Digital delivery note with pen and paper

Customers benefit greatly from a new digital delivery note system and internal operating and administration costs have decreased enormously.

Over 200 000 delivery notes per year

Anke Adler, the IT manager at maxit Baustoffwerke GmbH, said “Up until now, whenever customers have rung up to enquire about their delivery, we’ve not been able to give them any information. We’ve had to try and contact the driver by phone and ask him to fax the delivery note. That was terribly expensive and customers were dissatisfied.” Each day, maxit was faced with needing to get back about 700 delivery notes with customer signatures from drivers promptly so that they could be archived, and recorded centrally on its computer system at its Krölpa plant so that the orders could be passed on to its billing department. The following major problems demanded an innovative solution:

The period between a delivery note arriving at a customer’s premises and reaching Krölpa for the final processing stage could last as long as three weeks.

Maxit was often unable to provide customers with any information if they had a query about a delivery, because the relevant delivery document had not yet been returned and was still in the delivery lorry.

Delivery notes sometimes got lost.

The hard copy archive was huge and took up an unbelievable amount of room (because of the ten-year legal retention period). It had become unmanageable and older delivery notes could no longer be found again.

The dot matrix printers used as part of the old system were expensive to run and maintain.

Writing and digitalising at the same time

Putting the solution into practice

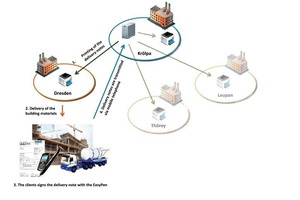

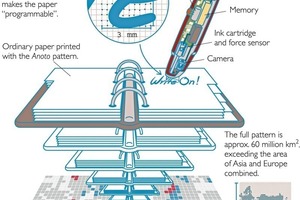

Mr Schüßler added, “In our first meeting, I quickly realised that implementing the right solution in a way that would allow business to continue as smoothly as possible without being disrupted or interrupted would almost be more important to maxit than finding the solution itself.” Communication between the merchandise management system (IBM System I5) and the Ontaris EasyPen server, which are both at the Krölpa plant, form the spine of the solution. As before, the delivery notes are produced by the IBM System I5. Instead of printing them out straight away, however, the IBM system forwards the information to the EasyPen server. Here, delivery notes are either given an individual background pattern, which is compatible with the EasyPen, or have a unique barcode allocated and added to them. Delivery notes are printed using standard four-colour laser printers. All five sites are connected, and each delivery note is automatically dispensed by the printer assigned to the site supplying the respective goods.

It is necessary to add barcodes to some of the delivery notes, because not all of maxit’s subcontractors use the EasyPen. A way of uploading signed delivery notes to the document management system automatically had to be found in spite of this, and so barcodes were introduced. These contain the delivery note number and the customer number, which allow the delivery note to be digitalised automatically by a scanner and uploaded to the document management system.

In the morning, drivers now take the delivery notes required for their day’s schedule as usual, but when goods arrive at a building site, the customer confirms the delivery by signing the delivery note with the EasyPen. Customer comments can be recorded as well. These are then transmitted to the head office with the invoice via the driver’s mobile phone. The delivery note remains at the building site as proof for the customer, but by the time the driver leaves, maxit already has a digital PDF copy of the information. In addition, the advisor responsible for the order receives an email with the completed delivery note, which can then be processed further and used to issue an invoice.

Improved service and lower costs

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.