Working together safely – VDZ working group “Occupational Safety”

For almost 60 years, the Verein Deutscher Zementwerke e.V. (VDZ), the German Cement Works Association, has been supporting German cement plants on the subject of occupational safety by means of a working group that meets on a regular basis. After a section summarizing the history of the “Occupational Safety” working group, this article presents the topics currently being dealt with and the working group’s cooperation with other bodies, as well as the occupational safety competition which is organized annually by the VDZ.

1 Introduction

Work in the complex production plants of the cement industry is associated with a multitude of potential hazards. For this reason, occupational safety work in cement plants is enormously important. The topic of occupational safety always comes first in daily meetings and is actively integrated into the daily work routine at many points in the process. For almost 60 years now, the VDZ has been accompanying occupational safety in German cement plants by means of a regularly-convening working group. Twice a year, safety experts from the plants meet with representatives of the...

1 Introduction

Work in the complex production plants of the cement industry is associated with a multitude of potential hazards. For this reason, occupational safety work in cement plants is enormously important. The topic of occupational safety always comes first in daily meetings and is actively integrated into the daily work routine at many points in the process. For almost 60 years now, the VDZ has been accompanying occupational safety in German cement plants by means of a regularly-convening working group. Twice a year, safety experts from the plants meet with representatives of the employers’ liability insurance association and the VDZ. This provides an impressive demonstration of the way good and effective cooperation works in the interests of the well-being of all employees – those of the cement plants themselves and those of external companies.

2 Safety work with a long tradition

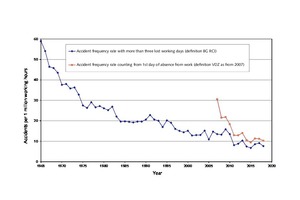

After initial analyses of the occupational accidents occurring between 1955 and 1958, the VDZ committee “People at Work” decided in April 1959 to establish the “Accident Prevention” working group (the title was changed to “Occupational Safety” in 1970). The remit of the working group was to perform the tasks of compiling accident prevention regulations, identifying the causes of accidents, developing recommendations for the prevention of accidents and keeping accident statistics. It was also mentioned in the founding resolution that cooperation with the employers’ liability insurance association was desirable for achieving the objectives of the working group. In the following years, the working group first examined the incidence of accidents by recording the type of accident, the time of the accident and the nature of the resulting injuries. Starting in 1963, the accident statistics were directed to the still continuing documentation of the frequency of accidents. Table 1 shows the representation of 1969 results in comparison to those of previous years, Table 2 shows the evaluation of the current reporting year 2018. Since the 1960s, occupational safety has continued to evolve. In line with this development, the accident frequency rate has dropped significantly over the past decades. Figure 1 shows the trend of notifiable accidents involving more than three lost working days for every 1 million hours worked from 1965 to 2018. Since 2007, in addition to the notifiable accidents according to the rules of the German Employers’ Liability Insurance Association with three or more working days lost, all accidents involving more than one day of absence are recorded. This corresponds to the international standard definition of “Lost Time Incidents (LTIs)”.

However, the VDZ working group on occupational safety has not only dealt with statistical evaluations, but in particular with the variety of often recurring questions concerning operational practice. These have included such organizational topics as the use of premiums to improve occupational safety, how to deal with individual workplaces that entail a high exposure to risk, and the recording of near accidents. In the 1990s, risk analysis and risk assessments were increasingly addressed, as were the handling of alternative fuels and raw materials. A large increase in eye injuries in the late 1990s led to a gradual introduction of the compulsory wearing of protective goggles, which is general practice today. Over the years, the working group concerned itself with this process, as well as many other topics.

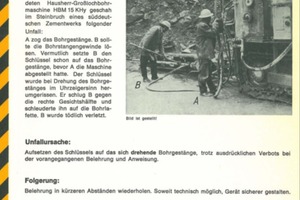

One core element of every session was, and still is, the analysis of the current accident situation. To this end, the members of the working group report on accidents at their own plants as well as on relevant events in the entire sector of the pit and quarry industry. The causes of accidents and possibilities for their avoidance are analyzed. If new hazards occur or if an accumulation of accidents in certain areas becomes apparent, the working group can react directly. One important instrument here is the safety bulletin, which appears three times a year as a supplement to the VDZ newsletter. Since 1972, this has described noteworthy accidents and given details of their causes and the consequences derived from them. Starting in 1979, the bulletins have been published together with a safety checklist that can be used directly at the production line. Figure 2 shows the first bulletin and the first checklist. In May 2019, bulletin No. 139 on the safe handling of components and deposits containing chrome was published together with a corresponding checklist. Currently, the working group is also for the first time discussing ways of transferring the classic bulletins into a new, digital format, which will enable faster and more targeted communication of accidents and suitable protection measures to the relevant employee groups.

In addition to these regular publications, numerous other documents have been developed by the working group and various task groups. For example, in 2002 training material was published for an accident training course, including topics such as tyre fires in the open-air storage facility or CO2 alarm in the electrical equipment room. As from 2005, the handling of hot meal was increasingly on the agenda. After a symposium on “Working safely in hot areas of cement plants”, the VDZ code of practice Vt 12 was published in 2011, with more than 70 pages documenting “Health and safety in hot areas of cement plants”. At the same time, a recommendation for action regarding the application of the Machinery Directive (2006/42 EC) was developed, explaining with practical examples how to implement the complex set of rules. This was later supplemented with aspects of functional safety. In addition, a guideline for testing in accordance with the Industrial Safety Regulation was published in 2011 in the form of a comprehensive Excel-based safety testing matrix.

3 Current topics

In the last two years, the working group has dealt intensively with the handling of components and deposits containing chrome in the area of the kiln system. Increasing use of high-alloy steels in the clinker burning process zone (e.g. anchors and dip tubes) leads to the formation of chromate (chromium (VI) compounds). This cannot be prevented by process technological measures. A recommendation for action was developed to sensitize the affected groups of persons and also to facilitate the identification of affected areas and show possible solutions for safe working in areas exposed to the problem. This particularly focussed on maintenance and repair work on the high-alloyed components that are typically encountered in the clinker burning process, as well as on deposits occurring in the vicinity of these components (kiln and preheater). Particularly of relevance in this connection is work carried out during plant standstills, such as refractory work, replacement of metal parts or stripping work. Figure 3 shows an example of the typical chromatic yellowing at the kiln outlet. It should be noted that the yellow discoloration sometimes only becomes visible some days after the kiln plant was shut down. For this reason, sampling and verification by means of a rapid test is recommended in case of doubt. The recommendation for action provides concrete information on this as well as on chemical reduction, protective measures when working in chromate-hazard areas and on storage and disposal. The document is supplemented by an Excel spreadsheet with examples of suitable personal protective equipment for activities in risk areas. Both documents are available on the VDZ website in German and English.

The personal protective equipment (PPE) to be used in the hot zone is still one of the topics of constant relevance. The comfort of modern, ventilated helmet systems has significantly improved the acceptance of sealed protection solutions. Through a series of tests with hot meal and through tests with personnel wearing PPE in the plants, weaknesses were identified and the compatibility between different systems was improved. But aside from practical or formal questions, the “safety culture” and interactions with employees in the plants are currently the focus of discussion. Influencing personal behavior is the biggest challenge in occupational safety and always requires new approaches. All those affected must not only be instructed in a legally certain context but also regularly motivated. Only in this way can it be ensured that occupational safety is really consciously lived and that the dangerous “getting into a routine” can be prevented again and again. At the same time, it is no longer just one company’s own employees that have to be considered. Dealings with outside companies are an essential part of the safety work. An effective consequence management is among the measures required in order to ensure the safety of all persons on the factory premises. This must already be assured through appropriate clauses in the contracts concluded with every outside company.

4 VDZ occupational safety competition

For many years now, the VDZ occupational safety competition has been an important motivation tool. Once a year, the plants with the lowest accident frequency rates are awarded a prize. The prize is awarded in two categories to plants with clinker production and to the much smaller grinding plants without clinker production. Since 2007, the accident frequency assessment has been based on the already explained definition of LTIs – i.e. accidents in which the injured person cannot return to full or reduced work in the next shift (CSI 2013). Despite the introduction of this tightened criterion, over the last 10 years the number of accident-free plants awarded certificates and the coveted gold plaques has regularly been above 20. These awards are prominently featured in many German plants, e.g. in canteens and entrance areas. In this way, employees are sustainably motivated to maintain good safety work. Because nothing is more difficult – and all winners acknowledge this – than repeating a very good result year after year. Figure 4

shows the proud winners in 2018.

In a constantly changing working world, it has to be ensured that such a competition is based on up-to-date criteria. For this reason, the work safety group regularly reviews the rules and results. In recent years it has often been suspected that the accident frequency is not in itself sufficiently representative for the recording of accidents, especially since, according to the LTI definition, an event in which an employee returns to work but can perform only a reduced range of tasks is not considered an accident. This led to assumptions that the real number of occurring accidents could be significantly distorted in the statistics by “light duty work”. For this reason, the costs of occurring accidents were evaluated over several years together with the Employers’ Liability Insurance Association of the Raw materials and Chemical Industry (BG RCI) and compared with the results of the occupational safety competition. It was found that both figures strongly correlate with each other. In various model calculations, the impact of accident costs on the competition results was examined. It turned out that the inclusion of accident costs only causes a slight change in the placements. It can thus be assumed that the accident frequency figure continues to be a sufficiently representative criterion for occupational safety in the cement industry. Nevertheless, the competition will be regularly examined with regard to the working situation in the plants.

5 Cooperation with the BG RCI

Since the foundation of the working group, its cooperation with the Employers’ Liability Insurance Association, which is permanently represented with one working group member, has been given a high priority. The reports on accidents occurring in other areas of the pit and quarry industry are important impulses for the working group, as is the information on accident prevention assistance offered by the association. In addition, the safety experts of the BG RCI have supported various task groups over the years. Accordingly, it was only logical that the Vision Zero Cooperation Agreement between BG RCI and VDZ was signed in April 2017. As the joint activities on occupational safety are actively organized by the working group, the agreement was signed during its 112th session by the Head of the Working Group Mr. Kai Wagner (Figure 5).

Another important element in the cooperation between BG RCI and VDZ are the seminars for foremen and operational managers. These are organized three times a year by experienced speakers from the BG RCI and assisted by various staff members from the plants (for example, foremen or safety specialists). After a recent decline in the number of participants, the seminar concept was revised at the end of last year. Under the title “Cement Special”, in close cooperation with the working group on occupational safety, a wide range of current topics from operational practice are presented together with new content from the Vision Zero Strategy. By varying the focal points, it is ensured that the seminar remains interesting and refreshes knowledge even in the case of repeated participation. The seminar times and locations have also been optimized. Further information can be found on the BG RCI website under the search term “Cement Special”.

6 Summary

Even though the statistical coverage of accidents and formal legal aspects belong to the remit of the VDZ Occupational Safety Working Group, the work is still largely characterized by safety practice in the plants and, above all, by the people that it ultimately affects. The collaboration with numerous companies makes it possible to quickly clarify critical issues and to provide practical assistive resources. However, this is only possible through the personal commitment of the members of the working group who, in addition to their heavy workload in plants, are prepared to work regularly on the safety topics of common interest.

//www.vdz-online.de" target="_blank" >www.vdz-online.de:www.vdz-online.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.