High performance has a name

The British waste management company Premier Waste UK PLC has always been among the industry’s pioneers. It produces high-quality alternative fuels for main burners from pre-shredded extraneous-matter-free construction site waste, consisting of paper, plastics, packaging materials, textiles, wood and similar combustibles.

Premier Waste decided as long ago as 2008 to install a Lindner-Recyclingtech secondary shredder, since Lindner machines even then set the standard for high-quality, high-performance shredders. The KOMET 2800, with its throughput rate of 12 t/h and granulate particle size of <...

The British waste management company Premier Waste UK PLC has always been among the industry’s pioneers. It produces high-quality alternative fuels for main burners from pre-shredded extraneous-matter-free construction site waste, consisting of paper, plastics, packaging materials, textiles, wood and similar combustibles.

Premier Waste decided as long ago as 2008 to install a Lindner-Recyclingtech secondary shredder, since Lindner machines even then set the standard for high-quality, high-performance shredders. The KOMET 2800, with its throughput rate of 12 t/h and granulate particle size of < 30 mm performed excellently and with great reliability for five years and 36,000 hours of service. Unfortunately, this machine was written off in a disastrous fire in 2013. The good operational experience and the knowledge gained concerning the quality of this shredder nonetheless meant that only another KOMET could be considered when the time came for expansion of PW’s production.

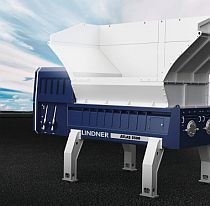

Around one month later, Premier Waste’s Head of Production, Mark Jones, took the opportunity at the RWM trade fair of obtaining detailed information from MachTech Services, the well-established Lindner agency for the UK and Ireland, on the latest, high performance edition of the KOMET range. The decision to replace the fire-damaged KOMET 2800 with the machine on show at the fair, a KOMET 2200 HP (Fig. 1), was taken virtually on-the-spot.

This new KOMET model from Lindner convinces not only with its 50 % higher throughput compared to competing shredders, but also, and above all, with its reliability and the track record of previous Lindner machines. The final impulse for this purchase was provided by the new machine’s compact size and footprint, combined with even greater productivity, short delivery-times, still better specific performance data and Lindner’s tried-and-proven support services.

Like all Lindner-Recyclingtech machines, the KOMET 2200 HP is tailored to the user’s specific requirements. The input material was stated as pre-shredded lights free of extraneous matter from construction site waste (Fig. 2) with a bulk density of around 150 kg/m3 and a residual moisture content of below 30 %. Premier Waste’s specification was for a 14 t/h throughput at a particle size in the output fraction of 95 % < 30 mm. Lindner-Recyclingtech was able to assure this for the KOMET range of high-performance secondary shredders, and configured the machine correspondingly.

After installation, Lindner-Recyclingtech’s technicians performed a series of on-site tests. The performance trial demonstrated that the machine achieved a throughput rate of just over 20 tonnes per hour, 45 % more than specified, at a standard speed of 355 rpm (Fig. 3). Analysis of the particle size range of the SRF fraction showed that 93 % of the granules were smaller than 20 mm, with 50 % actually smaller than 10 mm. These performance figures attested yet again to Lindner-Recyclingtech’s innovative machine technology and the high quality of the alternative fuel produced.

Mark Jones is a confirmed fan: “This machine gives us six tonnes more output material per hour, on average, than we were expecting – that’s just fantastic! It will cut our operating and energy costs drastically, and boost our production rate significantly.”

The main characteristics of the dependable Lindner machine technology is a simple, maintenance-free belt-drive system, complete with safety coupling, which protects the machine against damage caused, for example, by extraneous matter, standard components available around the globe, and easy maintenance and servicing access.

The precision shredding mechanism (Fig. 4) convinces with its quick-change cutters and counter cutters, which are of identical design, thus minimising spares stocking costs. The KOMET’s shredding gap can be easily adjusted from outside at any time, assuring constant output material quality and high throughputs right up to the end of the cutters’ service life. The machine is preset to the specific material to be processed by means of a “smart” control system, while all process information is displayed on an easily comprehensible touchscreen. Lindner technicians provide trouble-shooting assistance quickly and with no unnecessary formalities, via Internet-based remote maintenance.

Mark Jones is also pleased with MachTech’s on-site service, as well as with the technology. As David Ingham, director of MachTech, summarises: “We are totally knocked out by the results achieved at Premier Waste. This is a customer that sets high standards for the quality of its alternative fuels and therefore also for the technology used. This machine was the first of its type to be installed in the UK, and it really does perform well beyond everyone’s expectations”.

MachTech has supported customers in the United Kingdom and Ireland as the exclusive Lindner-Recyclingtech agency since 2008, and is responsible for around 90 % of all SRF shredders installed in these territories in the past five years. The ISO 9001-certified company has an outstandingly comprehensive service network and also offers its customers tailor-made maintenance and service agreements, a 24-hour service hotline and service technicians optimally trained for servicing of Lindner equipment.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.