System with many degrees of freedom

Modern mixing plants achieve high throughput rates, quick batch changes and short cleaning cycles while having a small space requirement. The mixing technology presented below is suitable for various building material products, dry products as well as wet masses.

Messrs. KLB Kötztal GmbH in Ichenhausen is a manufacturer of high-quality floor coating systems and paints. Thanks to the development of innovative high-quality products for this sector, KLB has steadily increased its market share in recent years. In 2008, the company therefore drew up a concept for extending their production facilities. Due to the global economic...

Messrs. KLB Kötztal GmbH in Ichenhausen is a manufacturer of high-quality floor coating systems and paints. Thanks to the development of innovative high-quality products for this sector, KLB has steadily increased its market share in recent years. In 2008, the company therefore drew up a concept for extending their production facilities. Due to the global economic crisis, these plans were put on ice for some time, but at the beginning of 2010 the Eirich technical centre commenced tests using KLB’s original formulations. In the course of these tests, the Eirich mixer systems demonstrated their efficiency and flexibility in manufacturing the KLB range of products.

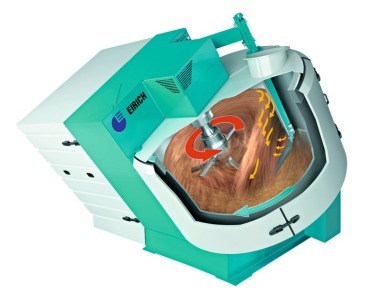

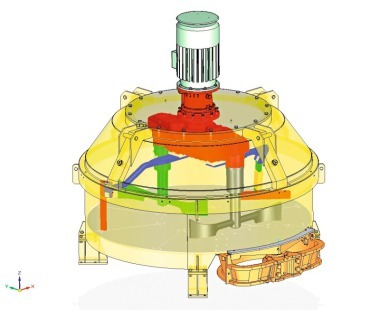

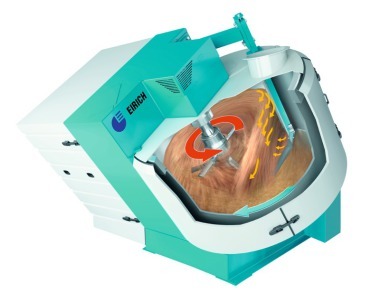

The plant engineering concept comprising an intensive mixer of type R12W and a rotary hoisting lift (quicklift) as a further central element fully satisfied KLB’s requirements and the order was placed in June 2010. Disregarding the interruption during the economic crisis, the realization period for the entire plant from initial enquiry to completion was around 15 months.

Planning for the KLB factory expansion was focussed on a new mixing plant for the manufacturing of a very broad range of building material products. The mixing system would be required to manufacture dry products as well as moist masses. In addition, the planned new facilities included areas for filling, storage and dispatch.

Company management had declared the achievement of maximum possible product quality to be a central objective of the project. Particularly in the field of coatings for industrial floors, KLB had registered constantly increasing demands in recent years, especially with regard to the optical appearance. For modern industrial facilities, customers now often wish to have light-coloured, clean floors and are willing to accept the extra cleaning that this involves. This in turn requires that the floor coating is extremely hard-wearing and durable. For KLB it was therefore particularly important to manufacture mixtures with the greatest possible degree of homogeneity.

1 Architecture

The exterior design of a building of this size in the rural area of Kötztal involved particular challenges. On the one hand the building had to harmonize to the maximum possible extent with its surroundings, and on the other hand it was intended to be unique. For this reason, the architect did not design the tower as a simple square structure, but gave it an obliquely overhanging glass facade. This distinctive architectural feature makes the building noticeable from some distance and quickly made it into a regional landmark, as KLB managing director Artur Kehrle explains. “When we make the next structural modification we will naturally continue to use this design”. The glass facade gives the building a spacious feel and allows bidirectional views to the inside and outside.

2 Storage of the raw materials

Further raw materials, such as limestone meal and aluminium oxide, are delivered by truck in big bags and stored in these bags. The big bags are taken out of storage as necessary and lifted by electric chain hoist to a discharge station at platform level “+4.25 m”, from where the contents are tipped into four additive silos with a capacity of 3 m3 each. Before the big bags are emptied, the plant operator selects the respective silo via an operator panel at the discharge station. The material is then emptied into an intermediate silo. The quicklift then transports the raw materials to platform level “+20.1 m” (Figs. 4 and 5). From that platform the material is distributed by an automatic rotary diverter valve to the previously selected additive silo.

Following the client’s requirements, material supplied in normal-size bags is brought into the system via a bag feeding station, also located on level “+4.25 m” parallel to the big bag discharge station. The contents of the bags are also carried by the quicklift to the respective additive silo, or to the storage bin for small-quantity mixture components.

Dust is extracted from all the transfer points within the mixing plant via a collecting pipe system and conveyed to a central filter. When the levels of the raw materials in the silos fall to a defined level, sensors transmit a signal to the central control panel to inform the plant operator that refilling is necessary. Integral discharge assistance elements in the silo cones ensure that the raw materials cannot form bridges during the subsequent dosing procedure and are reliably and selectively discharged.

3 Dosing and weighing the process materials

Small-quantity mixture components can be manually added through separate feed hoppers on the mixer hood. For this purpose, the plant operator manually weighs the respective components in powder form on a table scales integrated into the control system to obtain the quantity specified in the formulation. He then places the materials in the feed bins and confirms this in the control system. These small component quan-tities are automatically fed into the mixer at the correct point in the mixing process, as defined by the formulation. Integration of the table scales into the central plant control system means that even small manually added quantities are recorded in the batch report and in the balance calculation.

4 Mixing

Feeding the raw materials from the collecting bin into the mixer

Dry mixing of the sand particle size fractions and the binding agents

Manual addition of the small component quantities in powder or in liquid form directly into the mixer

Dry mixing phase 2 with different agitator speed or

Wet mixing phase and granulation of the crumbly products

Discharge of the finished product after a total batch time of approx. 2 to 4 minutes into the downstream bag-filling plant (for powdery products) or bucket-filling plant (for crumbly products)

Complete emptying of the mixer vessel by means of an integral floor and wall scraper

Easy cleaning of the mixer and the tools at every formulation change.

The plant concept also complies with KLB’s requirement for a mixer that permits quick and easy cleaning, because of the processing of widely differing formulations in rapid sequence. “We wish to react quickly and flexibly to customers’ orders and therefore sometimes need to process even small quantities ad hoc”, Artur Kehrle told us. With the employed R12W mixer it is possible to hydraulically swivel up the complete table cover. This enables optimum cleaning after every change of formulation, for example between powdery and crumbly products. Moreover, the integral floor and wall scraper assists the complete emptying of the mixer through a quasi-self-cleaning effect.

5 Product filling equipment

6 Dedusting

7 Plant control

KLB also decided to make use of Eirich’s teleservice. After prior enabling by KLB, the Eirich service team can access the system online from their office in Hardheim to perform possible software modifications or remote diagnosis and elimination of any malfunctions.

8 Conclusions

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.