Coordinated – Single-source supplier for hot environment

Our world can be hardly imagined without the product ‘lime‘, and due to its application in environmental protection, it has virtually become ubiquitous to anyone. Quality demands, the variety of available lime products and, above all, the environmental restrictions for production sites have increased significantly and will continue to do so. For the factories, this means continuous optimization of processes and the necessary auxiliary circuits as well as further investments in new firing technology. As a consequence, automation requires the reliable recording of measured values with narrower tolerances.

In the lime production process, measurement technology for the measuring of filling levels, flow rates, pressure, temperature and for analytical purposes is required in varying quantities and of unequal importance. The basic requirements for safe plant operation concern all measuring instruments:

Reliable physical measurement principles

Robust technology

Easy handling of field devices

The environmental conditions in the lime works are harsh: sunshine, wind, rain, dust, heat, cold and partly even vibrations exert a constant influence on the devices. In this ambience, measuring technology from...

In the lime production process, measurement technology for the measuring of filling levels, flow rates, pressure, temperature and for analytical purposes is required in varying quantities and of unequal importance. The basic requirements for safe plant operation concern all measuring instruments:

Reliable physical measurement principles

Robust technology

Easy handling of field devices

The environmental conditions in the lime works are harsh: sunshine, wind, rain, dust, heat, cold and partly even vibrations exert a constant influence on the devices. In this ambience, measuring technology from Endress+Hauser has proven its worth in continuous operation at most different operation sites, as the following examples show:

At the furnace (Figure 1) - which is the core of the manufacturing process - temperature and pressure sensors as well as flow meters and level gauges are required for the control system. As energy for the calcination of the natural carbon dioxide is supplied in the furnace, temperature measurements are of vital importance with regard to the monitoring of the process in the individual zones. In the lime works of Istein in the South of Baden, the various furnace temperatures at the new furnace are measured using Omnigrad S type thermometers from Endress+Hauser. The instruments are installed at the decisive points of the furnace, as for example at the transfer port (Figure 2) and at different levels of the double shaft furnace.

In these applications, the operating temperatures are partly significantly above 800 °C. In most cases, abrasion and aggressive gases exist in addition to the mere stress caused by heat. Under these external conditions, the materials of the protection tubes and thermocouples are brought to their limits.

In recent years, materials research has created a lot of new materials - both metal alloys and ceramic substances. Endress+Hauser implemented the results of the research work in the high-temperature series TAF. The broad range of thermometers of the Omnigrad series ensures optimum temperature measuring in any application. In the new double shaft furnace in Istein, for example, the Omnigrad types TAR16 and TC 65 are used (Figure 2).

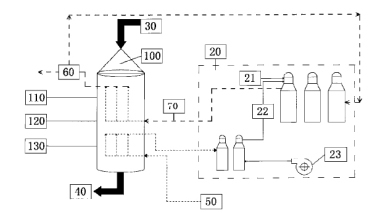

To ensure the firing process and the quality of the lime, the pneumatic dosing of the solid fuel has to be monitored as well. In order for the values to be comparable under any operating condition, it is necessary to measure the gas volume flow of the pneumatic system in standard volumes (Figure 3). Here, the measuring section consists of a flow meter according to the Vortex principle, a pressure sensor and a temperature sensor. The additional information about the current pressure and temperature condition enables the conversion of the conveying compressed air into the standardized volume flow in Nm³/h.

In these ambient conditions, the ceramic measuring cell of the pressure sensor, which provides up to 40 times the overload resistance, has proven to be highly efficient. Equipped with measuring membranes made of ceramic, the pressure transmitters Cerabar S and Cerabar M are also suitable for media with high abrasive solids content. Here, in the lime works, the Cerabar S PMC71 was installed in the pressure line to obtain long-term stable pressure data even under such demanding conditions.

The operating concept with three-button-operation is the same as that of the flow meter according to the vortex principle (Fig. 4); it enables a simple and reliable startup. All settings and queries can be comfortably carried out from outside and thus without interventions in the measuring instrument. Moreover, using the data storage unit HistoROM/M-DAT, the device configuration can be duplicated quickly and safely by replugging the module to other measuring devices. As the housing can be turned by 380° irrespective of the process connection, the pressure transmitter adapts to any process environment.

The flow meter from the Prowirl family installed next to it, which operates according to the Vortex principle, ensures long-term stable continuous operation at high pressure and temperature resistance and constant flow measuring accuracy. In contrast to conventional piezo-based vortex flow sensors, the balanced DSC sensor (Differential Switched Capacitance) provides high vibration resistance, which is important for pneumatic conveyance with partially varying loads, changing product properties and the pressure fluctuations associated with it.

Similar to a flag, the sensor paddle extending into the pipeline is deflected by the vortices emerging at the damming device. As a result, the distance between the central electrode and the outer electrode changes. The evaluation electronic counts the number of capacity changes. This procedure is both reliable and precise. The maximum measurement error is +/- 1 % of the current value for gases. Moreover, humidity or impurities at the front of the damming device have a rather negligible influence on the measuring result.

Thus, with the temperature measurement instrument Omnirad S in the pipeline, it is possible to calculate the standard volume at any time. The resistance thermometer Omnigrad is perfectly suitable for demanding and safety-related measurements. This measuring instrument is used in explosive areas, here in coal dust dosing to the furnace. The clamping device enables the quick installation or potential exchange of the device.

In the bulk processing industry, and not only there, the operator has to handle increasingly more tasks, besides production monitoring. The staff responsible for electrical engineering provides for the smooth automation of the plant and has to look after the power supply, the various frequency converters of the driving station, the sensors and the intra-plant communications technology.

For this reason, simple operability becomes a decisive factor in the selection of a product. Intuitive, standardized operation provides security of performance and reduces cost and efforts. Endress+Hauser implements this by standardizing device operations across product families and measuring values. The new two-wire instruments used in the fields of filling level and flow rate measuring are characterized by consistency in the following aspects:

Control elements on-site, interface for the parametrization via Common Data Interface (CDI), parametrization software FieldCare according to DTM standard, control menu with three user groups: plant operator, maintenance staff and experts/service. This reduces complexity for the user while simplifying daily work routine.

However, besides choosing the best measuring principle and the optimally adapted technology, it is their correct installation that is decisive for permanently reliable data acquisition. The rapid and uncomplicated startup by means of a quick setup at the measuring device reduces time and costs for the operator.

“Profitability analyses go beyond measuring devices”, says Rudolf Eichin, Head of the Technical Office and responsible for energy management at the lime works Istein. “Due to the standardized and simple operation, startup time and training measures can be reduced to a minimum”, the project manager continues. “With the universally suitable components, inventories and spare parts stock will be minimized.”

More and more customers appreciate Endress+Hauser as a turn-key supplier offering the complete range of services for the bulk processing industry, ranging from the comprehensive field instrumentation and services up to automation solutions and appealing Life Cycle Management. All appliances, components and systems are exactly adjusted and work in perfect harmony. The advantages hiding behind the key word “turn-key supplier” are obvious: one partner who supplies everything from one source, provides multifaceted added value to all business processes.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.