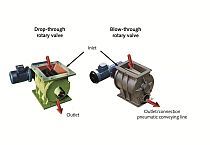

Coperion GmbH from Weingarten/Germany recently supplied and successfully commissioned a wear-protected rotary valve for the RWE Power AG Ville/Berrenrath, Germany coal refinery. The rotary valve type ZXQ with a diameter of 600 mm feeds dry lignite into a pneumatic conveying system that transports the material from a new vertical roller mill to the storage silos. The conveying pressure of the system ranges from 0.9 to 1.1 bar. The rotary valve is designed for a capacity of 60 t/h.

From the outset, this application has demonstrated the advantages of a rotary valve over screw pumps that are...

Coperion GmbH from Weingarten/Germany recently supplied and successfully commissioned a wear-protected rotary valve for the RWE Power AG Ville/Berrenrath, Germany coal refinery. The rotary valve type ZXQ with a diameter of 600 mm feeds dry lignite into a pneumatic conveying system that transports the material from a new vertical roller mill to the storage silos. The conveying pressure of the system ranges from 0.9 to 1.1 bar. The rotary valve is designed for a capacity of 60 t/h.

From the outset, this application has demonstrated the advantages of a rotary valve over screw pumps that are normally used for feeding. So the rotary valve does not constitute a potential igniting source, as the circumferential speed at the normal operating rate is below 1 m/sec. The valve is also available in a flame resistant version. With an operating power requirement of only 4 kW tremendous electrical power savings are possible. Simple maintenance and long maintenance intervals lower operating costs even further. Due to its lightweight design and low operating speeds the valve only requires a compact, simple foundation. These features also result in lower noise emissions.

www.coperion.com