Loosen, mix and transport powdery goods with compressed air

In general, the production of powdery goods is not possible without compressed air as this medium is essential for important transport, loosening and/or homogenization tasks. This refers also to the production of cement.

1 Compressed air in the cement industry

1 Compressed air in the cement industry

One of these blowers in the central station comes from the new Aerzen series “Delta Hybrid” (Fig. 4). For the first time, this series combines the advantages of a positive displacement blower and a screw compressor to a new convincing compressed air concept. This is why Aerzener created the name “Rotary Lobe Compressor”. The outstanding property of all packed units of the new series “Delta Hybrid” is the maximum possible pressure, up to 1.5 bar with continuous operation.

2 Cement production in Karsdorf

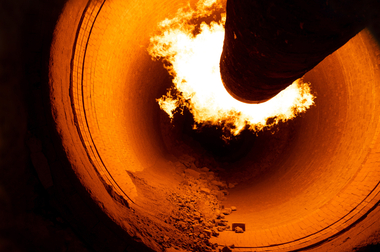

The raw material limestone necessary for the production of cement is found at Karsdorf in the company’s own open cast mining very close to the plant. After storing and grounding in the raw mill together with other additives, the material is transferred pneumatically into the kiln. The kilns are fired by pulverized lignite that is transported by conveying air of Aerzen screw compressors whereas Aerzen positive displacement blowers are used for the generation of combustion air in the kilns. The cooled clinker is mixed with other additives depending on application and afterwards ground to very fine cement and mainly removed by silo trucks.

3 Loosening, mixing and conveying

In the past positive displacement blowers were the ideal producer of compressed air up to a maximum pressure of 1 bar. They have proved to be of value in this pressure range and for most different applications – even in continuous operation under extreme conditions – for decades in many industries as producer of absolutely oil-free compressed air. But so far 1 bar maximum pressure for positive displacement blowers has been the end of the line. Because of this, oil-free compressing screw compressors had to be applied for the pressure range of 1 bar to 1.5 bar, a range very often requested. This is why Aerzener Maschinenfabrik, an experienced producer of positive displacement blowers (since 1868) and screw compressors (since 1943), has put this topic into the focus. Aerzen designers created a completely new compressed-air production concept with the development of the new series Delta Hybrid. With the new packed units of the series Delta Hybrid compressed air can now be produced for the first time for the difficult pressure range of 1.0 to 1.5 bar in the most reliable and economic way besides the common application for the range up to 1.0 bar maximum pressure. These packed units had been developed to series production readiness under real field conditions for several years. A packed unit of the series Delta Hybrid has been operating continuously since February 2007 in the cement plant in Karsdorf and has proved to be of value even under the extreme conditions of the cement industry.

The cement plant in Karsdorf has three kiln lines, two of them are currently active and named internally line 3 and line 4 (Fig. 5). The compressed air has two central tasks in this production chain: to loosen and to homogenize the raw meal in the silo plant, to transfer it via a dosing system into conveying systems and – pneumatically as well – to transport the raw meal via piping systems to the kilns. The compressed air required in all operation ranges is generated by air-cooled packed units from Aerzener Maschinenfabrik all installed in a big hall.

The compressed air required for loosening of the raw meal in the storage silo and for homogenization is provided by two packed Aerzen units operating continuously; a positive displacement blower and a packed unit of the new series “Delta Hybrid”. A third blower is provided as redundancy; a fourth packed unit is available for other tasks. All four packed units operate in the pressure range of 0.6 to 0.8 bar.

The compressed air required for the raw meal transport and for another homogenization is provided by four big oil-free compressing air-cooled Aerzen screw compressors type VM 537 (quantity delivered 96 m3/min each; pressure range 2.6 to 3.3 bar depending on demand). One of these compressors supplies the compressed air for the transport, two packed units produce the compressed air for the uniform mixing of the materials (homogenization) and a fourth compressor is held available as redundancy. Since commissioning these four plants have operated 114 900 hours, 117 800, 34 500 resp. 38 400 hours (as of June 2010).

4 Higher efficiency through speed control

At first, Aerzener Maschinenfabrik sent a quotation to the cement plant in Karsdorf for a packed unit from the newly developed series “Delta Hybrid” for testing purposes. To achieve the maximum possible degree of capacity utilization, this unit was directly integrated into a kiln line where the supply can be converted to a redundancy unit in the event of an accident or emergency. “This new test blower has been operating continuously without any difficulties from the start-up more than three years ago and supplies compressed air with a maximum pressure of 0.8 bar”, reports Günter Schlimm. Until then three of the four existing Aerzener positive displacement blowers operated for the loosening and homogenization process of the raw meal in the silo according to the following concept:

One blower each was allocated to one of the two kiln lines producing the compressed air required in this range for loosening and homogenization of the cement meal in the silo. The 3rd unit was held available in reserve and could supply the kiln line 3 and kiln line 4 as well if necessary. In principle, this concept still applies today, but the commissioning of the new “Delta Hybrid” blower in February 2007 brought the instant decommissioning of the old main unit of a kiln line.

5 New series for different rating ranges

The new Delta Hybrid units are available in the following rating ranges:

Volume flows: 10 to 70 m3/min (600 to 4200 m3/h)

Fields of application: for air pressure, over pressure and vacuum pressure

Pressure range: 0 to 1.5 bar

Intake range: up to minus 0.7 bar

Especially favourable price performance-ratio considerably below the investment, energy and maintenance costs for a comparable turbo or screw compressor

Insignificant capacity fluctuations compared with a turbo compressor even at different intake temperatures (summer-/winter operation) or at pressure fluctuations;

Significantly improved energy efficiency by energy savings up to 15 % compared with usual units

Low maintenance and service costs

Solid bearing design (durability 60 000 operating hours, also with maximum load)

Low compressed air discharge temperatures thanks to excellent thermal budgets, compact dimensions, belt drive, belt tension by hinged motor mounting plate, side-by-side installation, front-side operation, oil inspection and refilling during operation, low noise level, optional control AS300 AERtronic, appropriate for external installation

Very high control range (25–100 %), easy to operate and to maintain

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.