Geda industrial lifts at the Märker cement works in Harburg

Two industrial lifts from Geda-Dechentreiter GmbH & Co. KG based in Asbach-Bäumenheim, Bavaria, are providing valuable transportation services to the preheater tower and the multi-chamber silo of the Märker cement works in Harburg.

The lift travels almost 70 m up the preheater tower and the multi-chamber silo of the cement works. However, the Märker employees can only enjoy the beautiful view over the Danube-Ries region for a short time, because their main priority is to reach the different levels quickly and safely round the clock because maintenance work is essential to guarantee a smooth cement production process.

For generations, the company name Märker has symbolised quality and therefore it considers the lift providing a reliable height access solution to access the landings on the preheater tower and on the silo...

The lift travels almost 70 m up the preheater tower and the multi-chamber silo of the cement works. However, the Märker employees can only enjoy the beautiful view over the Danube-Ries region for a short time, because their main priority is to reach the different levels quickly and safely round the clock because maintenance work is essential to guarantee a smooth cement production process.

For generations, the company name Märker has symbolised quality and therefore it considers the lift providing a reliable height access solution to access the landings on the preheater tower and on the silo to be extremely important. Therefore, when selecting its lift technology, the Harburg-based company decided to rely on the many years’ experience and expertise of Geda-Dechentreiter GmbH & Co. KG located in Asbach-Bäumenheim only 20 km away.

For almost nine decades in the construction machinery sector the name Geda has represented competence, safety and quality “Made in Germany” and its product range could not be wider, spanning compact 60 kg wire rope lifts through to 3.7 t personnel and material lifts with lifting heights of up to 400 m. Over the last ten years the industrial lift product range designed for the oil and gas industries, power stations and cement works has been further expanded. Using state-of-the-art engineering, these solutions are designed and produced specifically to meet the needs of customers and their specific locations.

Geda industrial lifts enable efficient maintenance

and winter inspection for cement works

Especially when heights have to be scaled for maintenance and repair works, such as on the preheater tower or on the multi-chamber silo, considerable valuable time is lost along the way in the truest sense of the word, as employees are very often left with no alternative other than an arduous climb up the stairwell to carry tools and other materials. The installation of an industrial lift offers a time-efficient and reliable alternative. During the winter inspection when heavy spare parts as well as tools need to be conveyed upwards, the many benefits of the industrial lifts from Geda quickly become apparent.

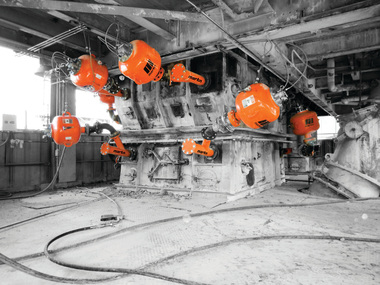

Lift cars with large payloads offer sufficient space for transporting bulky and heavy parts up and down easily and safely. Therefore the Geda SH 2000 industrial lift with its load capacity of 2000 kg respectively 26 people and a lifting speed of 40 m/min is being used on the preheater tower of the Märker cement works and the Geda SH 1000 with its load capacity of 1000 kg respectively 12 people and a lifting speed of 40 m/min is providing efficient and reliable transportation of people and materials up the multi-chamber silo.

The Geda specialists used state-of-the-art engineering techniques to adapt each lift to the specific requirements of the cement works. Therefore the Geda solutions were able to withstand even the toughest environmental conditions such as excessive heat development.

However, the Geda solutions also offer customer-appropriate, temporary height-access solutions in the form of robust transport platforms for people and materials, hoists purely for materials and versatile transport platforms for new cement factory constructions as well as for maintenance and repairs during ongoing operations or during the winter inspections.

Integrated project support approach

The project business in particular relies on good and trustworthy collaboration. Geda has been operating a comprehensive support approach for many years. The company sees itself not only as a supplier but above all as a reliable partner for its customers, with everything being supplied from a single source from the initial enquiry right up to the maintenance and servicing contract. For Geda service does not end with the delivery of the device. On the contrary, Geda provides support during installation and additional acceptance tests on-site, gives advice in service training sessions customised to the product and offers a quick replacement parts service, a repair service and maintenance agreements.

The specialists from Geda are also on hand when it comes to the replacement of ageing lift solutions, since it is often more economical to consider investing in a new device than to purchase expensive spare parts.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.