Whether being used as building material for houses and staircases, for streets, tunnels and bridges or impressive dam walls – concrete is omnipresent in the modern construction industry and thus in the overall infrastructure of the industrial nations. Completed constructions are literally held together by a key component of concrete: the binding agent cement.

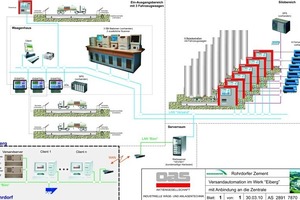

In the year of 2010, about 22 companies produced about 29.9 million t of this mass product in 54 factories throughout Germany. The Portland Cement Plant of the Rohrdorfer Group, situated in the South of Rosenheim (Fig. 1), moves about 15 000 t of material (Fig. 2) each production day, including about 5000 t of cement. Since 1930 the Group has been producing customised cement mixtures as well as standard products for the construction of tunnels, civil engineering and specialist foundation engineering at their plant located in the South of Bavaria. To ensure that each customer gets exactly the right mixture for his construction project, the Rohrdorfer plant provides more than 16 loading and 10 unloading stations, 11 truck scales and a mixing tower.

Availability around the clock

In order to permanently provide its customers with high-quality building material at competitive prices, the company decided to extensively automise all dispatch transactions between all single parts of the plant, and thus improve the availability and the efficiency of the complete plant. Apart from the internal flow of goods, the goods receipt, as well as the outgoing goods, have also been integrated into the comprehensive logistic solution. The demands of the Rohrdorfer group: The entire variety of logistic processes starting with incoming goods up to dispatch transactions should be managed and controlled continuously by a single process control system combined with reduced operations costs and a 24/7 plant access. Moreover, the truck drivers should be able to carry out all required operation procedures (Fig. 3) independently on-site in order to increase the process velocity and to avoid operational errors.

The Rohrdorfer Group decided to choose OAS AG from Bremen as partner for the automation project. The specialists for weighing technology and automation offered an extensive, one-stop solution including its own software applications Logis Enterprise and Pronto, automated truck scales and self-service terminals. „We have checked different providers,“ head of IT Günter Hefter says. „OAS AG proved to be the perfect partner, because its employees provide the necessary know-how in all required areas.“

Interface to the ERP system

Practically, the plant logistic solution Logis Enterprise is the backbone of the complete automation solution (Fig. 4). Orders can be registered in Logis even prior to the trucks’ plant access. The software is designed to handle all relevant kinds of transaction types such as standard sales orders, third-party orders or non-invoiced orders as well as stock transfers to separate sites. Moreover, the software functions as a central interface to the ERP and the financial system SAP for the electronic data exchange of master and order data.

Based on the software, Rohrdorfer Zement realised a central order management system which registers and controls all material flows on the plant site. One further advantage of the software solution: For goods receipt, Logis also supports handling of hazardous materials with special safety criteria. With the help of electronic data exchange, delivery notes and records of proper waste management are available plant-wide at any time. Thus, all incoming and outgoing goods may be supervised continuously and without interruption. “In the past, working in a dispatch office was like working at the railway station,” Rohrdorfer dispatcher Michael Straßer summarizes. “Today, we hardly notice the numerous transactions at the company premises.”

Terminals for different tasks

Around 30 OAS self-service terminals interface to the automation hardware – the truck scales. The terminals are installed at strategically important places on-site e.g. the plant entrance, the weighing stations, conveyor belts or loading stations. The hardware equipment of the terminals depends on the requirements and determines the work steps to be carried out by the driver. For various application purposes, different standard terminals are available – from simple identification panels via loading panels with integrated control functionality to touch screen panels equipped with laser printer and an electronic functionality to capture the driver’s signature on-site and then to print out the shipping documents.

Order data just-in-time

To identify the truck drivers on-site, Rohrdorfer Zement decided to use bar codes which are reasonable and efficient for this purpose. Barcodes can easily, quickly and cost-efficiently be printed out from each printer and be transmitted via the internal network or via the internet. The documents’ barcodes are read out by high-quality, omnidirectional barcode scanners in the OAS terminals at the plant entrance thus authenticating the truck drivers. The dedicated order data are displayed at the terminal immediately and the appropriate transaction sequence starts. In case of non-regular forwarding agencies being in charge of material transports, a valid transaction can be created just-in-time when the driver contacts the plant entrance panels. In case of functional disorder or any problems with the self-operated dispatch transaction, the drivers can contact a dispatcher to assist them by the help of an integrated telephone. “So the drivers know that the dispatchers are just a push of the button away and always available,” Michael Straßer says. “Moreover, it is very important for a smooth procedure that all loading and unloading stations offer identical self-service panels and standardised transactions for the drivers.”

Mix and load automatically

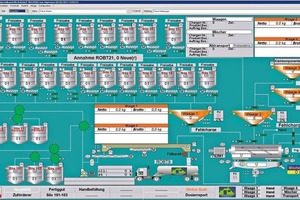

The execution of all orders on time is guaranteed by several cement mixing plants which are controlled by the OAS control system Pronto (Fig. 5). The control system also includes functionalities for the clearance of the batch and Supervisory Control and Data Acquisition (SCADA). In case an order requires a customised mixture, the control system of the mixing plant switches the order queue just-in-time giving priority to the driver’s transaction immediately after the driver has registered and has been identified at the mixing tower.

Right after the transaction has been finished, the mixing plant’s control system order queue falls back into the original production order sequence. After the final weighing on the OAS truck scale, the driver receives the delivery note and the related documents at the self-service terminal and is able to leave the plant.

Conclusions

Right after the successful testing phase of the comprehensive automation structure, Rohrdorfer Zement has implemented further small plants with single truck scales and a few loading stations in cooperation with OAS AG. Afterwards, independent, medium-sized production facilities at other locations have followed. By the help of the centralised software application, the operator is able to supervise and control the entire process across several plants. Thanks to the extensive standardised system, Rohrdorfer Zement has significantly reduced the operational costs and provided a 24/7 customer plant access. As a result to the positive experience with the OAS solution, the producer of cement has implemented the system in another major cement production plants in Austria – including several close-by locations. “After the successful commissioning in Germany and our strong bond of trust in OAS AG, we have been able to extend the implementation of the software-hardware-combination to our Austrian location without any concerns,” Rohrdorfer sales manager Gerhard Godl says.