Higher economic efficiency after modernisation

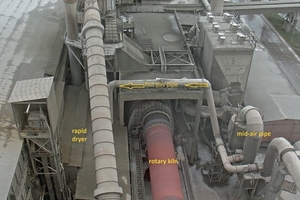

The object here is to improve the productivity and profitability by making cost-effective investments in an existing system. Because optimization activities were done at the Ünye Cement Plant, all examples given are from this plant (Fig. 1). Having completed pre-calcination investments in 2002, Unye cement production plant has realized many optimizations up to the present. In the following article, some of the work that has been performed at the cement mill unit is described in detail along with the reasons and calculations:

Inclusion of hot air from rotary kiln to rapid additive dryer in...

The object here is to improve the productivity and profitability by making cost-effective investments in an existing system. Because optimization activities were done at the Ünye Cement Plant, all examples given are from this plant (Fig. 1). Having completed pre-calcination investments in 2002, Unye cement production plant has realized many optimizations up to the present. In the following article, some of the work that has been performed at the cement mill unit is described in detail along with the reasons and calculations:

Inclusion of hot air from rotary kiln to rapid additive dryer in 2006,

Improvement of the productivity of the separator of the 3rd Cement Mill in 2007,

Capacity enhancement of big-bag filling facilities in 2008,

Capacity enhancement of 3rd cement mill in 2009.

1 History of Unye Cement

Unye Cement Industry and Trade Inc. was established on May 28, 1969 in Unye, in the borough of Ordu to produce cement. The partnership that was established consisted of the Turkish Cement Industries holding 40 % of the shares, the Armed Forces Pension Fund (OYAK) 40 % and other individuals with the remaining 20 %; with a capital of 1 million TL started its activities and the first cement was produced on May 27, 1974. The establishment capacity of the factory was 600 000 t/a. With the various capacity increases, rehabilitation and modernisation works executed at different times as of the establishment the capacity reached its present volume: 1.5 million t/a fabricated clinker and 2.6 million t/a cement.

In 1990 it was invested in a high-pressure grinding roll (POLYCOM) from Polysius and high efficiency seperator (SEPOL) from Polysius. In 1999 a third cement mill was added by the Russians. In 2001, the upgrade of the rotary kiln by KHD (pre-calcination system, new raw mill from Gebr. Pfeiffer AG, new crusher from Hazemag, pre-blending) was scheduled. 2007 the third cement mill and roller press was upgraded by KHD.

Unye Cement produces various types of cement in conformity with the TSE standards that have the EC conformity document. For three different types of cement this prerequisite for exportation to EU countries is valid:

Cem I 42,5 R,

Cem II/ A-M (P-LL) 42,5 R,

Cem V/ A (S-P) 32,5 R,

The company executes sales from three points:

The main facility: Alongside the administrative activities there is capacity to produce 1.5 million t of clinker and 2.6 million t of cement at these facilities situated at Ünye. A great amount of the domestic sales and exports are carried out from this facility and the Unye cement port, 2 km away from the factory and with the right of prior use for 49 years.

Rize Çayeli terminal: The packing facility that started operation in 1998 sells bulk and bagged cement to the East Black Sea Region.

Romania terminal: This stocking and packing terminal started operations in the first quarter of 2009 at the Mangalia Port to sell bulk and bagged cement to the developing Romanian market and Bulgarian market whose border is only 6 km away. The company, Unye Cem SRL was established in 2007 according to the Romanian law.

The ready mixed concrete facilities were transferred to affiliate OYAK Concrete Inc. in 2004 as capital in kind. Unye Cement Industry and Trade shares have been traded in the ISE since May 11, 1990 with the symbol UNYEC. The company has become the Tax Record Holder in the city of Ordu in 2007 and ranks among the 30th most profitable companies among the 500 Industrial Blue Chips of Turkey in 2007.

The following standards are considered at Unye Cement:

TS EN ISO 9001:2000 Quality Management System,

TS EN ISO 14001 Environment Management System,

OHSAS 18001 Labour Health and Safety Management System.

Unye Cement has set up the ‘Integrated Management System’ by uniting the Quality Management System, the Environment Management System and the Labour Health and Safety Management System.

2 Improvement measures

2.1 Inclusion of hot air to the rapid additive dryer (R.A.D.)

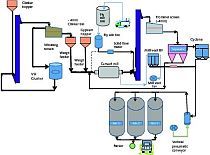

Pozzolana (trass) and slags used in the production of blended cement (Fig. 2) have an average humidity of 11–14 %. In order to decrease this rate to a level of 4–6 %, rapid additive dryer is used. Hot air in the rapid additive dryer is produced by burning fuel oil. Hot air is then forced into contact with the wet materials so that heat transfer is provided and humidity is decreased to the level of 4–6 %. Approximately 576 kg/h fuel oil is used for the drying process. Given that the annual average operating hours of a rapid additive dryer are 2.660, approximately 1532 tones of fuel oil is used annually. The optimization that is made is that the residual hot air obtained from the rotary kiln was conveyed to the rapid additive dryer through a pipe and drying process was maintained by this hot air. Table 1 shows the calculation of heat consumption and flow rate required for this project. The investment costs are about 60 000 US$, the amortization period is merely 8.9 days and the approx. saving from avoiding the use of fuel oil is about 927 366 US$/year.

2.2 3rd cement mill separator productivity enhancements

In 2007, within the scope of the 3rd investment for the cement mill roller press and V-separator, the 1st generation existing Russian modified separator was replaced with a 3rd generation (SKS) separator from KHD. The yielded capacity after the change dropped by about 12 %. Fine properties of the samples taken after the change were analyzed in detail. According to the results of this analysis, the products with desired fineness were returned to the mill through feedback and as such the separator did not work properly. When the process was examined, it was found that the separator has five separate feeding inlets, but the whole product was passing through the last inlet. Due to the fact that feeding was done through only one inlet the required air flow rate could not be provided. Consequently when the products were fed as a batch to the separator, the separating process could not be done by the separator. The realized optimization to provide even feeding to all five inlets was to place directing plates in particular lengths at each chute. Sieve analysis values related to the fineness are shown in Figures 3 and 4. The numerical data are given in Table 2. The respective calculations are provided in Table 3. By these measures the capacity of the mill has been increased from 79 t/h to 97.6 t/h. Capacity has increased by 23.5 % and the corresponding energy value has decreased by 6 kW/t. The saving from grinding energy consumption: 114 921 US$/year.

3 Capacity enhancement of big-bag filling facilities

Capacities of the big-bag production stations were improved by program optimization and by using a bigger rotation reducer in order to increase rotation of helix cycles. With the help of a belt-pulley system, the helix capacity was improved by changing the pulley diameter and strengthening the engine reducer afterwards. Eventually 4 big-bag stations capacities were increased from 18 t/h to 25 t/ h. The realized capacity enhancement was about 38 % at 5333 $ investment costs.

4 Capacity improvement of 3rd cement mill

Samples were taken at the pneumatic conveyor lines located between the cement mill and roller press. Sample analysis showed that the product with ultimate fineness was fed to the mill. In the analysis of 45 micron under-sieve residual product, it has been determined with the calculations that 3rd generation separator (SKS) of the mill can make this separation process. Realized optimization; by connecting the mill feeding line directly to the separator, about 11.9 % capacity enhancement was obtained and grinding energy consumption was decreased by 7.1 %. Table 4 shows the fineness values as well as the capacity changes by cement type.

In the proportional energy calculations, energy consumption has decreased from 39.2 kW/t cement to 36.4 kW/t cement. The investment costs are 1333 $, the return duration is about 3.4 days. The saving from grinding energy consumption: 143 360 $.

5 Conclusion

In total all the modifications have led to a saving of about 1,2 million US$ (Table 5).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.