Expert system for optimization of cement mills

Summary: The milling process in cement plants is extremely energy-intensive, accounting for nearly 45 % of the overall electrical energy requirements. Siemens has designed an expert system which uses actual plant data to make precise predictions about quality parameters for a production plant, and which can be integrated into the existing PCS-7 control system with no additional hardware. Mill control can be optimized on the basis of predicted quality parameters, which in turn reduces energy consumption and has a positive influence on the plant’s cost-effectiveness and availability, as well as on product quality. The first pilot project was conducted at the Südbayerische Portland-Zementwerk in Rohrdorf.

1 Portland cement production in Rohrdorf

At the Südbayerische Portland-Zementwerk in Rohrdorf, the raw materials extracted from the neighboring quarries that are necessary for producing Portland cement clinker are stored in a blending bed hall and then ground into raw meal in a raw mill. In the rotary kiln the raw meal is then burnt to cement clinker, which is the basic material for all types of cement. The plant has four ball mills for a total output of around 270 t/h. Grinding is performed in a ball mill with steel balls of different sizes. Depending on the type of cement, materials such as...

1 Portland cement production in Rohrdorf

At the Südbayerische Portland-Zementwerk in Rohrdorf, the raw materials extracted from the neighboring quarries that are necessary for producing Portland cement clinker are stored in a blending bed hall and then ground into raw meal in a raw mill. In the rotary kiln the raw meal is then burnt to cement clinker, which is the basic material for all types of cement. The plant has four ball mills for a total output of around 270 t/h. Grinding is performed in a ball mill with steel balls of different sizes. Depending on the type of cement, materials such as blastfurnace slag can also be added to the milling process. The grinding media moves differently, depending on the mill’s speed. At low speeds, a cascading movement is produced in which the balls simply roll off. As speed increases, the balls are lifted and fall onto the grinding material (cataracting movement). Above a “critical” speed, the balls are held fast to the drum walls by centrifugal force and almost no grinding occurs. The best operating point is above the point where the cataracting movement begins and below the critical speed.

2 Requirements facing an optimized ball mill control system

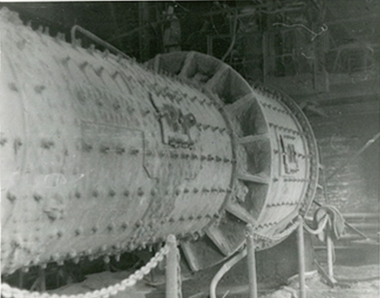

Siemens has developed a new mill control system to optimize mill energy consumption. The first pilot project involved one of four ball mills from 1965 belonging to the Rohrdorf Zementwerk. This mill has two chambers: the first chamber is filled with large steel balls and the second with smaller balls. The ball mill is 11.57 m long, with a diameter of 3.80 m and a rotational speed of 15.4 rpm. The drive power is 2400 kW and the mill output is 60 t/h (Fig. 1).

One of the most important quality parameters in cement milling is product fineness, which is analyzed in laboratories. Samples are taken on an hourly basis and the results are used for process correction. Sensors (acoustic ears) register the mill’s filling level (Fig. 2). The new control system was to record and adapt the quality parameters automatically. A further challenge was the removal of the old optimization system and integration of the new system in the existing PCS 7 environment at minimal cost. This required software that could assess quality parameters for the production plant using a knowledge-based approach dependent on current plant data (defined measured variables). This expert system was to regulate the control variables automatically and thus reduce the workload for operating personnel. An additional goal was to achieve maximum throughput at the desired fineness of grind.

3 System architecture and implementation of the new ball mill control system

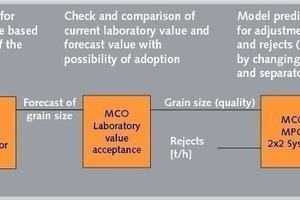

To meet these requirements, Sicement IT MCO (Mill Control Optimization) uses components from the APC (Advanced Process Control) library of Simatic PCS 7, by means of which even complex relationships between process parameters and variables can be mathematically described and used for automatic, flexible plant operation. A neuronal soft sensor collects the process input variables and predicts fineness. To reduce process fluctuations and stabilize the grinding process, a model-based predictive control (MPC) is used that has a complete model of process dynamics with all the connections. The combination of the neuronal soft sensor and the MPC system is specially suited to the complex nature of the milling process.

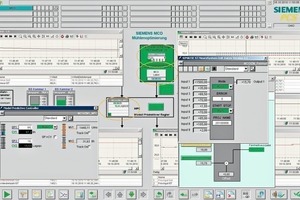

The MCO system was implemented in three phases: Firstly, the cement mill’s system status was analyzed. This involved identifying the existing input and output variables and assessing the quality of existing control solutions. In the second phase, system tests were performed to determine the step responses and record the production data. After the data had been evaluated, product-specific identification tools were used to develop a model of the neuronal soft sensor and MPC system. The third phase involved the software engineering for integrating Sicement IT MCO into the existing Siemens PCS-7 control system (Fig. 3). This could be done while the plant was in operation because the new control system initially ran only in the background, without directly affecting current operation. Once the new control system was ready to take over all the functions, the old system was deactivated. To permit optimal use of the new system, it was then reworked based on the previously defined production data from up to eight recipe types.

4 Operating principle of the optimized ball mill control system

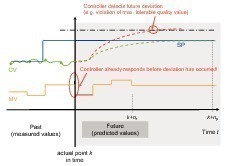

The new mill control system works in three stages: First, the neuronal soft sensor registers a total of nine process input variables from which it generates a prediction of fineness. These process variables include separator speed, quantity of fresh material, position of the swirl control valve, and representations of the mill’s filling level (circulating bucket elevator power, mill drive output, electric ear chambers 1 and 2) as well as the mill temperature and selected recipe type. The predicted fineness is then compared to the laboratory values as a position parameter. The aligned values for fineness (quality) and the measured grit (return material) are the MPC’s control values. By modifying the quantity of fresh material and separator speed, these values are optimized. This is accomplished through the predictive calculation of corresponding control processes based on a complete process model, in order to align the control variables as closely as possible with the desired set point values. In other words, external set points are determined for the individual subordinate controllers in order to optimize future plant performance over a certain period of time (Fig. 4).

5 Results of the optimized ball mill control system

Because the MCO system determines the set point values for the individual controllers, it is possible to ensure optimal production and quality results and to guarantee stable production conditions that are at all times aligned with current mill conditions. This makes it possible to significantly reduce the length of time formerly taken for a change made at the system input to evoke a corresponding response at the system output within the controlled system. The more uniform milling process thus achieved serves to optimize the mill’s throughput while maintaining the desired quality and reducing the workload of the operating personnel. It is possible to reduce energy consumption per ton of cement and extend the life of the plant’s mechanical systems. Compared to operation without an expert system, Sicement IT MCO improved plant performance by 5 to 8 % (Fig. 5).

In contrast to the old control system that relied only on the Blaine value as a measured variable, Sicement IT MCO controls plant operation also on the basis of the quality parameter (measured as so called “Lageparameter”) and permits external access to quality and production data. This renders data comparable and makes further optimizations easy to implement. Unlike other new systems, Sicement IT MCO can also be fully integrated into the plant or the existing PCS-7 control system without incurring additional maintenance costs for plant operators.

After the mill control system had been successfully optimized for the first ball mill, Siemens began optimizing the second mill. The other two mills will follow suit.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.