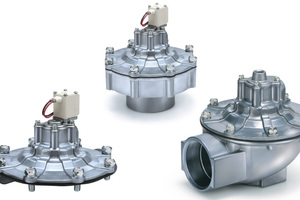

New, flexible dust filter valves

SMC Pneumatik in Egelsbach, near Frankfurt/Germany, has optimized its series VXF dust filter valves designed as 2/2-way solenoid valves and as pneumatically actuated valves. With numerous connection sizes from 3/4” to 4”, the series VXF has now also been made suitable for large piston diameters. Numerous types of connection are available, such as a threaded end that can be directly connected to a pipe, and a flanged version for direct connection to a container.

Thanks to the double diaphragm structure for pilot valve and main valve, response times are short. The nominal diameters of between 22...

SMC Pneumatik in Egelsbach, near Frankfurt/Germany, has optimized its series VXF dust filter valves designed as 2/2-way solenoid valves and as pneumatically actuated valves. With numerous connection sizes from 3/4” to 4”, the series VXF has now also been made suitable for large piston diameters. Numerous types of connection are available, such as a threaded end that can be directly connected to a pipe, and a flanged version for direct connection to a container.

Thanks to the double diaphragm structure for pilot valve and main valve, response times are short. The nominal diameters of between 22 and 100 mm assure high flow capacities and consequent quick venting of the bag. Almost all models of the dust filter valve are very energy-efficient, having a very low power consumption of only 4.5 W. The improved design has also extended the service life of the valves. Their elastic damping disk reduces the switching noise so effectively that the series can even be used for low-noise environments. Moreover, an additional silencer option is available.

The series VXF can be optimally controlled by means of a valve controller (series VXFC) with six and ten outputs, which switches a number of valves for the dust filter on and off.

The VXF-series dust filter valves from SMC Pneumatik vent compressed air at high velocity, cleaning the bag filter by shockwave. They can be used in any type of dust filter system and in any size of industrial unit. They have found application, for instance, in the iron and steel industry, in chemical and pharmaceutical works, in the cement conveyance and particle conveyance sectors, in refuse incineration plants, in the foodstuffs industry and in the timber industry.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.