Rotary kiln ring on 16 axles and a steep gradient

Today’s heavy haulage challenges call for top quality products. That is why specialists for heavy haulage and oversized cargo transportation such as Bohnet GmbH of Kirchdorf (Baden-Württemberg/Germany) come into play – their advantage is not only the daily routine in “playing” with extraordinary loads, but also the equipment made for these transports. One of the manufacturers is Goldhofer AG from Memmingen in Bavaria.

The latest example of perfect cooperation between the two companies was the shipment of a huge rotary kiln ring to the Schwenk cement works for ThyssenKrupp Resource Technologies:...

Today’s heavy haulage challenges call for top quality products. That is why specialists for heavy haulage and oversized cargo transportation such as Bohnet GmbH of Kirchdorf (Baden-Württemberg/Germany) come into play – their advantage is not only the daily routine in “playing” with extraordinary loads, but also the equipment made for these transports. One of the manufacturers is Goldhofer AG from Memmingen in Bavaria.

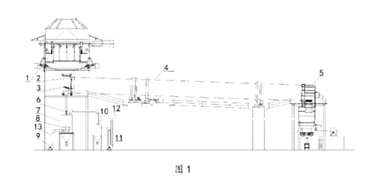

The latest example of perfect cooperation between the two companies was the shipment of a huge rotary kiln ring to the Schwenk cement works for ThyssenKrupp Resource Technologies: straight across Europe from Ostrava in the Czech Republic to Allmendigen in the Swabian Alp region of Germany – with challenges great and small en route. The 16 THP/UT heavy-duty axle lines used for the job had only recently been collected by General Manager Peter Bohnet and his team in a little ceremony held at the Goldhofer plant (Fig. 1). Before that, in spring 2012, Bohnet had already acquired thirty THP/UT axle lines and two vessel bridges and a drop deck from Goldhofer.

Bohnet’s team promptly proved him right regarding his trust in the new equipment in an impressive demonstration with the rotary kiln ring. The huge steel ring (with a diameter of 8 meters) took four whole weeks to complete the journey, which included its fair share of obstacles. For their part, the logistics experts at Bohnet worked for a good six months to ensure that there would be no nasty surprises on the highways, although they know as well as anyone that, no matter how careful the planning, the unforeseeable can always occur.

And it did, starting with the weather gods, who seemed determined to cause maximum trouble for the project: Because the River Elbe was in flood after days of continuous rain, the original route was not available, and an alternative first had to be checked for the load-bearing capacity of the roads and other risks. The decision was finally taken to load the rotary kiln ring onto a barge in Melnik in the Czech Republic and transport it to Duisburg in Germany, where it was transferred to a River Neckar barge and taken to Stuttgart. There a mobile crane waited on the quay to lift the 265-ton rotary kiln ring onto the 16 Goldhofer THP/UT axle lines.

For the logistics experts, that marked the beginning of some challenges they had not reckoned with: Because the responsible officer at the traffic authority had such a high workload and his assistant was on holiday, the permit for the journey had not been issued in time, and it was only thanks to the local police that the wide load was able to leave the port. But not even they could help when the route along one of the main thoroughfares in Stuttgart was found to be blocked by dozens of parked cars. There were “No Parking” signs everywhere, but more than forty drivers seemed not to have noticed them – and German law does not permit parked cars simply to be towed away.

The next obstacle was the hills of the Swabian Alp, with roads so narrow that the 16 axles had to be replaced by twelve for greater maneuverability over part of the distance (Fig. 2). In the town of Nürtingen, for example, a few millimeters decided between success and failure: The cargo was exactly two millimeters higher than permitted at the narrowest points on the roads, but with some precision maneuvering and gentle persuasion applied to a few tree branches, the tractor-trailer combination was once again able to pass – and proceed to the next challenge: A road junction had to be closed to traffic, which again added to the final bill. The application to close the junction had been submitted weeks before, but the authorities only issued the official notice two days before the requested date. “Sometimes you feel like tearing out your hair,” said Stefan Fuchs, CEO of Goldhofer Aktiengesellschaft.

The journey over the Swabian Alp to Allmendingen took three consecutive nights, and the logistics experts had to pull out all the stops. On the steep incline known as the Beurener Steige, progress dropped to walking pace. A total of 290 “No Parking” signs were erected, three sets of traffic lights removed, overheated cylinder parts replaced, and no end of curb protection plates and temporary road plates laid. All that was hard physical work, but the crews had no problems. So the rotary kiln ring finally arrived as planned and still on time in Allmendigen.

Such “little problems” do not give Bohnet’s experienced planners any gray hairs. Nor did they have to worry about the vehicle chosen for the job: The THP/UT axle lines from Goldhofer AG turned in a superb performance. With the help of Bohnet’s own mobile crane, the rotary kiln ring was transferred to a low loader and installed in the cement plant, bringing to a close yet another exciting heavy haulage mission – to the great satisfaction of the Goldhofer and Bohnet crews, who had a joint achievement to celebrate.

Bohnet’s new UT heavy-duty modules are suitable for both construction site working and long-distance haulage. The twin-tire axle lines are fitted with BPW disk brakes for maximum control and safety. With a suspension stroke of +350/-250 mm and an extremely low loading height, Bohnet can use the Goldhofer UT axles for most of its varied heavy haulage activities. The modules can be deployed in both longitudinal and parallel combinations.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.