From Municipal Solid Waste to energy

Municipal Solid Waste (MSW) as well as pure fractions of commercial industrial waste (CISW) can be pre-processed mechanically to “Carbon Verde (CBV)” in five steps. CBV can substitute 80 to 90 % of the pulverized coal or pet coke in cement kilns at Buzzi Unicem and helps to reduce GHG-emissions from uncontrolled landfilling and burning of fossil fuels.

Introduction

In most of the cases MSW is the undifferentiated portion of “urban waste” always present and newly produced every day. Treating MSW is on quite a different status in different countries and regions, i.e. in some countries of Northern Europe the benchmarking of municipal waste incinerators (MWI) depict the standard of treatment of any undifferentiated waste source.

However, incinerators have such a long lead-time, very high investment costs and are strongly opposed by public opinion. The existing landfilling therefore is still dumping the majority of MSW whereas additional new...

Introduction

In most of the cases MSW is the undifferentiated portion of “urban waste” always present and newly produced every day. Treating MSW is on quite a different status in different countries and regions, i.e. in some countries of Northern Europe the benchmarking of municipal waste incinerators (MWI) depict the standard of treatment of any undifferentiated waste source.

However, incinerators have such a long lead-time, very high investment costs and are strongly opposed by public opinion. The existing landfilling therefore is still dumping the majority of MSW whereas additional new landfilling areas are no longer permitted or are even subjected to EU fines when still depositing untreated and non-inert active bio-fractions.

In Italy, MSW is still disposed of either non-treated or mechanically separated into two fractions, which are the high calorific fraction and the biological, unstable fraction or is rarely sent to aerobic stabilization before sanitary landfilling.

In the Robilante cement plant of Buzzi (NW-Italy), the use of solid alternative fuels has been attempted for a long time as there were used tyres in the 80s, commercial fluffy SRF (residues of plastic and textiles) in the 90s, whereas from 2002 on – the plant moved to MSW-based SRF processed in three different versions.

SRF called “Carbon Verde” or “Carbonext” is the result of Buzzi´s research on a high-quality solid recovered fuel for their cement kilns and as the company believes for power plants as well, targeting on a very high (80 % or higher) thermal substitution rate (TSR) of pulverized coal or pet coke. The interest in the Carbon Verde process could grow in countries showing a similar situation to Italy i.e. trying to valorize large amounts of the MSW-based alternative fuels instead of taking them to municipal waste incinerators.

MSW energy content

In Italy over 32 million tons of MSW and approx. 50 million tons of CISW are produced annually. Usually, there is no perception of the huge amount of energy contained in MSW and CISW.

Assuming that about 25 million tpy of high calorific fractions of MSW and CISW could be processed resulting in 35 000 GWh, which are almost equivalent to 16 million tons of coal, which corresponds to approx. 10 % of the total energy consumption of Italy.

Furthermore MSW, as a perennial/ “renewable” source of energy independent of oil and coal prices, and is strongly in alleviating the difficult problem of unregulated dumping.

Production process

As mentioned above, CBV fuel originates from a mix of 70 to 75 % MSW and 25 to 30 % CISW and is obtained by processing such a mix by an innovative process developed by Buzzi Unicem in an existing waste treatment plant located in Sommariva B (Turin area).

The main features are: stability of net heat value and high fineness achieved by the grinding CBV process consisting of five steps or phases:

coarse MSW was shreddered to a 250 to 300 mm grain size

bio-degradation and stabilization of the total MSW by an aerobic process to reduce organic and its introduced moisture contend significantly

automatic sorting and removal of organic chlorine (PVC) with the help of near-infrared spectroscopy and

CISW addition, controlled by online NIR Spectroscopy analysis, for setting the desired caloric value

very fine grinding of the high calorific mix down to a fineness of 0.1 to 6 mm

The simplicity of the process layout is based on Buzzi´s chain mill being able to reduce the feed lump size of 300 mm to approx. 3 mm by just one passage (grinding ratio 100 to 1). This could turn into a significant advantage for cement plants wanting to perform the full process within their plant. They could look for a coarse and low value plastic mix, getting in this way a higher gate fee instead of paying for a fine shredded fluffy SRF (Fig. 1 and 2).

For bio-stabilization Buzzi Unicem favors the Biocubi® process which cuts down MSW moisture from 50 to 20 % and the bacterial flora to one tenth, so achieving with 14 days of aerobic digestion at 55 °C a fairly dry hygienic material (called Amabilis®) with a calorific value in the range of 12.5 to 16.5 MJ/kg (Fig. 3).

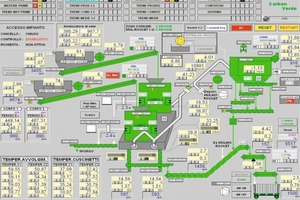

At the beginning of 2010, Buzzi´s first grinding equipment was installed and optimized as a flow process. The pilot plant consisting of a 2 t/h rocket with a fine grinding mill derived from a machine used for batch process to demolish electronic waste and household appliances (Fig. 4). The grinding system consists of chains connected to a hub rotating at 700 to 800 rpm. The chains can find different setups at the hub connection. The grinding plant is completely automated and equipped with a supervisory system (Fig. 5).

By optimizing the mill Buzzi Unicem managed to keep its energy consumption below 90 kWh/t input, which is indeed a high consumption, yet, acceptable for the desired fineness. At the end resulting in a fine product measuring between 0.1 and 6 mm with a high percentage below 1 mm, which is very much appreciated in view of an efficient combustion.

One year ago Buzzi Unicem installed a much larger mill with 5 to 6 t/h CBV capacity based on two grinding bodies. In 2013 its present output amounts to 12 000 t/a for one working shift or 24 000 t/a for two shifts, with the aim of increasing it to 40 000 t/a within the next two years, installing a second mill in parallel with the first one. This way Buzzi Unicem will be capable of processing the total amount of waste received by the Sommariva plant. In the proximity the landfill capacity for unsorted waste will be reached and will be going out of service in parallel (Fig. 6 to 8).

Fineness and combustion

It is surprising why such a high fineness is considered necessary, SRF in a high TSR are more difficult to burn as opposed to other alternative fuels such as solvents, oils and animal meals. Basically, fine grinding although increases energy consumption as well as in the case of pet coke grinding in order to achieve perfect combustion conditions.

Regarding the main burner combustion flame pattern, the temperature along the kiln axe axis and the kiln inlet temperature can be kept in line only using a fine product when the required TSR just by solid fuels increases to 70 to 80 %. Up to today, according to Buzzi´s knowledge such a high TSR is only achieved in the presence of hydrocarbon-based liquid waste and animal meat and bonemeal.

Regarding precalciner combustion: the CO level is dramatically reduced by using powderized CBV. Therefore CBV is particularly suitable for precalciners with a low retention time of 3 to 4 s (see Fig. 10 and 11).

Investment cost

A CBV medium-sized plant is designed to process 50 000 t/a MSW achieving 45 000 t/a of a high calorific final product. It can operate with different layouts and purposes according to the planned CBV using NB. Treatment plants for 100 000 t/a MSW and more are feasible as well as at lower unity cost. The investment costs for the two basic cases are:

Case a)

without bio-stabilization: Investment is in the range of 8 to 9 million € for only a grinding plant

processing a previously dried “light fraction of MSW”, excluding therefore bio-stabilizing, however including chlorine separation and CISW online controlled addition

Case b)

Including bio-stabilization: Investment is in the range of 20 million € for a 50 000 t/a MSW plant or € 400/t MSW.

This is the necessary process when the target consists also of complete elimination of the landfill.

Cost of operation

Case a)

The yearly cost for 8000 hours of operation, lies at approx. 3000 k€/a, broken down in labour k€ 600 + maintenance k€ 700 + electrical energy k€ 500 + freight k€ 500 + royalties k€ 500 + contingency k€ 200 = approx. 60 €/t MSW or approx. 67 €/t CBV, considering the CISW addition at breakeven. Depreciation at 500 k€/a over ten years accounts for approx. 10 €/t MSW.

Case b)

Introducing bio-stabilization, the additional costs for case “a” are 100 k€ labour + 500 k€ maintenance + 200 k€ electrical energy therefore reaching costs of approx. 4000 €/a equivalent to 80 €/t MSW or 90 €/t CBV. Depreciation of 1 million €/a over 20 years amounts to 20 €/t MSW.

Usually in Italy CISW is supplied with a disposal fee of 60 to 70 €/t which alleviate the CBV final cost in the range of 20 €/t CBV (an addition of 1/3), basically covering depreciation.

CBV production cost of 80 €/t MSW including depreciation, shows a saving of ca. 30 to 40 €/t MSW as opposed to the usual costs covered in Italy by the communities for MSW treatments.

Standards

CBV belongs in the category of solid recovered fuel (EWC 191210), which is in Italy called CSS = Combustibile Solido Secondario and regulated by CEN/ TC 343 (EN 15359) in accordance with the European Waste Directive 2008/98/EC.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.