Controlling FGD gypsum moisture online

The E.ON “MPP3” is the most modern and biggest hard coal fired power plant in Rotterdam-Maasvlakte/Netherlands with the notable gross power rating of net 1070 MW and a net efficiency of over 46 % (Fig. 1). The plant produces steam with very high conditions (285 bar, 600-620 ˚C) by using pulverized coal. The steam is converted to power by a turbine and a generator. The “MPP3” is intended to reduce the effects on the environment as much as possible.

One step to achieve the environmentally friendly process is the optimisation of the flue gas desulphurization (FGD) unit. The desulphurization is...

The E.ON “MPP3” is the most modern and biggest hard coal fired power plant in Rotterdam-Maasvlakte/Netherlands with the notable gross power rating of net 1070 MW and a net efficiency of over 46 % (Fig. 1). The plant produces steam with very high conditions (285 bar, 600-620 ˚C) by using pulverized coal. The steam is converted to power by a turbine and a generator. The “MPP3” is intended to reduce the effects on the environment as much as possible.

One step to achieve the environmentally friendly process is the optimisation of the flue gas desulphurization (FGD) unit. The desulphurization is done by a wet flue gas cleaning unit controlled by a moisture measurement. This flue gas desulphurisation is so far more effective than in other traditional coal fired power plants. Beyond others, the “MPP3” can achieve a thermal substitution rate of up to 30 % by co-combustion of biomass. And, of course adjacent companies use its heat by district heating.

General description of the process

The desulphurisation is based on the reactant of burnt lime (CaO) which end product is FGD gypsum (calcium sulfate dihydrate). For the required quality assurance and analysis of the produced gypsum an in-house laboratory is located in Rotterdam-Maasvlakte. This in-house laboratory evaluates all the recurrent samples that have to be taken to control the moisture content of the gypsum. The FGD gypsum is only tradable and feasible for further processes with a moisture content of approximately 10%. Based on this value a continuous measuring and storage of the actual moisture content is indispensable. To avoid clogging and deposits during the whole process and to guarantee the best flow characteristics in all following transport systems, a moisture measurement system is very reasonable.

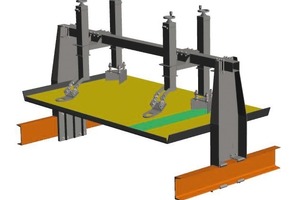

In the “MPP3” FGD plant the moisture values are served by an online–measuring system at the vacuum band filter. The two sensors are mounted in the individually developed over belt construction from ACO (Fig. 2). This solution is very important to reach a successful and reproducible result of the moisture measurement. The digital signal is available without any delay. It is very easy to implement the signal to the plant control via Profibus DP or an Analogue-Output (4mA…20mA).

Description of the ACO moisture

measurement system

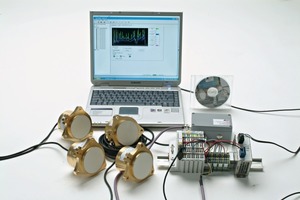

The power plant has decided to use the digital moisture measurement system from ACO automation components. The measuring principle is based on a capacity measurement method (high frequency-dielectric shift, f = 0.02 GHz). The Profibus DP interface allows the communication between the evaluation unit and the process control system of the power plant (Fig. 3). The traditional communication via analogue signal (4 mA…20 mA) is also available. With the help of the measured data of moisture the drying process is controlled and managed. The calibration was made via ACO-calibration software. It has to be done only once each time with less installation costs and the system is able to replace a sensor without the necessity to repeat the calibration, which reduces downtime costs, as well.

If further sensors are required the evaluation unit can handle up to 16 additional sensors. Each sensor is able to measure 16 different materials of additional product, if necessary. A penetration depth of approximately 150 mm depending on the material can be reached. The sensor has a long lasting robust golden hosing, like almost every sensor of ACO (Fig. 4).

Individual execution of the sensor installation

One of the most important things for moisture measurement is the mounting condition of the sensor. A constant material height and density should be given. To guarantee such optimal process conditions a special scraper is installed in front of the sensor. Furthermore the sensor is mounted on a sledge. This also improves the surface of the material and reduces material deposit in front of the sensor. Via a hand wheel the material height and the sensor position is adjustable very fast and easily (Fig. 5).

Prior experiences with ACO have shown that only one sensor on a 2.4 meter wide belt is not sufficient for an accurate moisture measurement, due to this the moisture measurement device consist of two sensors minimum (Fig. 6). On the one hand the reproducibility of data is higher and on the other hand the function of the sealing lip can be monitored as a safety function. In the case of any damages the vacuum and consequently the drying process will not work as well as required. In that case, when one sensor measures increasingly higher moisture values obviously the sealing lip has to be replaced.

The whole over belt construction is made out of stainless steel. Every evaluation unit is separated in its own control cabinet. It is possible to integrate the evaluation unit in already existing control cabinets at the plant. This equipment also helps to reduce the fluctuations of moisture supply in the grinding of cement with FGD gypsum.

//www.acoweb.de" target="_blank" >www.acoweb.de:www.acoweb.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.