Lifecycle orientation in industrial facility construction

Changing conditions in the economic environment demand continuous adaption. This not only applies to business processes or production equipment, but particularly the industrial facilities too. Adaptability can be assured with appropriate parameters such as scalability or modularity. For a future-viable industrial facility therefore, in addition to the initial design and realization costs, the operating costs and especially the change costs must be considered in the scope of a lifecycle cost analysis.

1 Introduction

Since the beginning of industrialization, industrial construction has undergone significant changes. Whereas individual workshops used to dominate, as industrialization progressed, large complex factories grew up. To begin with, this new form of industrial building only had to provide sufficient space for the many workers and machines. With the demand for increasing effectiveness and efficiency in production, however, the building had to meet increasingly specific requirements. For the first vehicle to be manufactured on a large scale, the Model T Ford, for the first time an...

1 Introduction

Since the beginning of industrialization, industrial construction has undergone significant changes. Whereas individual workshops used to dominate, as industrialization progressed, large complex factories grew up. To begin with, this new form of industrial building only had to provide sufficient space for the many workers and machines. With the demand for increasing effectiveness and efficiency in production, however, the building had to meet increasingly specific requirements. For the first vehicle to be manufactured on a large scale, the Model T Ford, for the first time an entire factory was designed to meet the requirements of production and particularly of the material flow for this one product. However, the change from a seller’s to a buyer’s market and increasing globalization forced manufacturers to adopt ever shorter product lifecycles and offer a constantly increasing number of variants.

While the Model T was manufactured almost unchanged for another 20 years following its launch, nowadays vehicle models are superseded after around five years and every manufacturer supplies a wide range of different models and derivations in an almost infinite number of configurations. Organization in the factory used to be mostly task-oriented, so that the machines were grouped according to the manufacturing principle, e.g. turning shop, grinding shop or assembly shop. In today’s factories, machines are arranged in line with the material flow of the respective product family. When products are changed, this frequently necessitates modifications to the manufacturing layout. The increased complexity and the higher requirements for productivity also have an impact on the industrial facility. The constant change in production already has to be taken into consideration in the design and realization of the industrial facility, to minimize lifecycle costs rather than just investment costs.

Basically, this requirement can be met with two approaches. The single-use factory, designed to meet short- and mid-term requirements, can be realized cheaply and quickly at the location of current demand or favorable conditions, e.g. minimal wages. The characteristics of this factory are oriented to the specific lifecycle of one product. If conditions change, for example as a result of increased wage costs, the factory is abandoned and in the best case individual machines are dismantled and reused elsewhere.

The opposite approach to meeting changing conditions is the adaptable factory. In this case, possible courses for the lifecycle of a factory are already anticipated and taken into consideration during design. Despite the trend towards the relocation of production to Asia and Eastern Europe, especially in the case of premium manufacturers, a long-term and sustained orientation of the production sites can be increasingly identified. Against this background, lifecycle orientation in industrial construction is moving more and more into the focus of design.

2 Changing requirements

Requirements for manufacturing companies and therefore also for industrial facilities are subject to constant change and have considerable impact on industrial facility construction.

The range of variants of many products is growing steadily. This strong increase in the range of variants is caused on the one hand by the greater individuality of customer requests, to which the manufacturing companies respond with niche products. On the other hand, the opening of new markets with different local requirements, to cater, for example, for the local climate, culture or legislation within the scope of globalization, demands specific product variants. Shorter innovation cycles and fast-changing technologies, both on the production and application sides, lead to ever shorter product lifecycles. This necessitates almost constant changes in the production, in respect of machinery and equipment, but especially with regard to the layout as well as the production and logistics processes.

The wider range of variants, the increasing competition and the shorter product lifecycles lead overall to poorer predictability of the success of a product. External events, like for example natural catastrophes or political unrest, cause further turbulences. Not least, legislators intervene in the markets to regulate these and thereby create new conditions. One example is Germany’s environmental bonus, also known as the scrapping incentive, which led to distortion on the car market both with regard to the market shares of the competitors and the vehicle categories. The result was wide differences in the capacity utilization of the car manufacturing plants within a group and efforts to redress these differences.

In addition to the above-mentioned requirements, the customer also demands high transparency over the processing of business transactions. For the company itself, this is imperative to maintain an overview within global corporate networks. The need for a constant availability of information demands modified IT systems, for example with the application of RFID technology and adapted forms of organization. Inside the industrial facility too, transparency must be ensured, for example, by means of visualization. Here, key prerequisites for this are created during design.

To recap, the requirements for companies can be summed up in the demand for greater adaptability. The company must be in a position to adapt very quickly to new conditions. This requires appropriate provisions to be made not only in the infrastructure and the organization, but also in the production facilities.

3 Adaptable industrial facilities

One possible solution to adequately meet the changing requirements is the adaptable factory. Adaptability is the ability of a factory to actively change its structure with regard to equipment, organization, technical installation and facility engineering to meet new internal or external requirements [7]. The adaptability can therefore be construed as the sum of flexibility, reactivity and cost efficiency. In this context, flexibility describes the ability to react to pre-meditated scenarios, while the reactivity describes the ability to act beyond the premeditated dimensions. The third aspect of adaptability is the cost efficiency, the guiding priority for all business activities [6]. The necessity of adaptability in the factory becomes clear in an analysis of the lifetime of the individual factory elements. While the building and facility engineering can be used for several decades, the lifecycle of machines, equipment and resources is limited to a few years. In a factory building, inevitably different product equipment for different products and technologies has to be installed and makes different demands on the infrastructure [4]. Therefore, adaptive industrial facilities that can be used neutrally are needed. After the end of the originally envisaged use, conversion must be possible simply, quickly and at low cost. If a factory is planned, for instance, as a supply plant for a single customer, the company will not have any further use for this factory if this order is cancelled. Sale of the factory can then be an expedient alternative. The more adaptable the factory is and the wider the potential uses of the factory are, the larger the group of potential buyers and the higher the sales price achievable for the factory.

The preconditions for a trouble-free changeover to new production technologies and the associated changes in the layout and the building are created during the design of the factory. Ensuring the necessary adaptability is a key function in the design and realization of industrial facilities and must be regarded as a permanent goal during design. The adaptability of an industrial facility can be evaluated on the basis of five change enablers [7]:

Scalability: This ensures extensibility and reducibility in respect of equipment, labour and space. For example in industrial facility engineering, space for later expansion and possible extension of the building must be taken into account during design and planning.

Modularity: Standardized, pre-tested functional units in respect of engineering as well as organization ensure less expensive and fast exchangeability between them. So one manufacturing cell be replaced with little effort with a storage area providing the necessary, standardized media supply (compressed air, IT connection, etc.) is available and the space elements used are standardized in size.

Compatibility: Compatibility allows the connection of the modules in respect of information and material flows, energy and media. For this, for instance, uniform interfaces are needed in the energy supply or between software systems.

Mobility: Unrestricted mobility of the objects in the factory as well as of the building and building elements reduces the expense of repositioning the objects if this becomes necessary.

Universality: The change objects should be universally applicable in respect of product and technology requirements, to ensure that these are suitable for various duties, requirements or functions in the lifecycle of the facility.

The actual adaptability of an industrial facility is often only demonstrated over many years of operation, although the preconditions for the adaptability are already created during design and realization of the facility. In the following therefore the lifecycle of an industrial facility is described with the phases influencing its adaptability.

4 Lifecycle orientation in industrial

facility construction

Every product is subject to a lifecycle, which describes the time interval between design and decommissioning [1]. The individual phases of this general cycle are as follows [1]:

concept and definition

design and development

production

installation

operation and maintenance

disposal

Every product, and therefore an industrial facility too, undergoes a comparable cycle. The lifecycle and its phases described in general for products can be simplified for industrial facilities. The first two phases (“Concept and Definition” as well as “Design and Development”) can be summarized under “Design” for industrial facilities. The “manufacture” of a product corresponds to the realization of the facility. For primary products, the “installation” of a product is not an independent lifecycle phase; this is only the case for vendor parts. For an industrial facility too, this phase does not exist. Compared to other products, the two early phases of design and realization are relatively short compared to the utilization phase for industrial facilities.

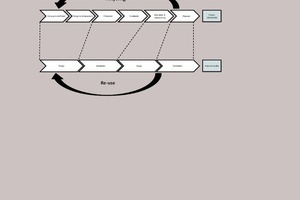

At the beginning of the lifecycle, however, many of the key characteristics of an industrial facility are determined. Besides the design, especially the running or ownership costs and the change enablers (Fig. 1) are defined. The “Operation and Maintenance” phase is termed utilization in the context of industrial facilities. It is generally the longest phase of the lifecycle. “Disposal” is the last phase and corresponds to the “demolition” of the facility. If the facility is neither reused nor demolished, the industrial facility lies idle. This state, however, does not preclude later reuse or demolition. With a supply-oriented revitalization, the idle factory can meet the requirements of a new operator and create the basis for a re-run of the cycle [2]. The application of the general product lifecycle in accordance with DIN to the special case of the industrial facility is shown in Figure 2.

The term “cycle” is particularly apt for a building, as, compared to other products, industrial facilities rarely tend to be disposed of/demolished on account of their high value and their long potential use. On the contrary, industrial facilities are used over many lifecycles of the products manufactured in them so that the facilities tend to be reused instead of being demolished. With this subsequent use, the lifecycle is re-run. With the frequency of the reuse, particularly the importance of adaptability increases, as this has a key influence on the financial cost and planning required for reuse. While usually only the lifecycle of a single product is considered, in the design and realization of an industrial building, both the lifecycle of the building and the lifecycle of the production taking place in it have to be analyzed. As shown in Figure 3, future-oriented industrial building must be in a position to enable as many production lifecycles as possible with a high utilization value of the building. This can be achieved particularly with improved adaptability [8].

Depending on the application and available adaptability, the first phases, design and realization, can be much shorter in the re-run of the lifecycle. In the case of an industrial facility designed and realized with a high degree of adaptability in its first lifecycle, far fewer modifications are necessary for efficient reuse. The importance of lifecycle-oriented design for industrial facilities is therefore very high as the initial design determines, in addition to the ownership costs, the costs and duration of later design and realization phases for possible reuses.

With the ever shorter lifecycles of the products manufactured in a factory, this aspect gains increasing relevance. Adaptability, however, should not be forced without analysis of the resulting lifecycle costs.

5 Lifecycle costs

The lifecycle costs are the “accumulated costs of a product over its lifecycle”. They include costs for procurement, ownership and disposal [1]. As a part of the procurement costs, a percentage of costs is included for the development of concept and design or in the case of the industrial facility for the design and planning. In contrast to most products, an industrial building is generally only built once. The design costs cannot be allocated across a large number of units and have a major influence on the procurement costs.

The procurement costs can be calculated simply and are usually stated directly. The main part of the lifecycle costs is in many cases made up by the cost of ownership [1]. Industrial facilities have a particularly long lifecycle and considerable operating costs are incurred, so that the costs of ownership soon exceed the procurement costs.

A holistic study of the lifecycle costs is already needed in the early phase of design, to prevent one-sided optimization of the costs for procurement, ownership or disposal. The lifecycle costs should serve prior to the realization as a characteristic figure for the comparison and optimization of various facility concepts [3].

Lifecycle costs can relate to different levels. For example, the lifecycle costs can be analyzed for an entire building complex with several production shops and administration buildings or just for parts of the building equipment like, for example, the flooring or the façade. For lifecycle-oriented design of industrial facilities, analysis of these individual levels is necessary as the details of the realization have a major influence on the later costs. For example, the building utilization, the bearing structure, the building envelope, and the technical equipment are key factors influencing the lifecycle costs [3].

With the higher initial investment, the costs for the utilization of the building can be generally reduced. However, with oversizing and the additional cost of unsuitable safety margins, the utilization costs can rise even despite high initial investment. The relationships are shown clearly in Figure 4, however, only one single lifecycle with constant conditions is analyzed, the dynamics of the economic environment are not taken into account. For instance, oversized areas may be unnecessary at the beginning of the lifecycle, but at a later point in time can serve as the basis for increasing production capacity. The volatile environment necessitates the reservation of areas for expansion and to enable adaption of the technical equipment of the building to changed conditions.

It is true that other types of building are subject to changing conditions. In industrial facility construction, however, specific restrictions exist as a result of the need for the optimal design of the material flow and the technical requirements of the production processes to be met by the facility. Adaptability is a long-term competitive factor for industrial facilities. For this reason, in the design of an industrial facility, the change costs must be taken into consideration, so that they are not incorrectly assessed as unnecessary initial investment.

The change costs consist of the change object and the change process costs. The change object costs comprise all non-recurring costs in the realization of the industrial facility that enable improved adaptability. All costs incurred directly or indirectly for a later adaption of the building are termed change process costs. In comparison with conventional low-adaptability buildings, for adaptable industrial facilities, around 10 % higher initial investment is assumed on account of the change object costs. This additional investment at the beginning of the lifecycle reduces the change process costs during use of the building. In the design of an industrial facility, it is therefore necessary to minimize the change object and change process costs. In contrast to the non-recurring change object cost, the change process costs can, however, only be forecast as they depend on the future requirements to be met by the building [8].

Often, however, companies demand a very short payback period for investments, so only rarely is the total expected lifetime of a change object taken into account in the calculation of the lifecycle costs [8].

6 Conclusions

The changing conditions in the economic environment demand continuous adaption. This not only applies to the business processes or manufacturing plants but especially the industrial facility too. Adaptability can be ensured with appropriate parameters such as scalability or modularity. For future-viable industrial facility construction therefore, besides the initial design and realization costs, the operating costs (costs of ownership) and especially the change costs must be considered in the scope of lifecycle cost analysis.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Change enablers [7]](https://www.zkg-online.info/imgs/tok_6c0cb821e57cffa3846927758466220d/w300_h200_x306_y396_101545511_e7749d1723.jpg)

![3 Lifecycle of building and product based on [9]](https://www.zkg-online.info/imgs/tok_b9365a60beed0e48e404126552015eec/w300_h200_x353_y288_101545530_4da3085488.jpg)

![4 Relationship of initial investment and usage costs based on [3]](https://www.zkg-online.info/imgs/tok_d2ea6123e608b18680600925b2fa8b39/w300_h200_x400_y272_101545524_e4ac785cfc.jpg)