Energy saving, faster and quieter: servo

motors optimize sand-lime brick presses

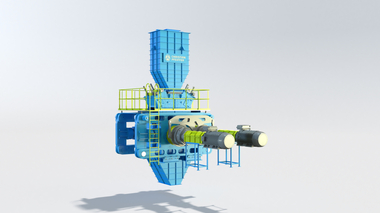

As an alternative to the conventional solution – and at no greater cost – the market leader Masa is equipping its established sand-lime brick presses with hydraulic pumps driven by servo motors. These run only when required by the process, saving up to 35 % of energy, especially for larger products with longer cycle and idle times. This not only enables the presses to work faster, but also considerably more quietly and, as practice has shown, the simplified hydraulic system is easier to maintain.

Sand-lime brick is a building material with many advantages and is widely used across the Benelux countries, Germany, Poland, Ukraine, and as far as Russia. There are various established stone formats - from small and medium standard sizes, to large-format slabs up to 650 mm high and almost one meter wide. These have always been manufactured on hydraulic presses.

In both, technological and commercial terms, Masa GmbH from Porta Westfalica in Germany is one of the leading suppliers of single- and double-sided sand-lime brick presses. Based in Andernach, the company is steeped in tradition. At...

Sand-lime brick is a building material with many advantages and is widely used across the Benelux countries, Germany, Poland, Ukraine, and as far as Russia. There are various established stone formats - from small and medium standard sizes, to large-format slabs up to 650 mm high and almost one meter wide. These have always been manufactured on hydraulic presses.

In both, technological and commercial terms, Masa GmbH from Porta Westfalica in Germany is one of the leading suppliers of single- and double-sided sand-lime brick presses. Based in Andernach, the company is steeped in tradition. At its Westphalian facility in Porta Westfalica the company develops and manufactures everything required for the manufacture of “white products” made of sand-lime brick and autoclaved aerated concrete (AAC). The range of products for the sand-lime brick industry includes machines and plants for the entire production process, ranging from material storage and treatment through pressing, sawing, autoclaving and packing to turnkey plants, including all handling and transport equipment.

For many years, Masa has relied on control technology, and increasingly on (servo) drive technology, from Siemens. The latter was recently a decisive reason why a Dutch producer of sand-lime brick opted for a Masa solution.

Focus on energy and cost savings

The bauma in Munich is the leading world trade fair for machinery used in the construction, building material and mining sectors as well as for construction vehicles and construction equipment. It was here in 2016 that the Dutch company’s attention was drawn to the “servohydraulics”, as the machine builder calls its latest drive concept, whereby they displayed particular interest in the advantages to be had in terms of energy consumption. With the expansion of an existing production facility to include an additional double-sided press, the opportunity soon arose to substantiate these advantages in daily practice. Masa was commissioned to completely modernize an older press of the type HDP 1200 J (Jumbo, with 1200 metric tons of pressing force) brought in from another plant, and to integrate it into the overall process.

The machine builder initiated the “Servohydraulics Project” a good three years ago and since then has already sold several presses using this innovative drive system. The approach is a further development of the tried and tested drive concept, in which compact and dynamic synchronous servo motors from the Siemens Simotics M-1PH8 series replace the existing asynchronous motors on the variable displacement pumps which are already electronically regulated. In this way, the press manufacturer has relocated the intelligence from the pump to the drive. Now either constant-flow or variable displacement pumps can be operated even more precisely according to the actual (oil) demand, which saves further energy. The savings are greater the longer the servo motors can be operated in “zero position”, in other words when the cylinders are at a standstill. Consequently, this happens most frequently for large format products with longer cycle and idle times. This is in contrast to the asynchronous motors, which run the whole time with a basic load of about 10 kW to 15 kW.

Previously, the machine builder realized the necessary pressure peaks in the process by momentary overload operation of the motors. Thanks to the significantly higher overload capability of servo motors, two asynchronous motors with 55 kW each can now be replaced by two Simotics servo motors with a rated power of just 38 kW each. With the shaft height 180 mm (SH180), these offer a very balanced ratio of output, functionality, size and price. The interaction with the converters of the modular Sinamics S120 series and the Simatic S7 300 controller required by the operator is inherently guaranteed by means of system tests at Siemens.

The result is a reduced consumption of energy by the double-sided Jumbo press of up to 35 %, as shown by measurements in regular productive operation. In the case of small and medium-format products, savings of up to 20 % are possible, as the experience of the machine builder from other projects has shown. “Bearing in mind that this is always in comparison with the latest generation of drives with the latest variable control pump technology, not with historical solutions,” emphasizes Design Manager Werner Baumann.

As pressure and volume flow are now regulated exclusively by the motor speed, conventional proportional valves are no longer required, which simplifies both maintenance and the stocking of spare parts. Simplified valve technology also reduces the friction and shear strain of the oil, and consequently the oil temperature. This in turn will delay the aging of the oil and extend the oil change intervals. And because it has been possible to reduce the quantity of oil in the HDP 1200 J by more than 1000 l, significantly less cooling is required overall. Both these facts reduce the operating costs even further.

Higher output at maximum quality –

and no extra cost

The large double-sided press with a traversing distance of the lower press of just about 1000 mm now achieves ram speeds of up to 750 mm/s in the upward movement. The upper stamp moves downward at a similar speed and compacts the material further to the required final dimensions and required bulk density. After release, the lower stamp pushes the finished elements out in an upward direction, where the unloading apparatus takes over.

The stacking system has also been decoupled from the conventional hydraulics and converted to servo hydraulic drive. In this way, the semi-finished bricks can be stacked on top of one another with greater precision and significantly less use of energy, supporting a faster sequence that also protects the products. All in all, the new approach reduces cycle times in the production of large slabs from the previous 60 to 70 s to about 40 s without any loss of quality.

The significantly improved speed constancy of the servo motors also minimizes fluctuations in quality. Furthermore, thanks to the servo drive technology, the two hydraulic main axes (lower and upper press) can be operated either in combination or completely separately, permitting more flexible motions that can be adjusted to the behavior of individual materials. On the Simatic operator panel, the operator can intervene in the process at any time, respond quickly if there is a fluctuation in material properties, and maintain a high product quality.

One significant side effect is the noticeably lower noise emission from the servo driven hydraulic units, “so that you actually have to look inside to see whether the press is running” according to Sales Manager Matthias Klare. One immediate advantage is that sound insulation is no longer necessary, which in turn saves time, and thus money, during construction and commissioning. “All in all, we can offer presses with servo hydraulics at no additional cost”.

The servo drive technology from Siemens has proved itself, among other things, in the subsequent sawing process, where well over 40 Simotics motors now ensure fast, precisely coordinated processes.

Retrofit packages assembled

As a matter of principle, Masa equips its sand-lime brick presses with the control and drive technology requested by the user, so that the latter has the choice between maximum continuity and the new quieter, more energy efficient, productive, and more maintenance-friendly solution driven by servo motors. With standardized retrofit packages, it is even possible to retrofit earlier generations of presses quickly and easily with servo hydraulics and the necessary control functionality. These packages are aligned with the HDP 800 and HDP 1200 series of presses in all their variants.

On course for further innovation

With the servo hydraulic system, Masa meets the requirement of many operators for competitive solutions for sand-lime brick production. The next planned stage of innovation is a changeover to the latest Simatic S7-1500 generation of controllers from Siemens. This will bring the operators in line with a future-proof state of the art for many years to come, also in terms of PLC.

Those responsible at Masa decided unanimously for the servo drive solution from Siemens because comprehensive support was offered from the start. This started with consultation and the selection of the motors and converters, and extended to the commissioning carried out by drive specialists from Bielefeld. Further reasons were the inherently optimized interaction of the control and drive system and the openness toward a variety of hydraulic units. In this way, the operators themselves can continue to program and modify the tried and tested positioning implemented in the PLC. With most enclosed, black-box solutions from other suppliers this would no longer have been possible and would have had a detrimental effect on servicing capability. The conclusion was that, all in all, Siemens offered the best overall package.

Like all other operators, the Dutch operator of the Masa Jumbo Press with its servo hydraulic system is satisfied in every respect with the progress of the project as well as with the operating results.

//www.siemens.com" target="_blank" >www.siemens.com:www.siemens.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.