conductivity of the cellular concrete. Even at temperatures just under 400 °C, the differences are still present, which is of importance if, for instance, the cellular concrete is to be used for regenerator construction.

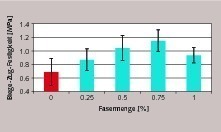

The aim of the reinforcement was to achieve an increase in strength of the samples. For this reason, bending-tensile tests were carried out. The samples used for these tests had dimensions of 50 x 50 x 200 mm. The centre distance of the 3-point bending support was 150 mm. Prior to the tests, the bulk densities of the samples was determined. Each depicted strength value is supported by at least 15 samples, in order to provide statistical certainty. For all the tests, the samples were prepared over the entire expansion height in order to minimize the influence of expansion.

Fig. 6 shows the influence of the quantity of fibres on the strength of the cellular concrete. As was to be expected, the strength of the cellular concrete rises in line with an increasing content of fibres. For these tests, AR-glass cut to a length of 10 cm was used for the reinforcement. Actually, the greatest strength value should be attained at a maximum additive quantity of 1 %, but instead of this the strength decreased again. This was the result of the already described formation of fibre bundles, which negatively affected the strength. On this basis, the optimum quantity of these fibres would be 0.75 % referred to the solids content. The associated bulk densities of the cellular concrete samples were approximately 0.46 g/cm3 and showed hardly any change after addition of the fibres.

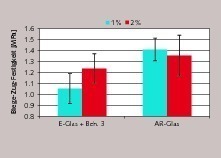

The influence of different types of fibre was also investigated. Aside from the AR-glass we also used so-called E-glass[1]. This is a type of aluminosilicate glass that is used in many fibre reinforcement applications. For our purpose, the surface of the E-glass fibres was refined by treatment method 3. For the tests, 2-cm-long fibres were used and addition quantities of 1 % and 2 % respectively were selected. Fig. 7 shows the results of these tests. In this case, too, it is noticeable that an increase in the quantity of fibres does not always lead to an increase in strength. In the case of the E-glass refined by a newly-developed method, there is obviously no formation of fibre bundles, even with an addition quantity of 2 %. This indicates a “benign” dissolution of the fibres, causing a loss of the actual reinforcement effect. For this reason, the samples reinforced with AR-glass are significantly stronger. However, the E-glass fibres seem to have a stabilizing effect on the cellular concrete, so that a finer pore distribution is achieved, resulting in an overall rise in the strength of the material.

4 Summary

The results were extremely promising. Success was achieved with the introduction of glass fibres into the cellular concrete without the formation of bundles. It was still possible to cut the green samples. Furthermore, a relationship was determined between the fibre addition quantity, the fibre diameter and the fibre length. This will provide an important basis for further investigations. In order to exclude negative influences, the development of bulk density and thermal conductivity were also investigated. In both cases no deterioration occurred in comparison with the values of the reference samples.

The fundamental aim of achieving an increase in strength was also realized. Depending on the employed glass fibre (i.e. length, quantity and diameter of the filaments) a strength increase from 0.3 MPa to more than 1.7 MPa was achieved without changing the bulk density. This means that the objective of 30 % strength improvement was more than achieved. The results also showed that there was no deterioration in the pore structure. At the same bulk density, significantly stronger samples were produced, or respectively a lighter material could be used while still observing the specified minimum strength requirements.

5 Prospects

The work of the young researcher group is financed by the European Social Fund.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.