Co-processing trial run with pre-processed Municipal Solid Waste fractions

With increasing urbanization Municipal Solid Waste (MSW) generation in Indian cities is ever increasing and its management is one of the greatest challenges for urban managers. Co-processing of dry reject fractions of MSW in cement kilns can address the need for environmentally sustainable management of solid waste as well as help to reduce the cement industry’s growing dependence on fossil fuel. The high temperatures and adequately long residence time in cement kilns also makes co-processing of pre-processed municipal solid waste, a viable option.

1 Introduction

Waste derived fuels have been co-processed in cement kilns for a long time and this practice is prevalent in developed countries. Many developing countries are also taking initiatives for co-processing of pre-processed non-recyclable and non-degradeable waste. There are few attempts in India regarding valorization of waste derived fuels in cement plants, by different cities but the system is still to be fully established. The reasons for this slow development is the lack of clear regulation on co-processing of waste derived fuels, absence of appropriate waste pretreating...

1 Introduction

Waste derived fuels have been co-processed in cement kilns for a long time and this practice is prevalent in developed countries. Many developing countries are also taking initiatives for co-processing of pre-processed non-recyclable and non-degradeable waste. There are few attempts in India regarding valorization of waste derived fuels in cement plants, by different cities but the system is still to be fully established. The reasons for this slow development is the lack of clear regulation on co-processing of waste derived fuels, absence of appropriate waste pretreating equipment and technical infrastructure in the cement industries, and coordination between the cement industry, urban local bodies (ULBs) and lack of capacity building.

In order to explore the feasibility of co-processing in cement plants and to analyse the commercial implications of co-processing in the field – Nashik Municipal Corporation (NMC), Geocycle & Ambuja Cement Ltd. (ACL) and GIZ (Deutsche Gesellschaft für Internationale Zusammenarbeit) conducted trial runs for co-processing at the Maratha Cement Works, Chandrapur, Maharashtra.

With an increasing population in urban areas in India, the management of MSW is increasingly becoming a problem for the urban local bodies. Land for landfilling is a major constraint in most areas in the country. Composting, which is the most common form of bio-recycling undertaken by most ULBs, caters only to the wet bio-fraction of MSW. Amongst other things a high portion of plastic got from MSW is sent for reuse and recycling while the non-degradeable rejects from the compost as well as the non-recyclable products, are sent to a “landfill”. In many cases final disposal is uncontrolled dumping which is very often a health hazard and nuisance for the neighbouring communities. It is the question whether this common practice of waste disposal needs overall improvement or there is the need to look for alternative final treatment options.

The recycling industry in India is one of the largest in the world. Recycling of plastics happens to the tune of 47 % of the total production [1]. After collection of the portions that can be recycled by mechanical recycling, there remain numerous fractions in the rejected stream like plastics (heavily contaminated articles, multi-layered composites, pouches, etc), jute, rubber, leather, rags, coconut shells etc., which are mostly unattended and allowed to remain in the waste stream, thus forming the large bulk of the municipal solid waste problem. References are available regarding the fact that developed countries are disposing these non-recycleable wastes after pre-treating through co-processing in cement kilns in a sound and environmentally friendly manner. References are also available for reutilizing these portions via incineration in RDF-power plants instead of uncontrolled dumping on landfills.

Recycling is of great importance in the context of municipal solid waste management and with the speed at which humans are consuming natural resources, it should also be mandatory for all. Recycling principally refers to recovery, which is divided into material recycling and energy recovery. Material recycling can be divided into mechanical and feedstock recycling. The choice between mechanical recycling, feedstock recycling or energy recovery depends on the type of waste and the rate of ease and difficulty in total or partial segregation from other waste materials. Pure grade production scrap may only have to be collected separately, reground and reprocessed, mixed wastes have to be mechanically separated and, if contaminated, in rare cases also elaborately washed and cleaned. All these steps increase the cost depending on the degree of contamination and the targeted demand for the waste material.

The efficient use of non-renewable fossil fuels, toxic residues and the contamination of water and soil resources are in the forefront of ecological concerns and public discussions. Cost competitiveness, global competition and profitability are the concerns of resource intensive industries. The challenge facing today’s society is to balance environmental protection and economic interest.

To demonstrate the co-processing methodology in the cement industry, the Indian Associated Cement Companies (ACC) had conducted co-processing trial runs of hazardous waste, including plastic waste at its Kymore cement plant, with the support and guidance from the Indian Centre for the Plastics in the Environment (ICPE). The results of the trial runs demonstrated that approximately 2 tph of fuel blend have no negative influences on the stack emissions due to the presence of high temperature and the long residence time of the kiln and also there was no impact on the product quality. After the successful trial runs, the process received legal sanction as part of the guidelines for co-processing of hazardous waste in cement plants published by the Central Pollution Control Board in 2010. All facilities under the Holcim subsidiaries ACC and ACL now have the provision of co-processing of hazardous waste including plastic waste within their premises.

To further explore the possibility of co-processing of other waste streams and to take this initiative forward, Geocycle (ACL), Nashik Municipal Corporation (NMC) and GIZ, under the Indo German Environment Partnership Program (IGEP) decided to work together on exploring the utilization of the dry-waste rejects from municipal solid waste composting comprising of plastics, jute, cloth, coconut shells, leather, shredded paper, rubber, etc. Nashik was selected for this initiative because of its integrated MSW management system. The MSW management processing plant in Nashik has adequate provisions for mechanical segregation of mixed waste and also includes a Residue Derived Fuel (RDF) plant within the facility. This paper gives an overview of the co-processing methodology, presents the results of the trial run for the co-processing of dry reject fractions of MSW and provides the potential for usage of the methodology in India.

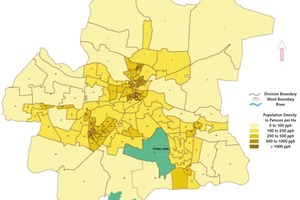

2 About the city of Nashik

Nashik is located in the northwest of Maharashtra State in India. Referred to as the “Wine Capital of India”, it lies on the banks of the river Godavari, on the Western Ghats close to the western edge of the Deccan peninsula. Nashik is the administrative headquarters of the district and is located 180 km from Mumbai and 200 km from Pune. According to the Census of India, 2011, the population of Nashik Municipal Corporation numbers 1 486 973 people (Fig. 1). The total area of Nashik is 259 km2, which makes it the fourth largest urban area in Maharashtra in terms of population. It is the third most industrialized city in Maharashtra after Mumbai and Pune.

3 Municipal solid waste management

Nashik Municipal Corporation (NMC) was established in 1982 and is responsible for managing the services in the city of Nashik including solid waste management, water supply, sewerage, roads etc.

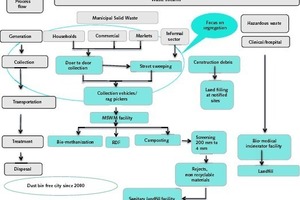

The NMC has a very well-defined system of MSW management. The Corporation collects 350 to 400 metric tons of MSW per day from the city through designated vehicles and processes them at the integrated MSW processing plant.

NMC has been successfully operating the door to door collection system for MSW within the city for the last 14 years. Initially, NMC only had a compost plant for processing of organic waste. In 2009, the integrated facility including an upgraded compost facility, RDF and sanitary landfill, etc. were established under the Jawaharlal Nehru National Urban Renewal Mission (JNNURM) of the Ministry of Urban Development, Government of India. The current facility is designed to handle up to 500 tpd of incoming waste. The disposal management of MSW including the waste streams with the process flows in the city of Nashik are broadly explained in Figure 2.

The MSW disposal system in NMC is divided into two parts. The collection, segregation and transportation of MSW are managed by the Health Department while the processing and landfill is managed by the Mechanical Department.

3.1 Collection, segregation and transportation in Nashik

NMC has outsourced the collection and transportation of MSW in the six divisions of the city comprising of 122 wards. The collection from each ward is done by hydraulic vehicles so-called ghantagadis (Fig. 3). There are 130 ghantagadis that have been outsourced to private operators for door to door collection of MSW. The Ghantagadis cover around 300 000 households every day for collection of waste. Each Ghantagadi is installed with a GPS system, there is online monitoring of the vehicles and a daily report is generated for monitoring purposes.

3.2 Processing and landfill

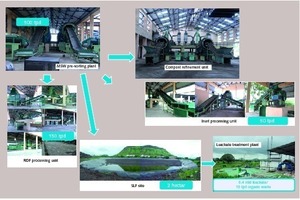

The integrated MSW processing plant at Nashik includes mechanical pre-sorting, inert processing, RDF facility, aerobic windrow composting, sanitary landfill pocket, leachate treatment facility and animal carcass incinerator (Fig. 4). The existing facility has the capacity to treat 500 tpd of MSW. The RDF facility can process 150 tpd of waste and the inert processing facility has a capacity of 50 tpd. The sanitary landfill is spread over an area of two hectares.

4 Co-processing in the cement industry

4.1 General co-processing in the cement industry

Co-processing is the thermal use of alternative fuel and the clinkerization of minerals and ashes for the purpose of energy and/or resource recovery [2]. Co-Processing refers to the use of waste-derived materials in industrial processes, such as manufacturing of cement or lime, or any other large thermal processes. The main objective of co-processing is recovery of energy and material to substitute primary fuel and raw material by waste. It is a recovery of energy and material from refuse [3].

As countries strive for greater self-sufficiency in hazardous waste management, particularly in developing countries that may have little or no waste management infrastructure, properly controlled co-processing in cement kilns can provide a practical, cost-effective and environmentally preferred option to uncontrolled landfilling and cost-intensive waste incineration. In general, co-processing of waste in resource-intensive processes can be an important element in a more sustainable system of managing raw materials and energy [2].

4.2 Co-processing in India

The Indian cement industry is the second largest in the world with a total installed cement capacity of about 320M tpy, production of 220M tpy and approximately 181 kilns. During 2006-2011, the annual growth rate over the five-year period was 9 %, according to the Cement Manufacturers’ Association 2011 Annual Report.

Infrastructure and housing demand have provided development opportunities and the government’s plan to double infrastructure expenditure is expected to sustain industry growth at a similar pace in the coming years [4].

In 2012, the Indian cement industry consumed more than 356 Mt of virgin raw materials, over 25 Mt of coal and 18 billion kWh of electricity. Waste recovery and coal replacement in the cement industry has only been practiced for a relatively short time in the country. As such, the Thermal Substitution Rate (TSR) is still below 1 % [4].

In 2010, the Central Pollution Control Board (CPCB), Government of India, defined the framework for co-processing of hazardous and non-hazardous waste under the “Guidelines for Co-processing in Cement/Power/Steel Industry”. The guidelines cover hazardous waste as well as non-hazardeous waste. Amongst other things the hazardous waste category includes paint sludge from the automobile sector, petroleum refining sludge, TDI (toluene di-isocyanate) tar waste and ETP (effluent treatment plant) sludge from chemical industry. The other wastes category includes plastic waste and tyre chips. The guidelines also restrict the use of biomedical waste, asbestos containing waste, electronic scrap, entire batteries, explosives, corrosives, mineral acid wastes, radioactive wastes and unsorted municipal garbage from co-processing, which disturb the kiln process [5].

Indian cement majors such as ACC, ACL, Lafarge, Shree Cement and UltraTech are involved in co-processing activities with hazardous waste. India’s top two cement producers, ACC and UltraTech, reached a TSR of 0.59 % and 0.47 %, respectively as of February 2011 [6].

About 25 cement plants have started co-processing of hazardous and non-hazardous waste in India. But the TSR is still less than one per cent for the non-hazardous wastes, too [5]. So far no data are available of the substitution rate for raw materials.

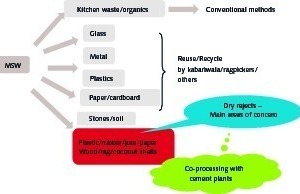

4.3 Why co-processing of dry segregated rejects of MSW?

Municipal waste is a heterogeneous material and consists in developing countries mainly of a native organic (kitchen refuse, green cut), an inert (sand, ash) and a post-consumer (packing material, electronic goods) fraction. Valuable recycling material such as paper, cardboard, hard plastic, glass or metal etc. are often sorted out by the informal (rag pickers & scrap dealers) or the formal sector (cooperatives). In some cases the organic fraction is used for biogas production (anaerobic digestion) or for composting. But even when all the supposed valuable material is extracted from the municipal waste stream, the dry residues have requisite calorific value for being co-processed.

A large untapped potential for fuel substitution in India seems to be with MSW and the possible production of waste derived fuel. Due to a lack of reliable inventories in India, MSW generation can only be estimated and it seems fair to assume a daily per capita average of 0.25 kg. With a total population of 1,21 bn people in 2011, this would translate to approximately 110 Mta of MSW [5].

Co-processing is also a preferred solution in the waste management hierarchy (Fig. 5). It is ranked higher than incineration and landfill, as it aims at the use of energy and material from refuse. Legally co-processing of waste if compared with waste incineration also has several advantages. The higher temperatures and residence time in the kiln results in efficient thermal destruction of even the most persistent pollutant. The alkaline lime-based environment in the kiln acts as an absorption gas cleaning. The biggest advantage is that co-processing of suitable pre-processed and proven fuels in a cement clinker process leaves no residue for disposal (refer to Table 1 for details)

Many cement companies in India have no experience with co-processing of alternative fuels and very few have targeted MSW and the possible production of Refuse Derived Fuel (RDF) [5]. However, more and more companies are gaining interest which is also the result of different promotional activities carried out by the Cement Association of India and the Cement Sustainable Initiative (CSI) of the WBCSD.

What is valid for industrial waste holds true also for municipal waste. Only sorted waste with a known composition and defined calorific value is suitable for processing as alternative fuels. The selection has to be based on the waste hierarchy and the social impacts of waste recycling as income generation for the urban poor. Whenever possible the informal sector should be incorporated in collection and sorting activities. As cement kiln emissions are site-specific, depending on production processes and the input material, a control and monitoring system for the in- and outcoming materials and for the optimization of the feeding points is an important aspect to be considered.

5 Co-processing trial run

for dry segregated rejects of MSW

As already stated, the existing guidelines for co-processing of hazardous waste in cement plants includes only plastic waste and tyres under the other wastes category and does not accept non-recyclable unsorted municipal waste. NMC, GIZ and the Holcim subsidiaries initiated the co-processing trial run exercise for addressing the issue of disposal of dry segregated rejects of MSW, including plastics. As a first step, the responsibilities of each agency were defined, in order to have a successful trial run. The following tasks were assigned to the partners.

5.1 Ambuja Cement Ltd. – Geocycle

ACL would support the selection and packing of suitable material for the trial run process at NMC through deputing its personal who would advise on the required quality and quantity of waste to be readied and transported for the trail run. ACL and NMC would take necessary approvals from concerned authorities for transportation of municipal solid waste and co-processing. ACL would bear the cost of transportation of the agreed quantum of five truckloads of pre-sorted dry MSW processed at the Nashik MSW processing plant at Pathardi, to ACL’s Maratha Cement Works located 760 km away, at Chandrapur, Maharashtra; undertake the trial run at the plant and maintain the physical and photo documentation of the process at the plant as well as prepare a documentation of the same.

5.2 Nashik Municipal Corporation

NMC would provide the five truckloads of pre-sorted dry combustible fractions like cloth, jute, plastic, paper, etc. with a moisture content < 20 % and calorific value of > 2,000 kcal from the MSW processing plant at Pathardi, Nashik to ACL’s Maratha Cement Works, free of cost. NMC would weigh the waste before transportation and maintain the records of the material processed and send to ACL for further documentation. NMC would also support the process of bagging of sorted municipal waste before transportation through its workers as specified and agreed by all parties i.e. in 300 mm X 300 mm size bags. NMC would support ACL in taking necessary approvals from the concerned authorities for transportation of MSW as well as for co-processing, if so required.

5.3 GIZ

GIZ would support NMC by providing the required quantity of bags for bagging of pre-sorted dry MSW processed at the MSW processing plant. It would support NMC as well as ACL in documentation of the baseline study on solid waste qual-ities and quantities in Nashik. It would support the overall process through documentation and dissemination of results through a workshop.

Since the trial run would be useful in terms of exploring the possibilities of co-processing of MSW processed in large cement industries as a utilization option for the dry pre-sorted rejects of MSW, NMC granted the permission to ACL and GIZ to undertake the trials and to ACL to take the required quantity of the pre-sorted municipal solid waste processed at the MSW processing plant to ACL’s Maratha Cement Works at Chandrapur.

5.4 Analysis of waste samples

Post the agreement of roles between the partners and as a first step, ACL tested 3-4 types of mixed waste samples including raw fraction and as feedstock for RDF products, fluff, and pelletized RDF from the plant at Nashik.

Analysis of various types of waste samples were carried out at the ACL laboratory located at Thane. Samples from various stages of processing of waste, that is, raw fraction as feedstock for RDF production, shredded RDF and RDF pellets, were collected by the ACL team from the Nashik MSW facility and sent for analysis for parameters such as physical assessment, chemical analysis, calorific value, hazardous material etc. Following samples were received at the RMPD division of Q&PD at ACC Thane from NMC to assess their feasibility for co-processing in cement manufacture. Figure 6 shows the various RDF samples and their analysis. Considering the ash content in all above samples, the samples were evaluated for their chemical analysis. The data of this is tabulated at Table 2.

The samples were tested in ACL’s laboratory for calorific content. As per results of the tests the calorific value of dry waste ranges from 1800-2500 kcal. For high segregation plastic waste, calorific value increased to >5000 kcal. Amazingly, results of the analysis showed that raw segregated dry waste has a higher calorific value as compared to RDF pellets and shredded RDF.

5.3 The processes at Nashik

5.3.1 Discussions and meetings

In order to discuss the various issues associated with co-processing and requirements from ACL and NMC, several rounds of meetings were held at Nashik with the Commissioner and NMC officials. GIZ technical experts and experts from the Holcim group visited Nashik to understand the ground reality and the processes to be undertaken during the co-processing trials. After field visits and analysis of waste samples in the laboratory for calorific content, as stated above, it was decided to use different kinds of waste processed at the RDF unit for co-processing. This would help in understanding the differences between the temperature and handling issues at the cement plant for different forms of RDF.

ACL therefore asked NMC to send dry segregated rejects of MSW in the form of RDF fluff/dry waste in bagged and baled forms. It was decided that for this trial run the RDF pellets would not be used as NMC did not have the requisite quantities.

5.3.2 Mechanical pre-sorting

In India, mostly mixed waste is transported to the waste processing facilities. This mixed waste is pre-sorted into wet and dry fractions. The wet fraction goes for compost formation and the dry rejects are then sent to the RDF unit for further preparation. This step also eliminates the inerts that are present in the mixed waste, to a large extent.

The transformation of waste into alternative fuels (AF) must meet certain requirements. Some types of waste cannot be used directly as AF. This step produces a waste product with defined characteristics that complies with the technical specifications of cement production and guarantees that the environmental standards are met (Fig. 7).

The MSW facility in Nashik has a mechanical pre-sorting unit for segregation of dry and wet waste into various sizes. After the sorting of waste, it was found that the moisture content of dry fractions of waste was higher than 20 %, and that there would be the need to dry the waste before further processing and making it ready for sending to the cement plant. The drying was done by sun drying.

This material typically comprised of jute, leather, plastic, cloth, rags, wood, coconut shells, paper, and any other material with calorific value, which are the rejects after the different level of formal and informal recyclers, like the scrap dealers (kabariwalas), the waste collection trucks (ghantagaris) and the rag pickers, had sorted the material from the MSW recycling streams.

5.3.3 Sun drying and preparation of the material

The next step was to sun-dry the segregated dry waste fractions. The MSW facility of Nashik has a concrete platform for sun drying of waste and the same was used for reducing the moisture content to below 20 %, as desired by the cement plant (Fig. 8 and 9). The pre-segregated dry waste was kept for sun drying for 5-6 days. After significant reduction in moisture content, the waste was transported for baling and bagging at a suitable location within the plant. Some waste was also sent to the RDF facility for preparation of RDF fluff.

5.3.4 Preparing the waste for transportation:

baling and bagging

Considering the distance between the ACL cement plant located at Chandrapur and Nashik (760 km), it was decided to prepare bales of pre-segregated waste in suitable sizes to increase the volume that could be transported to Chandrapur. The MSW facility of Nashik did not have the facility for baling and NMC workers were also not familiar with the baling equipment. Therefore baling work was outsourced to a local agency experienced in baling of agriculture and industrial waste (Fig. 10 and 11). But it was observed that preparation of bales from waste was very difficult, cost and time consuming and it required very experienced personal and workers. Further, because the waste was dry, there was a lot of dust that was generated during the process of baling, due to the presence of inerts still in the mixed waste. Four truckloads of bales were prepared from this material.

Initially when the baling was proving to be difficult, bagging of waste was also tried with cement bags. But the amount of waste that fitted into one bag was very limited as compared to the amount that could be baled at one time. Hence only a limited amount of waste was packed in bags.

RDF fluff that had been prepared from the dry sorted MSW rejects was also packed in bags. About one truck load of bagged RDF fluff and dry sorted waste rejects was prepared.

After baling and bagging of the required quantity of waste (5 truckloads), the material was transported to the ACL cement plant at Chandrapur for the trial of co-processing.

5.4 The process at the ACL plant

5.4.1 Opening and drying of bales and bags

The bales and bags containing MSW were in varying sizes and the quality of the dry MSW fraction was also not uniform. In addition, the size of the hopper of the cement kiln is also not very large. Therefore in order to make the feed uniform, the bales and bags needed to be opened (Fig. 12 and 13). The material was then kept for sun drying on a platform, for further reduction of the moisture content.

5.4.2 Shredding

Once the waste was dried, it was sent to the shredding unit to be shredded to a suitable size for feeding into the hopper (Fig. 14 and 15). After shredding, the waste was sent to the mixing unit.

5.4.3 Mixing with wheat husk

At the mixing unit, the shredded waste was further mixed with wheat husk with the help of a wheel loader, in order to increase the density and for easy flow of waste into the hopper (Fig. 16).

5.4.4 Feeding the mixture into the preheater

After the mixing of the shredded RDF with wheat husk, the feed was put into the specially designed hopper for feeding the RDF into the cement kiln (Fig. 17 and 18). The RDF was fed into the preheater and at regular intervals in order that there was minimum disturbance in the kiln. Temperature fluctuations were recorded and documented by ACL. Records were taken for temperature fluctuations in kilns and feeding of waste to the kiln was monitored accordingly.

The trial run was conducted successfully at the ACL plant at Chandrapur for five truckloads of RDF in 2013. The different categories of pre-processed segregated dry MSW did not disturb the process at the kiln.

6 Co-processing – potential and the way forward

For a successful pre-processing of MSW and co-processing appropriate cost sharing models need to be developed which are suitable to local conditions of both the Urban Local Body and the cement industry. Introducing co-processing in the cement industry requires open communication with all stakeholders. It is important to provide all the information that is required by the stakeholders in order to allow them to understand the purpose of co-processing, the context, the functions of each party involved, the technical requirement of the cement process and the financial limitations. Open discussions about good and bad experiences are part of transparency, leading to corrective actions. Co-processing can also be seen as a potential for efficient resource management, if properly applied.

6.1 Co-processing potential for the ULB and the cement industry

6.1.1 Urban Local Bodys

Co-processing is location specific for each ULB.

Appropriate segregation of waste into wet and dry components ensures maximum utilization of waste fractions.

Additional investments might be required for the ULB.

Waste can be sent as a feedstock to the RDF plants, which may be located on the cement site.

Compression/baling the high calorific fractions (either RDF products or segregated dry MSW fractions) helps in increasing the density of the material for maximizing the bulk during transportation.

Key benefits: Environmentally sound utilization of dry sorted rejects of MSW as well as RDF from plants leading to an increase in the life of the sanitary landfill, thereby decreasing pressures on land in urban areas.

6.1.2 Cement industry

Co-processing is location specific for each cement plant. The closer the distance between a ULB and a cement plant the more economically viable it is for co-processing.

Additional investments are required by the cement plant to manage the HCF feedstock and fuel streams

The better the quality of alternative fuels sent to the industry, the easier it is for the plant to come up with a homogeneous fuel mix that can be used in the pyroprocess of a cement manufacturing process.

Key benefits: Co-processing leaves no residue to be landfilled and it helps conserve non-renewable resources and contributes to a reduced global environmental footprint. It represents a sustainable solution for many suitable proven waste streams that cannot be recycled and ideally should not be landfilled, dumped or incinerated. It offers significant potential for reducing pollution and landfill space.

The financial modalities for using MSW in cement industries have to be discussed and agreed upon between all parties involved in a transparent manner. Co-processing is not an activity to be classified under corporate social responsibility alone but it must also be a commercially viable solution for the municipality and the cement company alike.

If a municipality decides for a cooperation with the cement industry it must be ensured that the signed contract considers for both sides a mid- to a long term partnership in order to reduce the risk of dependency.

6.2 Co-processing potential for India

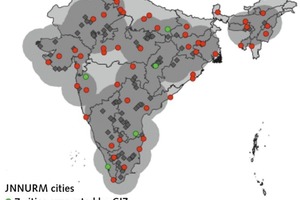

The potential of the cement plants with clinker facility in India that can be used for co-processing of dry sorted rejects of MSW was compared with the JNNURM cities. This was conducted as a desk exercise by GIZ.

The location of the 112 plants in India (Fig. 19) are shown having kiln facilities and the red and green dots are the location of the JNNURM cities. A buffer of 200 km was given to each plant, shown by the dark grey circles on the map. The buffer distances cover more than two-thirds of the country, showing the potential of co-processing in India.

Keeping in view the factors described in this paper and the demonstrated trial run, the cement plants have the potential to provide a solution for the dry reject waste types in the country.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.