“State of the art” white cement manufacturing

With a new white cement plant in China the standard for whiteness and quality consistency can be set and raised in a large and very competitive market.

Some of the technologies described in this article are also applicable to the production of grey cement because the main difference is after all the color and not so much the performance of the product in general...

Some of the technologies described in this article are also applicable to the production of grey cement because the main difference is after all the color and not so much the performance of the product in general (strength, setting time and water demand). White cement however is mainly used for special and unique applications where whiteness or color is the most important factor.

1 Background

The plant in Denmark is characterized by the use of rather wet marl (30 % moisture) and this is the main reason for the continued use of the wet process. The higher fuel consumption is offset by recovering most of the heat in the flue gases which is then used in a distributed heating system for the city of Aalborg. The gases from the kiln are first scrubbed for SO2 and the gypsum produced is used in the cement mills. After the scrubber a heat exchanger is installed where recirculation water from the city’s distributed heat system provides 80 000 households with hot water for heating.

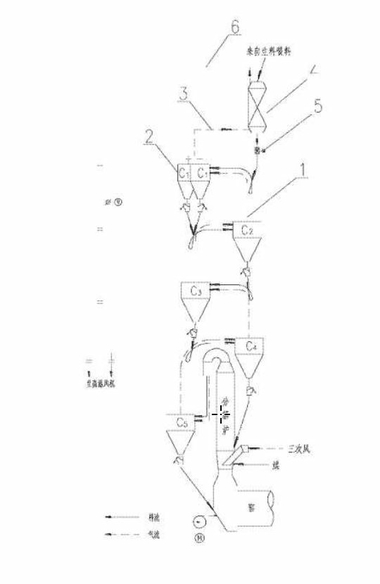

The 3 other plants in the group are located in Egypt, Malaysia and China. The plants in Egypt and Malaysia use conventional white technology where a 4 stage preheater/precalciner kiln provides the heat for drying the raw materials through a heat exchanger located in the down-comer. The clean and now preheated air from the heat exchanger is used as combustion air in the kiln and calciner.

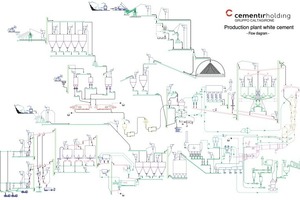

The plant in China (Fig. 1) is somewhat different and closer to “state of the art” because it was process engineered internally by our Group Technical Center and constructed by a Chinese OEM and GC on an EPC basis (Fig. 2). This contract configuration made room for more free thinking compared to what is often possible with an OEM. The description of the process below combines the main features of the newly built Chinese plant and other inputs to what will be done to further improve plant performance in a future project.

What constitutes the difference between gray and white cement apart from the color, is in most cases the application for which it is being used. First of all, the cost of production and thereby the price makes it cost prohibitive for use in large mass pouring but from the point of view of strength and resistance (sulfate), it would do very well and in some cases better than grey cement. The increased light reflection makes it particularly useful in warmer climates quite apart from its decorative value. The added value of white concrete stems from the fact that it does not require repainting, but just cleaning, to remain white.

The whiteness of the cement is mainly the result of the absence of iron, manganese, chromium, titanium and phosphor. The coloring elements just mentioned are typically present in most raw materials for cement manufacture, so only a few cement plants actually have a suitable limestone and almost no plant has, at the same time, the sand and kaolin also required as a silica and alumina source.As a result, these have to be sourced from elsewhere. Finally the burning process for white clinker requires a higher temperature due to the lack of melt in the liquid phase which in part increases the specific fuel consumption. To offset this the plant has implemented the mineralized process, using a compound containing fluor.

2 The ideal white cement process design

It may be tempting to use a vertical mill or even a ball mill for better grinding economy and less heat requirement, for sand and/or pyrophyllite, but potential health issues associated with fine powder containing silica is not recommended and should be avoided.

A better grinding economy is obtained by using a vertical mill for limestone grinding and drying. This configuration has also shown little or no impact on the whiteness because the wear rate on the grinding el-ements containing iron is low.

The slurry produced in the tube mill, is then pumped directly into the vertical mill where the water is evaporated and the material mixed with limestone and kaolin/sand/pyrophyllite. In some cases where sufficient wet milling capacity is available, some or all of the kaolin can be ground with the sand/pyrophylite for tighter control of the acid insoluble residue. The acid insol-uble residue on 45 µm is of paramount importance for burnability and product quality in both white and gray clinker production.

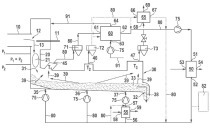

The hot air used as combustion air in the calciner and kiln comes from a grate cooler that follows a rotary cooler. The water quenching in the rotary cooler ensures color and quality and the air cooling in the subsequent grate cooler where the clinker is cooled from approximately 600 °C to 100 °C is first and foremost to provide combustion air and secondly to ensure clinker that can be handled using conventional clinker transport equipment such as pan and belt conveyor. This configuration also limits the amount of water spray necessary in both the rotary cooler and later on in the cement mill.

The conventional location of the clinker crusher at the end of the grate cooler is not really the optimum location. Test have shown that clinker bigger than 25 mm will not be quenched fast enough, allowing the small amounts of FeO to oxidize to Fe2O3 which has a negative impact on the whiteness. To prevent this from happening, a water cooled roll crusher should be installed between the kiln and the rotary cooler. A crusher at this location will also act as a physical barrier, limiting the amount of steam going into the kiln. For our Chinese plant, space has been provided but there are no crushers available on the market that can handle kiln capacities in the range of 1500–2000 tpd which is where the kilns will operate.

Certainly, the future is the introduction of alternative fuel sources but again because of the negative influence of some ashes, the focus right now is on rice husks, solvents, plastics and waste oils. The use of those alternative fuels will not bring down the fuel consumption, on the contrary, but it will certainly reduce the carbon footprint.

A roller press is probably a better application and we do have good experience with this technology from one of our plants, where we can achieve a grinding economy as low as 23.0 kWh/t @ 4000 Blaine. The reason for the excellent power take up in the roller press is to be found in the fact that the wet kilns produce nice round nodules and very little dust. When the roller press is fed with dusty clinker then the power draw drops significantly. Those observations make it doubtful whether a real alternative to the good old ball mill exists, but time will tell. The latest development with vertical mills used for the fine grinding of fly-ash gives us some hope that a technology will become available in the future.

3 Conclusion

The new plant in China has been a great success, allowing the company to set and raise the standard for whiteness and quality consistency in a large and very competitive market.

The equipment selection and configuration together with the mineralized process makes it possible to reach fuel consumptions as low as 1000 kcal/ kg clinker. Trying to recover as much of the excess heat as possible, the energy bill can be reduced still further and in the future a condensing waste heat recovery system, for power generation, could become a reality. The condensing system could be of particular interest in areas where water is a sparse commodity.

Finally the key to becoming a successful producer of white cement, apart from having the right raw materials, is not to be found in the equipment selection alone but in knowledge and know-how. A focus on research and development, a dedicated strategy and proper management of human capital is much more important.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.