Characterization and technical properties of high-performance CSA clinkers

The results presented in this paper are a fundamental part of the research work which has allowed Buzzi Unicem to achieve the product commercialisation of a CSA cement on an industrial scale.

1 Innovative binder on CSA basis

The present paper intends to present some of the most interesting aspects of the research work that has been carried out at Buzzi Unicem R&D laboratories during the development of a new calcium sulphoaluminate-based binder. In particular, a two-step methodology (Table 1) involving a preliminary lab-scale development followed by a pilot testing phase was adopted and will be presented, demonstrating the relevance and complexity of the entire assessment during the development of innovative building materials.

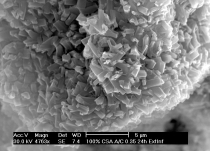

Laboratory equipment such as a thermogravimetric analyzer (TG), differential scanning analyzer (DSC) and X-ray diffractometer (XRD) was used for the preliminary laboratory tests, followed by several production runs in a pilot kiln, consisting of more than 50 kg of semi-industrial clinker each. The paper describes the technical properties of seven selected CSA clinkers produced in the pilot kiln by varying the burning temperatures, the SO3 content in the raw meal and in the cement and by testing the addition of additives. For each sample, evaluation of the burning behaviour was followed by TG/DSC analysis and the characterization of the resulting material by means of XRD analysis and compressive strength tests on the mortars were performed.

All the CSA clinker samples contained calcium sulphoaluminate (C4A3Sˉ) as the main component together with calcium sulphates, dicalcium silicate (C2S), tetracalcium-iron aluminate (C4AF), calcium sulphosilicate (C5S2Sˉ), calcium-aluminates (C3A, CA, C12A7) and calcium–silicoaluminates (C2AS, CAS2), CaO and MgO as minor phases.

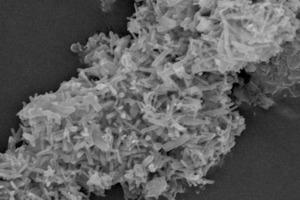

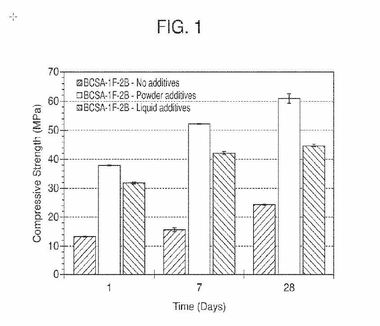

C4A3Sˉ is the main “hydraulic” phase of CSA cement and hydrates reacting with calcium sulphate to give ettringite (Fig. 1) according to the following reaction [4]:

2 Experimental approach

The second experimental approach started only when the lab scale tests were successful. A larger amount of raw meal (at least 50 kg) was prepared in a pilot ball mill in order to reach a reduced particle size (d95 < 120µm). The raw meal mix was then discharged into the pilot kiln hopper (Fig. 2) and transferred with a screw to the granulator plate (Ø = 0.7 m) (Fig. 3). The granulator plate, equipped with a water dispenser, added about 15 % of water with respect to the raw meal powder, producing spherical pellets. Once the pellets reached the desired particle size (Ø = 3–8 cm), they fell into the upper part of the rotary kiln. The pilot rotary kiln, originally designed for testing expanded clay production, consists of a pipe (length = 6 m, Ø = 0.6 m) lined internally with a refractory material and with a rotational speed of 1.5 rpm. The gas burner used CH4 as its main fuel with an average consumption of 15 m3/h, enough to achieve and maintain a burning temperature of about 1300 °C (Fig. 4). The kiln was equipped with an air cooling grid that was able to cool the clinker down rapidly and to reach a temperature of 200 °C in about 5 minutes. The raw meal feed was fixed at about 35 kg/h. The clinker pellets took nearly 70 minutes to run through the kiln and reach the cooling system. The quality control of the clinker produced in the pilot kiln was carried out carefully on pressed powder specimens -prepared with a Polab APM (Polysius) automatic pelletizer- analyzed by X-Ray diffraction. XRD analysis was performed approximately every 20 minutes using Bruker-D4 Endeavour apparatus working in u:u geometry, equipped with a ceramic X-ray tube KFF (Cu Ka radiation) and a LinxEye detector. EVA software was used for the identification of the main mineral phases, and the refinement for semi-quantitative analyses was performed by the Rietveld method [5] using the Topas 2.0 package (both pieces of software are commercially available from Bruker AXS). XRD analysis focused on the evaluation of the free lime and C4A3Sˉ content of each individual sample. The suitability of the Rietveld method for characterizing CSA cement was well demonstrated by Aranda et al [6]. A thermometric analyser permitted the temperature control of the kiln and the adjustment of the fuel feeding when necessary.

All CSA raw meals were prepared using limestone, bauxite, clay and gypsum as raw materials. In some cases, a small amount of bauxite was replaced by clay in order to improve the granulation quality. Sand was also used in a small amount in order to increase the SiO2 content when necessary.

Chemical analyses of the raw materials were performed by dispersive X-Ray fluorescence (XRF), using a Panalytical Axios spectrometer on fused bead. The specimens were prepared with a Breithländer autofluxer mixing 0.9 g of the calcined sample (950 °C) with Li-tethraborate in a 1:10 dilution. The resulting composition is summarized in Table 2.

Several formulations of raw meal (Table 3) were designed, with the aim of studying how the burning temperature, the use of doping agents and the SO3 content can affect both the mineralogical CSA clinker composition and the CSA cement mechanical properties.

Each single lot of clinker produced was then ground in a lab mill for 30 minutes; a Cilas laser granulometer was used for evaluating the particle size distribution; for all the clinkers d95 < 90 µm was found. Gypsum was added (5 %) to all ground clinkers.

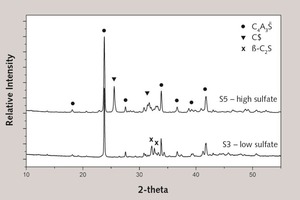

The effect of the amount of gypsum added during clinker grinding was also evaluated in the two clinkers (S3 and S5 clinkers, high and low sulphate respectively) by adding increasing amounts of gypsum. The mortar tests were performed according to EN 196-6 while the setting time was measured according to EN 196-3 using automatic VICAT apparatus.

3 Results

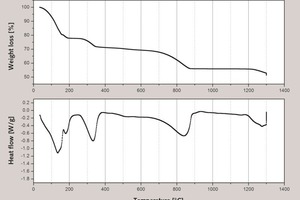

It is quite evident, as mentioned above, that the burning temperature must be correctly calibrated in order to allow the formation of the melting phase with minimum sulfate loss. The preliminary observations recorded in the TG analysis were confirmed by the pilot kiln burning tests. At a low temperature the pilot kiln was very powdery and dusty while as the temperature reached 1200 °C – 1250 °C, the pellets became sticky; some melted materials started to appear at 1270 °C, while, when the temperature passed 1300 °C, the acrid smell of SO2 (from the C4A3Sˉ degradation) could be perceived. Table 4 outlines the changes of the mineralogical composition of the CSA clinker produced at different burning temperatures.

The CSA clinker compositions are completely modified when passing from a burning temperature of 1170 °C to 1350 °C. At a low temperature, apart from the dominant presence of C4A3Sˉ and CSˉ, the presence of C5S2Sˉ is clearly evident, which disappears by increasing the temperature, leading to the formation of C2S and CSˉ. At a higher temperature C12A7 starts to form, as a result of the C4A3Sˉ decomposition.

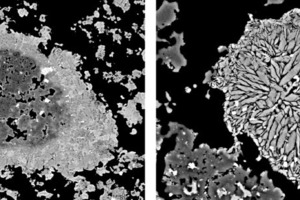

The testing of the bulk density of the clinkers, performed according to UNI 7549 (bulk unit weight of lightweight aggregates) supplies important information, useful for classifying the CSA clinker. At a low temperature, the samples are characterized by low bulk density and, subsequently, high porosity due to incomplete clinkering; on the other hand, at a high temperature the C4A3Sˉ damage leads to the formation of voids resulting from SO3 evaporation.

The burning temperature of the clinker also has a strong influence on the mechanical performance of the corresponding cement. Table 5 shows the results of the tests carried out according to EN 196-1 on mortars prepared by mixing each CSA with a fixed amount of gypsum. Considering that all samples contain significant amounts of residual anhydrite resulting from the burning process, 5 % gypsum was estimated to be sufficient for the complete C4A3Sˉ hydration [6]. The results of the mortar tests demonstrate that the clinker burnt at a lower temperature (1170 °C) has a shorter workability time and faster strength development than that burnt at a high temperature; on the contrary, the latter is characterized by a lower strength development velocity.

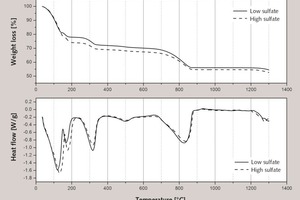

The XRD patterns demonstrate that high SO3 CSA clinker is characterised by an excess of anhydrite that appears as a significant peak on the right side of the main C4A3Sˉ peak (Fig. 6). TG/DSC investigations (Figs. 7 and 8) revealed that the SO3 amount does not significantly affect the clinkerization process and the melting temperature, the thermogravimetric curves being very similar for those concerning the heat development at different temperatures.

As regards the mechanical performance, the low SO3 CSA clinker is more reactive at an early stage, but it does not develop high long term strength unless a higher amount of sulphate is added to the ground clinker (Table 6). On the contrary, the high SO3 CSA clinker shows high strength development at a late stage, due to the fact that the necessary amounts of sulphate to allow the complete reaction of C4A3Sˉ are fully available. Moreover, both high SO3 CSA clinker and CSA cements containing high amounts of gypsum show delayed hydration and very slow strength development at an early stage. Raw meal with high SO3 content is definitely more delicate as, during the burning process, there is a higher risk of forming an undesired ring inside the pilot kiln.

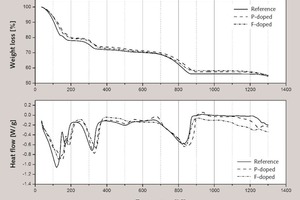

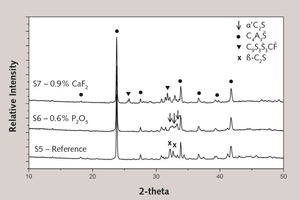

P2O5 and CaF2 introduce significant changes in the mineralogical properties of CSA clinker especially concerning the stabilization of C2S and the formation of fluorinate species such as fluorellestadite (C9S3S3CFˉ) and fluoro-aluminate (C11A7CFˉ).

Figure 9 shows the main differences observed in the XRD patterns of a reference CSA and two CSA clinkers produced with the addition of 0.6 % of P2O5 and 0.9 % of CaF2 to the raw meal (S6 and S7 respectively). The formation of the crystallographic modification a’-C2S , instead of the more common ß-C2S, is observed in the CSA clinker sample doped with P2O5 while fluorellestadite forms as a consequence of the following reaction in the presence of CaF2.

The same effect was observed during the pilot kiln burning test: the melting point of the CaF2-doped CSA clinker appeared at a lower temperature than the reference one.

In spite of the formation of a clinker with significantly different mineralogical phases compared to the reference one, the mechanical strengths and the setting time test (Table 7) revealed that the addition of additives does not produce any remarkable benefits; this is probably due to the two modified phases, a’-C2S and fluorellestadite, that are not involved in any hydration process.

4 Conclusions

The production of CSA clinker doped with foreign ions such as F and P, seems not to affect the mechanical strength development and the reactivity of the CSA cement. However, some beneficial effects can be noted during the production process when CaF2 is used: the reduction of the stickiness in the kiln and the mineralisation effect allow the lowering of the optimum burning temperature.

As a final remark, the authors intend to show the results of a long term investigation carried out on composition S1, which during the first series of pilot burning tests appeared the most reactive and interesting regarding the mineralogical composition. The compressive strength of clinker S1 has been prolonged up to an age of 8 years on a formulation also prepared using a water reducer. The test was performed in order to verify the stability in water of this particular clinker characterized by an unusual mineralogy and a very low burning temperature (1170 °C). The results are shown in Table 8 revealing outstanding performance and prolonged stability.

The use of the pilot kiln is an extraordinary tool for testing and developing innovative building materials on a pre-industrial scale. The results presented in this paper are a fundamental part of the research work which has allowed Buzzi Unicem to achieve the product commercialisation of a CSA cement on an industrial scale. The focus of the research on CSA binders is now more oriented towards the understanding of the hydration properties [10] and the durability [11] performance of these types of binders.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.