A new point of view in cement plant operations

With the use of remote-controlled drones, cement producers now have a new tool to help increase productivity in daily operations, by providing faster and more accurate results in various applications that previously required skilled and expensive external service providers.

1 Introduction

Remote controlled planes and helicopters have been used for a long time by hobbyists and military forces, but only in recent years has progress in miniaturization of electronics, digital cameras and batteries allowed maximization of their full potential, making them accessible to everyone. Drones (also known as “UAV” – Unmanned Aerial Vehicle) are available in a wide range of type, size, performance and prices. The current technologies allow for live recording of photos and videos used in a wide variety of applications, including in the industrial world.

Holcim (US) Inc....

1 Introduction

Remote controlled planes and helicopters have been used for a long time by hobbyists and military forces, but only in recent years has progress in miniaturization of electronics, digital cameras and batteries allowed maximization of their full potential, making them accessible to everyone. Drones (also known as “UAV” – Unmanned Aerial Vehicle) are available in a wide range of type, size, performance and prices. The current technologies allow for live recording of photos and videos used in a wide variety of applications, including in the industrial world.

Holcim (US) Inc. Midlothian cement plant started using the drone’s advantages in a number of applications, including inventory and reserves estimation of stockpiles, monitoring of quarry blasts, inspections of elevated structures and plant aerial photography.

2 The Drone

Following an evaluation of the different types of drones on the market, Holcim decided to purchase a quadcopter from Leptron [1] equipped with a gyro-stabilized GoPro camera. Similar to a helicopter, but more compact due to the absence of a tail rotor, the drone allows hovering in steady position. The device is made of a carbon fiber structure ensuring proper strength and shock resistance while limiting the weight. It fits in a heavy-duty case as seen in Figure 1, ideal to carry on the field for quick deployment.

The drone offers a flight time between 15 to 20 min depending on the weather and flight conditions. This proved to be long enough for most applications while offering sufficient rest time for the operator. As far as performance is concerned, the four rotors provide sufficient power to fly in sustained wind up to 60 km/h, reach an altitude of 3000 m at a rate of 5 m/s and fly over 1.5 km at speeds up to 10 m/s. It the case of Holcim (US) Inc. only, the drone maximum altitude was limited to 120 m to comply with the FAA (Federal Aviation Administration) regulation in the USA [2].

The drone comes equipped with a GoPro Hero 3+ Black edition camera mounted on a 3-axis gyro-stabilized gimbal (Fig. 2). It records photos and videos in various modes depending on the situation requirements, and it can be upgraded with different optical lenses, for example to increase the zoom or remove the fish-eye effect. An option exists to add a thermal-imaging camera (Fluke type) in parallel of the GoPro.

The main feature of the quadcopter is its built-in autopilot and GPS systems which allow the drone the hover in position at a fixed altitude, thus compensating automatically for wind disturbances. The flight safety is ensured with three features: the smart mode, the return home function and the automatic landing: The first mode lays a virtual grid on the ground which allows the operator to move the drone in the direction of the grid independently from the drone orientation. It is particularly useful when the drone is far away and its orientation is unknown. The second function, when enabled, brings the drone back to the take-off site automatically by flying at a predefined altitude avoiding obstacles on the way. This function is activated automatically after loss of communication or by operator inputs. Finally, the automatic landing sequence is an emergency mode, activated when the drone runs out of battery to avoid a crash and potential damage.

3 Aplications in cement plants

In the past couple of months the team at Holcim Midlothian cement plant was able to use the drone in a number of applications across the facility including the quarry area. The drone proved to be a real asset for the monitoring and evaluation of blasts, especially with no elevated viewpoint. As seen in Figure 3, the quadcopter brings a new point of view above the quarry bench. With the help of the live video feed on the remote screen it is possible to set the drone anywhere in the sky above the blast line and unlike aerial photography from an airplane, the hovering capability of the drone guarantees a fixed image during the entire event. The capability of the GoPro to record in slow-motion (up to 120 or 240 frames per second depending on the quality) allows observation of the blasting sequence in orders of milliseconds to catch every action and detail of the blast. This proved to be a key tool to monitor and troubleshoot blasts, with the potential to improve blast efficiency and safety. Indeed the review of the blast in slow-motion highlighted fractures in the bench which influence the efficiency of the blast, dissipating some of the energy. The blasting sequence of the holes can also be checked and adjusted precisely based upon the video recording.

With regards to raw materials in the quarry and in the plant, aerial pictures taken with the drone can be used to calculate pile volumes using 3D mapping software. The current surveying method usually requires walking around the pile of material. It can be complicated and nearly impossible when dealing with piles of significant sizes, remote areas or material stored in sheds against walls. The drone provides a flexible way of surveying piles from any direction and any size. It is also the only safe method to see the peaks and hollows in the middle of the piles and obtain an accurate topography.

Figure 4 shows the resulting topography of a raw material pile processed using a video from the drone: the detailed elevation levels throughout the pile geometry provide a precise volume of the material.

In case the areas to be covered are too wide, the drone can be operated in automatic mode. The flight is programmed in detail via an iPad-based application which allows optimizing the flight pattern as seen in Figure 5. The operator can pause the flight and take over controls at any moment if needed. This is advantageous when surveying wide areas or doing 3D mapping where the overlap of pictures is important.

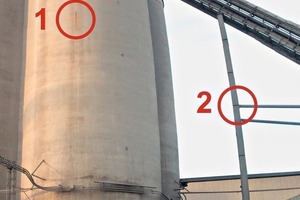

The added value of the drone is not limited to the quarry and stockpile measurement. Because it can fly anywhere above any structure in the plant, the drone can be used to conduct visual inspections of high-elevation buildings and structures in the plant and identify issues which would otherwise require scaffolding or cranes. The quality of the pictures is far better than what can be achieved from the ground level and the deployment of the drone is less risky, costly and time consuming compared to hiring specialized workforce for the task. Figure 6 shows a clinker silo where corrosion was spotted at about 25 m elevation. The detail shown in Figure 7 allowed better comprehension of the severity of the situation and assisted in the development of an action plan. Corrosion was also assessed on the bolted connections of steel structures (Fig. 8) and ductwork, including expansion joints.

Finally, the most obvious application of the drone is simply aerial photography. The quality of the pictures taken from the drone is much higher than satellite images available for free on the Internet. In addition, the pictures can be updated anytime and with the best weather condition, avoiding shaded areas as much as possible. This is an advantage to follow-up on a project or a site construction at any given point in time, but it can also help survey the property for environmental impacts or security matters.

Figure 9 shows the comparison of the plant aerial pictures available from Internet maps websites and the survey from the drone. The quality of the pictures from the GoPro, together with the flexibility to select the drone altitude, orientation and time of the day were very useful at the Midlothian plant. It proved beneficial in investigating layout possibilities during a major project engineering phase.

4 Regulations and next steps

There have been many concerns in recent years about the growing number of drones flying in the sky, especially in cities and over public places. Regulation is being developed in different countries to define proper boundaries and requirements for the safe use of these tools. Based on the existing experience from the hobbyist world as well as proposals from aviation agencies such as the FAA in the US [2], we can expect that the use of drones will be possible for civilians and professionals with some restrictions. Preliminary indications suggest having trained operators (including drone and air space know-how) and flying above private/business properties only.

The drone must remain in the lowest air space (class G shown in Fig. 10) at a maximum altitude below ~ 150 m (400 ft. in the US) or below the cloud line. Eventually visual contact, communication and control of the drone must be ensured at all times.

Such requirements are currently in place in Holcim (US) Inc. Midlothian plant and are certainly not limiting factors to using drones as a key component in a cement plant’s toolbox.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.