Building construction in the recycling system – concrete made with recycled aggregate in Switzerland

Resource-conserving building construction within the recycling system has been made possible in Switzerland by standards that are in step with current practice and through the willingness to undertake extensive research and development work. One example of this is the technical code of practice MB SIA 2030 for safe application of concrete containing recycled aggregate in concrete construction. Another example is the development of the resource-conserving Portland cement ZN/D 32,5 R. This has provided a new cement that closes the construction materials cycle by re-using local high-grade processed mixed granular material. This has made it possible to conserve natural resources, save landfill space and reduce emissions.

1 Introduction

Switzerland’s infrastructure would be virtually unthinkable without concrete. Of the nearly 1.5 billion t of construction materials that have been used in buildings, concrete accounts for more than half with over 800 t. Civil engineering accounts for a further 306 million t [1, 2].

Every year concrete production in Switzerland takes about 50 million t of gravel and sand. For years the policy in Switzerland has been to rely increasingly on concrete containing recycled aggregate to conserve gravel resources. Mineral materials from the dismantling of buildings are processed into...

1 Introduction

Switzerland’s infrastructure would be virtually unthinkable without concrete. Of the nearly 1.5 billion t of construction materials that have been used in buildings, concrete accounts for more than half with over 800 t. Civil engineering accounts for a further 306 million t [1, 2].

Every year concrete production in Switzerland takes about 50 million t of gravel and sand. For years the policy in Switzerland has been to rely increasingly on concrete containing recycled aggregate to conserve gravel resources. Mineral materials from the dismantling of buildings are processed into granular concrete material C and mixed granular material M. They replace part of the natural aggregate for producing concrete – so-called concrete containing recycled aggregate. In 2017 this concrete accounted for a market share of about 15 % of the total quantity of concrete produced in Switzerland. The technical code of practice MB SIA 2030 “Recyclingbeton” [3], which is currently being revised, ensures safe application of concrete containing recycled aggregate in concrete construction.

However, because of construction and environmental policy requirements, fine recycled aggregates (particle size group 0/4) from the processing of mineral construction and demolition waste may only be used to a limited extent in the production of concrete containing recycled aggregate. A large part of this material is therefore landfilled or used for the production of concrete components with low requirements (strength, durability). The search for alternative ecological ways of using this material has now resulted in the development of a cement in Switzerland that contains processed mixed granular material as a main constituent alongside cement clinker. This cement can be used in building construction in Switzerland as the result of progressive regulation of the technical standards.

2 SIA Code of Practice 2030 “Recyclingbeton”

for safe application of concrete containing

recycled aggregate

The term “Recyclingbeton” (RC concrete) is used in Switzerland to designate a concrete that contains at least 25 mass% recycled aggregate. A distinction is made between two types of concrete:

concrete containing granular concrete material (RC-C), which contains recycled aggregate from demolished concrete components

concrete containing mixed granular material (RC-M), which also contains materials such as bricks and masonry

An RC-C concrete can have virtually the same properties as concrete made with natural aggregate (sand, gravel) but the concrete designated RC-M made with aggregate consisting of recycled mixed granular material exhibits greater differences.

The use of concrete containing recycled aggregate is linked to various preconditions. Not only must the clients and designers be able to trust the quality of this building material but the construction industry must also be willing to use concrete containing recycled aggregate. Incentive schemes, such as sustainability standards, are being formulated and normative principles and design aids are being worked out in Switzerland to achieve this objective and support clients, project leaders and designers in sustainable construction work. The safe application of concrete containing recycled aggregate in concrete construction is regulated by the technical code of practice MB SIA 2030 “Recyclingbeton”. This applies to the use of concrete granular material C (Figure 1) and mixed granular material M (Figure 2) for producing concrete containing recycled aggregate and concrete complying with the standard SN EN 206 [4]. It was published in 2010 by SIA, the Swiss Association of Engineers and Architects. The code of practice is aimed at designers, clients and authorities as well as at companies involved in demolition, processing and concrete production and at building contractors. In a concise form (16 pages) it lists the necessary definitions and the essential mechanical properties of concrete containing recycled aggregate as well as supplementary design principles.

The technical code of practice MB SIA 2030 “Recyclingbeton” is currently being revised to include important market developments, findings and changes from past years. The important additions and clarifications that are planned include:

2.1 New definition of concrete containing

recycled aggregate (Recyclingbeton)

The requirements for the constituents of concrete granular material C and mixed granular material M are being slightly modified.

For concrete containing recycled aggregate made with granular concrete material (RC-C) the aggregate now consists of at least 50 mass% granu-lar concrete material C. For concrete containing recycled aggregate made with mixed granular material (RC-M) the aggregate consists of at least 50 mass% mixed granular material M (cf. prMB SIA 2030, Table 1).

The use of aggregate “from the treatment” will now also be permitted for producing concrete containing recycled aggregate and concrete complying with the standard SN EN 206 (Table 1). This involves the cleaned constituents of a physically, chemically and/or thermally treated aggregate from processed excavation and demolition material as well as from excavated asphalt.

2.2 Verification of the proportions

of aggregate added

For concrete complying with SIA Code of Practice 2030 containing recycled aggregate the fine aggregates (particle size group 0/4) can be used, as before, for the production of structural concrete, except where there are special requirements, e.g. for durability.

For verification of the proportion of recycled aggregate the aggregate 8/Dmax is counted as described in SN EN 933-11 and it is assumed that the recycled particle size group 0/8 has the same composition as the counted recycled particle size group 8/Dmax if this comes from the same batch. The proportion of 50 % recycled aggregate can then be made up with the particle size group 0/Dmax. It is basically necessary to carry out a visual check and documentation of the recycled size group 0/8 for materials such as wood, gypsum, etc. The recycled particle size group 0/8 must not be used with higher proportions than the maximum permissible value defined in the code of practice.

2.3 Potential applications for concrete

containing recycled aggregate

Concrete containing recycled aggregate is basically treated and used as concrete complying with the standards SN EN 206 and SIA 262 [5] provided the code of practice does not contain any information to the contrary.

Only small quantities of concrete are used in civil engineering when compared with building construction and there is also little experience with concrete containing recycled aggregate concerning aspects that are relevant to durability, such as resistance to freeze-thaw with de-icing salt, chloride resistance, carbonation resistance and alkali-aggregate reaction. The new code of practice, like the old one from 2010, therefore restricts the use of concrete containing recycled aggregate to certain exposure classes. Potential use of concrete containing recycled aggregate RC-C is permitted in building construction as structural concrete for both internal walls (XC1, XC2) and external walls (XC3, XC4) and for floors. The lower elastic modulus and the greater creep deformation of concrete containing recycled aggregate have to be taken into account in the calculation of the deflection when RC-C concrete is used in floors between storeys. The design with concrete containing recycled aggregate is carried out in the same way as with concrete containing natural aggregate in accordance with SIA 262, which is based on Eurocode 2. Basically, the properties of the RC-M concrete (elastic modulus, shrinkage and creep) differ more sharply than those of the RC-C concrete from concrete containing natural aggregate. Use of RC-M concrete is therefore recommended in components where increased shrinkage and creep are not a problem. An RC-M concrete can be used for the exposure classes listed in Figure 1. RC-M concrete must not be used for prestressed concrete or components exposed to fatigue and RC-C concrete may only be used after appropriate preliminary investigations.

2.4 Classification of concrete containing recycled aggregate using elastic modulus classes

The precise composition of a concrete containing recycled aggregate, and in particular that of the recycled aggregate itself, is often not known before its production. Elastic modulus classes, which are based on the average and minimum elastic moduli (cf. prMB SIA 2030, Table 2), are listed in the code of practice to provide the designer with information about the elastic modulus. The concrete plants must determine the elastic moduli of the different types of concrete containing recycled aggregate to a defined extent both in the initial testing and also during the period covering the initial and continuous production.

Stringent quality assurance of the recycled aggregate along the production chain is essential to ensure the quality of concrete containing recycled aggregate, which is a comparatively very new construction material.

2.5 Possibility of defining additional requirements for sustainability properties

For concretes defined by properties, the sustainability properties may be stipulated as additional requirements in accordance with SN EN 206.

According to the draft of SIA MB 2030 these additional requirements in accordance with the standard SN EN 15804 [6] may be stipulated for parameters for describing the environmental effects and/or for parameters for describing the use of resources.

2.6 Shear force design and verification of punching shear for RC-M concretes

Based on extensive research work the shear force design and verification of punching shear can now be undertaken with defined design values when using RC-M concrete in floors.

3 Processed mixed granular material

as a main constituent in cement

Ecobalance studies [7] show that the use of concrete containing recycled aggregate is appropriate in Switzerland mainly because it removes the need to quarry gravel and because of the saving in landfill space.

As far CO2 emissions are concerned the ecological added value of concrete containing recycled aggregate over concrete made with natural aggregate (sand, gravel) is not automatically evident. Concrete made with crushed aggregate requires more cement than concrete made with the round, cubical aggregates typical of natural gravel. The balance depends mainly on the quantity and type of cement used and the lengths of the transport routes involved. The CO2 emission of concrete containing recycled aggregate can be lowered by using clinker-reduced cements. The reduction in the proportion of clinker in the cement is advanced significantly by the use of other main constituents.

The requirements for the composition of a cement are defined in the standard SN EN 197-1 [8]. According to this product standard the use of inorganic constituents, such as demolition materials, as main or secondary constituents is not permitted. However, publication of the technical code of practice MB SIA 2049 “Requirements for new cements” [9] in 2014 in Switzerland created opportunities to permit new cements using standardized and new constituents that are not covered by this product standard for normal cement (SN EN 197-1) for concrete complying with SN EN 206 (Table 2).

On the basis of this specific normative regulation in Switzerland, Holcim (Schweiz) AG developed a new cement using the fine fraction of the mixed granular material as a further main constituent. This cement is a certified CH Portland cement ZN/D 32,5 R in accordance with the code of practice SIA 2049 that consists of Portland cement clinker, high-grade, processed, mixed granular material and burnt shale. The mixed granular material is the fine fraction that is obtained during the industrial processing (wet or dry processing) of local mixed demolition waste and, because of its limited potential usage in structural concrete, has until now often been landfilled or used in inferior – so-called unclassified – concrete applications (Figure 3).

4 Results

The Portland cement ZN/D 32,5 R can be used in building construction ranging from simple concrete applications to the production of fair-face concrete and concrete for massive structural el-ements.

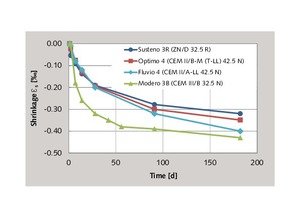

The concretes produced with this cement exhibit a moderate development of compressive strength (r value) (Figure 4) and low heat development (Figure 5), which substantially reduces the risk of temperature-induced stress cracks in the hardened concrete. The shrinkage of the concretes is very low when compared with concretes that are produced with other types of cement, such as limestone cement (CEM/II (A-LL)), Portland-composite cement (CEM II/B-M (T-LL)) and blastfurnace cements CEM III/B (Figure 6).

The sustainability potential of the concretes produced with this cement (especially concretes containing recycled aggregate) is very high because of the re-use of locally processed mixed granular material (Table 3). The Portland cement ZN/D 32,5 R exhibits only slight environmental effects and is unique in that it contains a very high proportion of secondary materials (mixed granular material).

//www.holcim.ch" target="_blank" >www.holcim.ch:www.holcim.ch

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.