Innovative technology eliminates carryback on cement grinding conveyor

In the face of this issue, a cement grinding facility in the Carbon Works neighborhood of Detroit discovered a way to virtually eliminate the issue of tacky carryback on one of the plant’s raw material transport conveyors.

1 Introduction

The problem of carryback clinging to the return side of conveyor belts is an ongoing battle for many industries that depend on efficient bulk handling. Carryback and subsequent accumulation interfere with plant operations and expose personnel to unnecessary safety risks while cleaning up the material in close proximity to a moving conveyor. Fugitive material also represents a loss of usable product, which is particularly expensive if it has undergone any level of processing before the spill points.

Carryback can also lead to spillage along the entire conveying system and foul...

1 Introduction

The problem of carryback clinging to the return side of conveyor belts is an ongoing battle for many industries that depend on efficient bulk handling. Carryback and subsequent accumulation interfere with plant operations and expose personnel to unnecessary safety risks while cleaning up the material in close proximity to a moving conveyor. Fugitive material also represents a loss of usable product, which is particularly expensive if it has undergone any level of processing before the spill points.

Carryback can also lead to spillage along the entire conveying system and foul rolling components, with extra cleaning and maintenance raising the cost of operation.

2 St Marys Cement

St Marys Cement, a subsidiary of Votorantim Cimentos, is headquartered in Toronto, Canada, but has operations throughout the Great Lakes region. The Detroit plant produces 200 to 250 t/h (181 to 226 mt/h) of Portland cement and CemPlus, a chemical-resistant dry cement additive. With 15 tall silos at the Fisher Freeway crossing of the Rouge River, the plant provides premixed ground material for transport to other St Marys cement plants, directly to construction sites or to a nearby bagging facility, where it is packaged for sale.

“We’re one of the smaller and more specialized plants in the company, so we have no kiln or concrete production on site,” explained David Accomando, Plant Maintenance Supervisor for St Marys Detroit. “It‘s efficiently run by a central control hub, and maintained by a small and dedicated crew that keeps the conveyors and other systems working at near maximum capacity.”

One of these systems is the covered #14 conveyor. Front loaders transfer dusty 1.5 to 2 inch (38 to 50 mm) minus limestone and gypsum aggregate from massive storage piles located along the riverfront into an 8-foot-long vibrating trapezoidal chute that is flush with the ground at the top. Set at a 35-degree angle leading to the underground conveyor, the chute discharges directly onto the 30-inch-wide belt. Inclined approximately 20 degrees at the point of loading, the #14 belt conveys cargo for 20 feet up to ground level, moves horizontally for 200 feet (61 m), then begins another long 30 degree incline into the top of a 50 foot tall tower. The conveyor discharge zone, with only enough room to fit one primary cleaning blade, offloads into a chute leading to the #11 conveyor, which proceeds to the grinder.

3 Discharge Zone Design and Carryback

Roughly 30000 t (27215 mt) of raw material and clinker arrives weekly by truck and ship. The clinker is housed in a large shelter, while the raw aggregate is offloaded to an outdoor storage area, where the material tends to get saturated when the Michigan weather turns wet and cold. This causes large amounts of mud and sludge to be loaded along with aggregate into the chute leading to the #14 belt. Even though the conveyor system is partially covered with a hood along the entire belt path, cargo is still exposed to weather conditions and can dampen further on its way to the discharge zone.

Operators found that polyurethane cleaner blades were unable to completely clean the belt. “The fines and mud take on the tacky consistency of toothpaste, causing it to cling to the belt along with smaller pieces of aggregate and shale,” Accomando said. “This led to a lot of carryback spilled along the return path, where it fouled idlers and built up so high on the pan under the loading zone that it would encapsulate the tail pulley.”

Maintenance technicians periodically had to stop other essential duties and shut down the system to replace frozen return idlers and prevent further damage. After digging out the tail pulley, workers needed to clean the face, which often had abrasive buildup that could reduce the belt life. In addition, 2 to 3 workers spent up to 8 hours twice per month to clean the loading zone and the belt path using shovels and a vacuum truck.

To manage the carryback at the discharge zone, workers would need to hose down and hammer off buildup from the belt scraper, as well as clean off the face of the head pulley, which was described as acting like sand paper against the belt. The cleaner required regular tensioning and periodically needed to be removed, re-cut and shaped. Despite meticulous care of the blade, it needed replacement two or three times per year.

“All of the cleaning and maintenance was causing unscheduled downtime, burdening our crew and having an impact on operational costs,” said Accomando. “A big concern of ours was buildup around the loading zone and the tail pulley, which was affecting belt life and causing a safety issue. We needed a solution.”

4 Trickledown

Loading onto a sloped belt can be challenging, but with a well-designed transfer system, a controlled incline and an adequate settling zone, there should be minimal spillage. However, without effective belt cleaning, carryback on an inclined belt can create problems all the way back to the tail pulley.

“Buildup of dust, fines and wet sludge fouling the face of the tail pulley leads to several issues that have costly consequences on the entire conveying system,” said Jason Haynes, Territory Manager for Martin Engineering.

Pulley slippage can affect the belt speed and cause abrasion damage on the return side of the belt. Larger pieces of aggregate can migrate to the bottom side and get trapped between the belt and the tail pulley. The force of pressure on these rocks caught between the belt and the pulley can gouge the face, drop it back onto the belt, and cycle it through over and over, further causing damage.

“A fouled and gouged tail pulley can cause the belt to wander as it enters into the loading zone, so cargo loads unevenly and creates spillage along the belt path,” Haynes added. “No matter how well you design the loading and settling zone on sloped conveyors, without a good cleaner at the discharge point, the cleanup and equipment replacement costs from carryback can quickly derail the benefits of your loading zone improvements.”

5 Testing new belt cleaning technology

Having built a relationship with Martin Engineering and a familiarity with the manufacturer’s products, many of which are placed throughout the plant, Accomando contacted Haynes to provide a solution. Haynes examined the system by performing a meticulous Walk the Belt procedure, and creating a checklist of potential causes and effects of the carryback issue.

Haynes concluded that the #14 conveyor was an excellent candidate for the company’s CleanScrape Primary Cleaner. A new innovation in cleaning technology, the cleaner was a good fit because it requires considerably less space than other primary cleaners. Yet in the right applications, it can be effective enough to eliminate the need for a secondary blade, and the unique design has been proven to deliver as much as 4x the lifespan of competing urethane blades.

Choosing a free 30-day trial to test whether the cleaner was right for the job, the plant scheduled the installation to coincide with downtime for other maintenance. Two Martin Engineering technicians completed all the necessary fabrication and had the unit ready to be placed into service within a day.

6 Innovative design

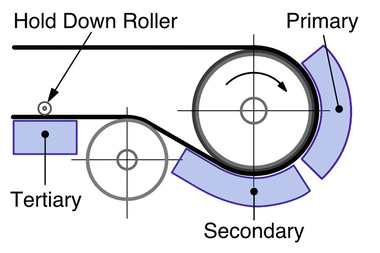

There are many traits that separate the CleanScrape design from conventional urethane blade cleaners. Mounted using an upper and lower chain configuration attached to a Cleaner Tensioner Diverter, the surface spans the entire belt profile. The flexible cleaner is installed diagonally across the discharge pulley, forming a three-dimensional curve beneath the discharge area that conforms to the pulley’s shape.

The unique design incorporates a matrix of tungsten carbide teeth and is tensioned lightly against the belt to prevent damage to the belt or splices. Despite extremely low contact pressure between belt and cleaner, it has been shown to remove as much as 95 % of potential carryback material. The low pressure allows the blade to pass over the #14 conveyor’s vulcanized splice without damaging the belt or splice.

Designed for belt speeds up to 780 fpm (4 m/s) for mechanically spliced belts, pulley diameters up to 50 inches (1270 mm), and belt widths up to 96 inches (2438 mm), the CleanScrape is engineered to perform under the punishing conditions of the cement and bulk handling industries. Unlike other cleaners with a rigid mandrel, bulky tensioner or an unwieldy blade section, the dual chain mounting has a significantly lower installation footprint on the mainframe and a user-friendly design for adjustment, service and replacement, without confined space entry.

Suitable for reversing belts, the CleanScrape is equipped with two breakaway links, allowing the operator side of the cleaner to separate from the tensioners and fall away from the belt. Remaining attached to the far side bracket, this important safety feature prevents damage to the cleaner or conveyor components, so that operators can shut down the system and safely replace the cleaner with minimal downtime.

Perhaps its most valuable feature is the extremely low maintenance it requires. The tensioners are tightened during initial installation and then re-tensioned about a week later. No further adjustment is required over the life of the blade. As the tungsten cleaning surface wears in the direction of belt travel, the cleaner is supported at right angles to the belt, so the wear of the tungsten has no effect on the tension being applied.

“Customers see a real savings from not having to adjust the belts,” said Haynes. “It’s considered nuisance work, and most maintenance people focus on other things instead of cleaners. This results in carryback. And it takes a huge toll on production. Let’s say a plant is down for one day a week for scheduled maintenance, or four days a month. Many operators I’ve spoken to have said that at least one of those four days will essentially be belt cleaner day – that is, 25 % of maintenance activities on belts is adjusting cleaners. So if they can get back 25 % of that maintenance time – plus the lost production – the potential savings are astronomical. It could be tens of thousands or even hundreds of thousands of dollars a year.”

7 Results

With the cleaner system ready for a fresh test, the results were apparent almost immediately. As cargo with a moisture level of 10 to 15 % was loaded onto the belt, dust and fines built up into a thick paste as usual, but ended up being fully removed from the belt. After the 30 day trial was concluded, operators discovered the cleaner to be so efficient that it extracted more material than the chute could process, causing it to build up in the chute and back up onto the blade. To address the increased volume of discharge, Martin Engineering technicians returned and installed a Vibrating Dribble Chute to enhance the flow capability of the discharge zone.

“For this application, we were very surprised by how well it worked,” Accomando said. “The return side of the belt might have a little bit of wet material still on it, but nothing even remotely close to what it used to be. This has eliminated the problems we previously had with buildup around the tail pulley and fouling of the head pulley, meaning the belt life has definitely improved.”

After a full year of punishing 24/7 operation with little downtime through conditions that included cold slush and mud, as well as hot and dry dusty material, the original cleaner continues to perform consistently well, without a single adjustment. The cleaning schedule has been altered from a 2 to 3 person crew over a full shift twice per month, to just a single worker hosing down critical areas for an hour or so, once per month.

“We haven’t touched the blade or tensioner once since they were installed a year ago,” Accomando pointed out. “That’s one of the great things about working with Martin, not only is their equipment top notch, but what stands out most to me is the service. They make sure it is installed properly and then follow up regularly to make sure that we’re happy with the product, and we are.”

//www.martin-eng.com" target="_blank" >www.martin-eng.com:www.martin-eng.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.