Predictive maintenance reduces

downtimes and maintenance costs

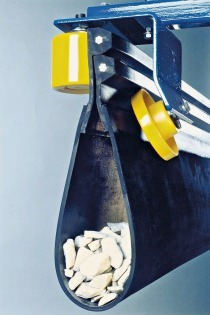

Whether in open-pit or underground mining, for steep inclines or across distances spanning kilometers – conveyor belts are the core component of many industrial sectors. In harsh operating conditions, they transport loads weighing several tons not to mention sharp, hot, oily and greasy goods. Smooth running of these belts is crucial for cost efficiency. If the belt system experiences an extended downtime, the entire production chain frequently collapses. This in turn results in considerable sales losses for the operators. To allow conveyor belt systems to run free of faults and...

Whether in open-pit or underground mining, for steep inclines or across distances spanning kilometers – conveyor belts are the core component of many industrial sectors. In harsh operating conditions, they transport loads weighing several tons not to mention sharp, hot, oily and greasy goods. Smooth running of these belts is crucial for cost efficiency. If the belt system experiences an extended downtime, the entire production chain frequently collapses. This in turn results in considerable sales losses for the operators. To allow conveyor belt systems to run free of faults and cost-effectively in the long term, even when subjected to high loads, the operators are focusing more and more on prevention. Innovative electronic monitoring systems make it possible to identify the exact condition of the conveyor belts at any time.

More serious damage such as longitudinal slitting or splice faults on the conveyor belt can have serious consequences for system operation, and lead to total failures in a worst-case scenario. The monitoring system Conti MultiProtect helps to detect such damage at an early stage during operation and to repair the damage in good time. This helps to avoid extended downtimes. The way it works is that rip inserts implanted into the conveyor belt check for longitudinal slitting by means of their characteristic magnetic fields. Using RFID (radio-frequency identification) chips, ContiTech has been able to optimize localization of longitudinal slitting on the belt. Conti MultiProtect is also able to monitor the condition of the joints and identify damaged spots within the carcass. The user-friendly system has an intuitive operating design that uses a graphical interface.

This permanent monitoring gives us a detailed picture of the condition of the conveyor belts at all times without having to interrupt operations. This allows cover repairs to be scheduled preventively in good time, thereby reducing maintenance costs outlining the advantages further. ContiTech uses software developed in house.

//www.contitech.de" target="_blank" >www.contitech.de:www.contitech.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.