Official launch of East Malaysia’s first integrated cement grinding plant

By May 2016, Christian Pfeiffer successfully handed over its first turnkey cement grinding plant in Malaysia, which includes raw material handling and finish product storage silos as well as a fully automated packing plant, to Cahya Mata Sarawak (CMS).

1 Introduction

The EPC contract in the frame of FIDIC regulations was signed in May 2014. From engineering, purchasing, logistics up to the execution of civil, steel, mechanical, commissioning, electrical and automation works also the whole infrastructure as well as all local permit procedures were successfully carried out by Christian Pfeiffer.

The aim of this project was CMS’ wish to increase its cement production with a reliable and energy efficient state-of-the-art grinding plant, capable of delivering various cement types in bulk, big-bags and 50 kg bags in loose or palletized form, with or...

1 Introduction

The EPC contract in the frame of FIDIC regulations was signed in May 2014. From engineering, purchasing, logistics up to the execution of civil, steel, mechanical, commissioning, electrical and automation works also the whole infrastructure as well as all local permit procedures were successfully carried out by Christian Pfeiffer.

The aim of this project was CMS’ wish to increase its cement production with a reliable and energy efficient state-of-the-art grinding plant, capable of delivering various cement types in bulk, big-bags and 50 kg bags in loose or palletized form, with or without pallets.

The new plant is located next to an existing rotary kiln line in Mambong, Kuching. The clinker produced is directly fed to the new mill from an existing clinker silo, hence avoiding having to transport the clinker to the existing grinding station in Pending, a distance of more than 30 km. Any additional clinker requirement for the Pending plant, which is located near the sea, can be imported. Thus, significant savings in the overall logistic costs are achieved.

2 Description of the new grinding plant

The heart of the plant is a two-compartment ball mill with a diameter of 4.8 m x 15 m effective grinding length (Figure 1) equipped with a high efficiency separator QDK 248-Z (Figure 2) designed to produce 150 t/h cement with a fineness of 3500 cm²/g acc. Blaine. The mill is supported by slide shoe bearings and driven by a lateral drive unit consisting of girth gear and two pinion gear box with floating shaft and a 5600 kW main motor. The feed materials comprising clinker, gypsum and limestone are dosed separately via weigh feeders, while fly ash can be added directly to the separator by a bucket elevator. To ensure the most effective comminution the ball mill is equipped with progressive lifting and classifying liners and filled with Allmax grinding balls. The material flow from the first to the second compartment is regulated by a Christian Pfeiffer intermediate flow-control diaphragm in Monobloc design, to ensure an ideal material level and particle size for fine grinding in the second compartment. The finely ground cement leaves the mill by a discharge diaphragm – also in Christian Pfeiffer Monobloc design – and fed to the separator circuit by a bucket elevator.

The Christian Pfeiffer cross-flow separator QDK 248-Z has a very high separating efficiency and low bypass, easily reaching the required cement fineness with low recirculation rates (Figure 3). Separation of the ground cement is achieved by a high efficient, low energy bag filter application with minimum remaining dust content in the clean gas of below 10 mg/Nm³. Thereby the plant easily meets the requirements of the local authority and the customer’s demand for a modern and eco-friendly plant. By using a continuous online monitoring system, which is directly linked to the government environmental control department, the appropriate verification is conducted.

The cement produced is stored in two interchangeable 10 000 t silos, one mono and the other duo-cell, thus allowing the production and storage of three different types of cement. Each silo is equipped with two bulk loading devices for conventional silo truck loading. Cement for the adjacent packing plant is transported via air slides and a bucket elevator. There it can be filled into big-bags or cement paper bags by a rotary packer performing with 3000 bags/h. The single packed cement bags can either be directly loaded onto trucks or be transferred to a palletizer. This fully automated palletizing system is designed for both pallet and palletless operation.

3 Project realization

Christian Pfeiffer has long been known for its supply of equipment or semi-turnkey projects. Several EPC projects have been successfully realized within the last 10 years. This project represented the first challenge for Christian Pfeiffer to undertake an EPC project in Malaysia. From engineering, procurement, logistics to the execution of the civil, structural steel, mechanical, electrical/automation works and commissioning, including all the infrastructure and application for all necessary local permits were successfully accomplished by Christian Pfeiffer and its local subsidiary especially set up for the project.

CMS Group Managing Director Dato’ Richard Curtis (Figure 4) summarizes his experiences: “When we planned this plant, we were very aware of the challenges we would face in the event of any unplanned shutdown. Unlike in Peninsula Malaysia, it takes too long to import either cement or spare parts if there is an unscheduled shutdown. Thus our decision on the plant’s supplier was not just price driven but reliability driven. This is why we were pleased to award the engineering, procurement and construction contract on a turnkey basis to a leading German company, Christian Pfeiffer Maschinenfabrik. Christian Pfeiffer has a long and proud heritage dating back to 1925 and they have done an excellent job working in a spirit of positive collaboration, to deliver the plant on schedule, on budget and exceeding its expected performance levels.”

During the engineering and design phase all know-how was brought together for an efficient selection and purchasing of imported equipment to ensure timely delivery. A special challenge was posed by the transportation of the big Ø 4.8 m x 15 m length mill shell from Europe to Malaysia. Amongst other things, a pedestrian bridge had to be lifted and various power cables had to be cut off allowing the low-loaders to reach the project site. This task was accomplished without any “hiccup”.

During the plant layout design phase the attention was especially drawn to a maintenance friendly concept with good accessibility of drives by platforms and hoists. Other engineering servi-ces like static calculations of buildings, foundation plans, structural steel drawings or design of cables were outsourced to longtime engineering partners and successfully carried out under supervision and in cooperation with Christian Pfeiffer as the general contractor.

The tropical climate on the island of Borneo confronted the company with the challenge of working under contrarious climatic conditions and together with unknown local sub-contractors. Consistently heavy rain during monsoon time hindered the excavation works for the building foundations. Also the persistent high temperatures and high humidity caused maximum stress to humans and machines. The location of the site also necessitated the shipment of some materials and machinery from West Malaysia as various items were unavailable locally.

Nonetheless, due to good cooperation with the local sub-contractors all requirements were settled to finish each section. Thanks to a good structural steel fabrication quality and fast erection the preconditions for the following installation of peripheral equipment around the core components were realized, before the next big tasks of cable termination, medium voltage, automation and infrastructure including road works continued. The connection of the medium voltage switch gear was done to the customer’s existing network.

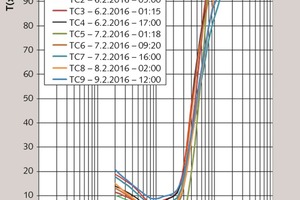

By the end of December 2015, after nearly 18 months with the ongoing support of the customer and close cooperation of both parties, the first silo was filled with high quality cement allowing CMS to sell finish product. During the following performance test over 4 x 20 hours Christian Pfeiffer was able to achieve all contractual guaranteed values and proved that the plant “Made in Germany” distinguishes itself with its high reliability and energy efficient operation. The whole plant, starting from the existing clinker silo discharge up to the complete grinding plant, cement transport to silos, bulk loading, packing plant and palletizing system performs with a specific power consumption of 39 kWh/t at a fineness of 3500 cm²/g acc. Blaine.

With further process optimization the new grinding plant proved to be capable of reaching smoothly throughput rates above 160 t/h at 3500 cm²/g acc. Blaine. During the official handing over ceremony in November 2016 Dato’ Richard Curtis expressed his satisfaction: “This third plant will increase CMSB’s total annual rated cement production capacity by almost 60 % to 2.75 million t, well above current local demand of around 1.7 to 1.8 million t. This will enable CMS: to meet growing cement demand in Sarawak, including from upcoming big projects such as the Baleh dam and the Pan Borneo Highway, to have significant reserve production capacity to materially reduce the risk of supply disruptions, to extend our supply into nearby export markets as well as to produce more than one type of cement.”

//www.christianpfeiffer.com" target="_blank" >www.christianpfeiffer.com:www.christianpfeiffer.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.