Sampling free on-line analysis in air slides

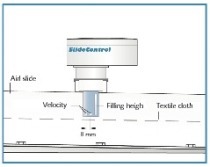

SpectraFlow using SOLBASTM technology now permits the analysis of raw meal from the raw mill in air slides, without sampling stations and XRF analysis in the laboratory. The system is designed to use the available control openings in the air slide and is a viable alternative to the standard automatic sampling systems for process optimization.

Once the material for the cement making process has passed the raw mill, its standard means of transportation is normally the air slide. From then on samplers are used to get the material out of process flow and the samples are transported to the laboratory for XRF analysis. Today very elaborate solutions exist for the automatic sampling, homogenizing of the samples, transport of the sample and its analysis by XRF. They can make batch sample analysis results available at rather short intervals, which, if the control software takes proper care of the time gaps between the samples, can be used...

Once the material for the cement making process has passed the raw mill, its standard means of transportation is normally the air slide. From then on samplers are used to get the material out of process flow and the samples are transported to the laboratory for XRF analysis. Today very elaborate solutions exist for the automatic sampling, homogenizing of the samples, transport of the sample and its analysis by XRF. They can make batch sample analysis results available at rather short intervals, which, if the control software takes proper care of the time gaps between the samples, can be used to control the raw meal to a target chemical composition. However they require elaborate mechanical systems which tend to require elaborate maintenance and the batch character of the sampling cannot be overcome.

SOLBASTM technology, which is the extension of Near Infra Red (NIR) analysis to minerals, offers an attractive alternative for on-line analysis in air slides. The scanning rate is so high, that it provides quasi-continuous measurement values. It does not need sampling and it uses existing maintenance openings on the air slide.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.