Process optimisation specifically for the cement industry

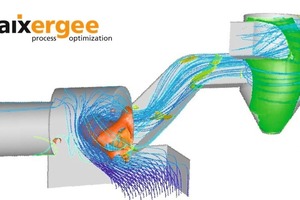

By joining the expertise of the companies 3e consult and aixprocess, both from Aachen/Germany, a new service provider for the international cement industry has been formed: aixergee offers support and solutions for all questions related to the optimisation of processes for the production of cement. Through a unique combination of cement experience and competence in process engineering and numerical methods (Fig.) , even most difficult objectives like e. g. the combustion of lumpy secondary fuels or the injection of oxygen into kiln flames can be investigated and the applied technology can be...

By joining the expertise of the companies 3e consult and aixprocess, both from Aachen/Germany, a new service provider for the international cement industry has been formed: aixergee offers support and solutions for all questions related to the optimisation of processes for the production of cement. Through a unique combination of cement experience and competence in process engineering and numerical methods (Fig.) , even most difficult objectives like e. g. the combustion of lumpy secondary fuels or the injection of oxygen into kiln flames can be investigated and the applied technology can be designed optimally. aixergee has a set of models at it’s disposal, developed specifically for the cement industry, tested and trued in numerous cases, to investigate all burning issues of the industry like for instance SNCR-processes, flows through filters, combustion of several types of fuels, calcination and sintering processes, separation and sifting processes and many more.

aixergee is headed by Dr. Martin Weng and Matthias Mersmann, who combined their experiences in process modelling and computation, cement plant equipment and operation. “The lesson learned from many optimisation projects is that neither experience nor sophisticated yet unspecific CFD knowledge alone lead to success. The complex cement production processes of today require the joint approach of industry-related experience and science-oriented methods to achieve further improvement” says Matthias Mersmann, who spent 14 years with KHD Humboldt Wedag, where he headed the departments for process engineering, design and automation and was responsible for R&D. “The cement process poses specific requirements to modelling and computation which can not be fulfilled by standard software codes. Therefore we have developed specialised tools for the cement industry” says Dr. Martin Weng who has written his Ph.D.-thesis on cyclone flows. Drawing on a team of 10 experienced and well educated engineers, aixergee offers not only CFD-computations but the full spectrum of services for all efficiency-relevant aspects of the cement production like e. g. plant assessments, site-services, optimisation of the plant operation, process engineering and staff training. “In hard times like today’s, process optimisation is of paramount importance and it will remain to be on top of the agenda in the future. We do not consider ourselves to run in competition to the specialists of our clients but rather as meaningful supplements to open up new possibilities for the cement industry.”

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.