Silicones – essentials for cementitious building materials

Silicone based products find widespread use in the construction industry due to the unique properties embodied in the molecular structure. The article provides an insight into the chemistry.

1 Introduction

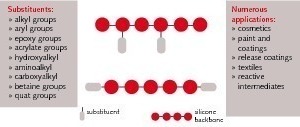

Silicone based products have been used for many years in private and industrial applications, such as automotive, electronic, cosmetic, rubber, tire, textile, leather, paper, household care, paint and construction industries. Starting from simple silicone oils up to sophisticated organomodified siloxanes, silicones hold strong positions in foam controlling, emulsification, corrosion inhibition, dispersing, water repellency, wetting and other interfacial technologies.

Silicones add value to building products. Whether you are sourcing additives for integral or topical building...

1 Introduction

Silicone based products have been used for many years in private and industrial applications, such as automotive, electronic, cosmetic, rubber, tire, textile, leather, paper, household care, paint and construction industries. Starting from simple silicone oils up to sophisticated organomodified siloxanes, silicones hold strong positions in foam controlling, emulsification, corrosion inhibition, dispersing, water repellency, wetting and other interfacial technologies.

Silicones add value to building products. Whether you are sourcing additives for integral or topical building protection, for plasticizer systems for building materials, or mold release, silicone chemistry is present everywhere. They are being used as performance and processing aids for various applications such as paver stones, pre-fabricated concrete, ready-mix concrete, drymix mortars (self leveling underlayments, stucco/render, grouts) and construction materials.

2 Silicone chemistry

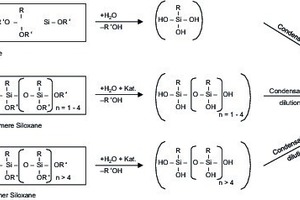

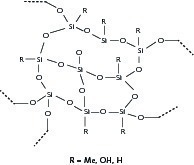

Silicones cover a broad physical spectrum of low viscosity oils, greases, rubbers and resins. The Rochow process is the most common technology for preparing organosilicones on an industrial scale. Starting point is the Rochow synthesis where alkylchlorides react with silicon in the presence of copper catalysts to alkylchlorosilanes. These silanes can be separated by distillation [1].

2.1 Rochow Synthesis

Si + CH3Cl ————>– (CH3)2 SiCl2 = Main product

(CH3)3 SiCl, CH3SiCl3, SiCl4,

CH3HSiCl2, (CH3)2 HSiCl

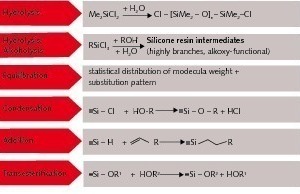

Polaric siloxane functions like SiCl, Si-H or SiO-alkyl have a higher reactivity compared to the equivalent carbon compound and can be readily transformed by esterification, transesterification, condensation, addition and hydrosilylation to silicone copolymers for the synthesis of modified siloxanes. This special reactivity plays also a keyrole for the synthesis of organomodified siloxanes [2].

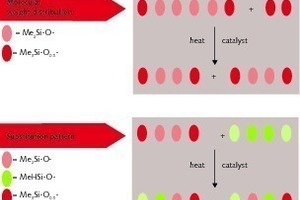

2.2 Equilibration – from monomeric/oligomeric

to polymeric

The equilibration reaction plays a special role in the silicone chemistry. During this reaction forced by strong acids or alkalines the Si-O-Si bonds are cleaved and reformed to a polymer distribution which corresponds to the thermodynamic equilibrium [3]. Based on this technology, a highly reproducible synthesis of corresponding products, like silicone oils or alkoxy-siloxanes can be achieved.

3 Properties of silicones

The big success of silicones is related to the diversity of their properties. Beside their thermal stability and high weather resistance their viscosity is less influenced by temperature changes. Even at low freezing points they keep their elasticity. The relatively low surface tension of 22 mN/m provides water repellency and high surface activity which reflects the low intermolecular interaction of silicone oils for their use as release agent, lubricants or defoamers. Almost all silicones are biologically inert and nontoxic.

Silicones are highly efficient, therefore the dosages in the applications are relatively small compared to other non-silicone based materials. Dosages of 0.2 % or less are mostly used in applications to improve the quality or durability of the final materials.

4 Silicones for the use in cementitious

construction materials

The major properties of silicones in cementitious construction materials are

Water repellency

Efflorescence control

Airvoid controlling

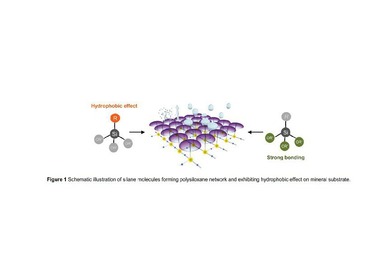

4.1 Water repellents based on silane/siloxane technology

Among all different kinds of hydrophobic products developed for the building industry, silicone resins, silanes, oligomeric and polymeric siloxanes have proven to perform best in protecting construction materials from water penetration and environmental influences. They are supplied in several conditions depending on applications. Silane/siloxanes provide outstanding water repellency and an excellent beading effect along with true long term performance resulting in sustainable protection of buildings and architectural constructions [5].

By adding silane/siloxanes to concrete or mortars the water uptake can be reduced by more than 90 % referred to the untreated reference. Admixtures based on silicones prevent primary efflorescence during the curing of the concrete. As a result fading of pigmented products can strongly be reduced or even eliminated. Furthermore, salt blooming which is known as secondary efflorescence is reduced as well [6, 7].

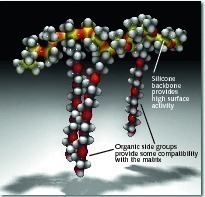

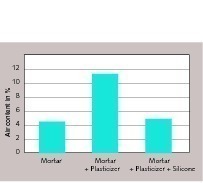

4.2 Defoamer based on organomodified siloxanes

Surface activity and compatibility seem to be somehow contradictory. Whereas silicone oils have a high surface activity but a low compatibility, organic oils are often quite compatible with many systems but often lack surface activity. The combination of both properties can be achieved by so-called organomodified siloxanes [8]. They are based on a polydimethylsiloxane (i.e. silicone oil) backbone, with attached organic side chains (e.g. copolyethers of ethylene oxide and propylene oxide). Compatibility is always requested when concrete plasticizers need to be defoamed. Worse compatibility of the defoamer with the plasticizer leads to separation and insufficient storage stability over time.

Therefore, most of the physico-chemical and application properties of OMS are determined by the length of the siloxane backbone and the number and nature of the organic grafts. Whereas the silicone backbone provides the low surface tension (typical for silicones) which is required for the spreading coefficient to be positive, the organic grafts can be used to control the compatibility of the OMS with the matrix.

In addition to their defoaming performance organo-modified siloxanes offer further advantages during application. They are known to positively influence the wetting of hydrophobic surfaces when added in smaller amounts (< 1 %) to aqueous formulations. Wetting of the powdered, inorganic particles of the mortar formulation by water means that adhering air bubbles might be displaced from the surfaces of the particles [10, 11].

//www.evonik.com/construction-chemicals" target="_blank" >www.evonik.com/construction-chemicals:www.evonik.com/construction-chemicals

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Fluidized-bed reactor for the production of alkylchlorosilanes [2]](https://www.zkg-online.info/imgs/tok_9a038d63992352419e378bd9ebd2367e/w203_h178_x101_y89_101543069_95bc9ca18c.jpg)