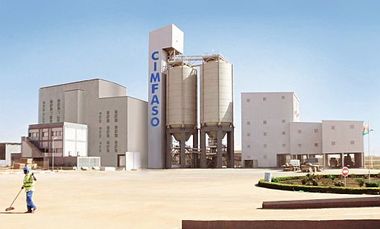

Cement plant of the future

Intelligent linkage of technologies to form a highly-efficient processZKG International were given the opportunity to participate in a workshop talk at Haver & Boecker OHG with Florian Festge, Managing Partner, Bernhard Pagenkemper, Director Global Sales, and Wolfgang Bednarz, General Manager Business Unit Cement, to talk about developments in the Cement Division.

BEDNARZ: In the cement factory of the future a Haver & Boecker system will be the core equipment of the packaging plant, and will be closely interlinked with the upstream and downstream process stages.

PAGENKEMPER: We cover the...

ZKG International were given the opportunity to participate in a workshop talk at Haver & Boecker OHG with Florian Festge, Managing Partner, Bernhard Pagenkemper, Director Global Sales, and Wolfgang Bednarz, General Manager Business Unit Cement, to talk about developments in the Cement Division.

BEDNARZ: In the cement factory of the future a Haver & Boecker system will be the core equipment of the packaging plant, and will be closely interlinked with the upstream and downstream process stages.

PAGENKEMPER: We cover the entire process chain: processing, storage, mixing, packing, filling, palletizing and loading. We do not just supply individual technologies, but also analyse the entire system structure of our customers in order to develop and implement customized system solutions from a single source. We undertake the project management from detailed planning, to the civil engineering and onward to the plant commissioning – and if required we even operate the plant. Our aim is to reach every point within the customers’ universe.

FESTGE: And it doesn’t matter whether the customer fills the material into PE bags or paper bags – or what size of bag is involved. We accept the challenges posed by customers.

BEDNARZ: That would be good – certainly, bags with capacities of 12.5 kg, 25 kg, 33 kg, etc. are available, but cement is still mostly shipped in 50 kg bags. However, it was only the increasing importance of occupational health and safety that led to the use of lighter bags in Germany and Europe. Haver & Boecker was motivated by a particular customer to enable the filling of cement into smaller PE bags, and we were able to follow this request because our company already possessed the relevant expertise! We observe how these trends are becoming stronger, and consequently form our vision of the cement plant of the future: The client has a need for optimization and constantly searches for solutions; specifically for system solutions and not just for “more favourable” equipment or plant sections. Haver & Boecker intends to orientate our developments far more strongly to actual customer requirements – as we did, for example, in the case of PE bags.

FESTGE: It was also a customer request that prompted us to respond to the challenge of filling powdery material into PE bags. The special motivation here is that the PE bag has the potential to eliminate the seasonality of production in the cement industry. By offering the possibility of long product storage periods, even outdoors, the PE bag provides a way of inexpensively operating a storage area without having to use permanent buildings. The cement can be stored or shipped to suit demand variations. The production process can run continuously and the storage area serves as a “buffer”. For an African customer, we recently calculated just what it would mean if he could continue production throughout the rainy season. The resultant financial bonus was enormous. But for us there will be no fundamental conflict between the usage of paper or plastic bags. Each type of bag has its merits. We have experience with both types in different industries and can transfer this experience to others in order to suit any plans that the customer may have.

PAGENKEMPER: The entire production process only works cost effectively if excellent interoperation of all the processes is achieved; in other words, if they are automated. This means that the customer only needs to control and monitor the systems. Intelligent automation enables the customer to act in a needs-based manner.

BEDNARZ: In our opinion, it is certainly important to install the latest technology everywhere in the world. Even in the remotest areas, our technology enables us to help with automation and remote access to systems. Especially in emerging markets, our technology’s suitability for daily use becomes clear when difficulties occur or something is unclear. In such situations, the customer still has the security that he needs. In regions of the world where personnel training is not of the best standard, we can look into the process using our remote maintenance system and provide immediate online assistance.

PAGENKEMPER: Education and training are the keywords for the future. Education provides the prerequisite for plant automation and, consequently for cost effective production, two things which are mutually dependent! The degree of automation in the packing department will increase. The educational level of workers will also increase and thus they will take on higher-value tasks such as controlling and monitoring the entire plant.

FESTGE: That’s how we see the future … – or better expressed, Haver & Boecker is developing the future! We have very dedicated employees who develop the new business models that can arise from all of our possibilities. Returning to the subject of the PE bag: In many cement plants plastic is used as an alternative fuel. We can easily imagine system chains in which the families who have lived from truck driving and manual work in the packing department will be trained sufficiently not only to load and deliver the PE bags, but also to take them back, recycle them or process them into alternative fuel. The customer can then concentrate on his core business and we will deliver and operate the plants and such systems. This will inevitably create a network between man, machine and service around our plants!

PAGENKEMPER: Up until 1989, Haver & Boecker had a classical set-up and was aligned to technologies: We developed machines and opened up new markets. As from 1992, we supplied the two product lines of valve bag and open mouth, which was already a step towards the market. In 2001, we reorganized the company according to business sectors and have since had a customer-oriented structure. The technologies are there. Now we ask the question: What more can we do?

FESTGE: With this development, our goal has evolved further: We do not just want to produce the best machine, but to ensure that the process we design can optimally make available such elementary products as food or building materials. This expands our vision. The core competence of our customers is the manufacturing of cement. Our core competence is, however, the packaging. If a customer is willing to relinquish this responsibility, then we are ready to take it on. There is an amazing amount of demand for this.

FESTGE: Of course, we will not overburden ourselves here. We are fully aware of the risk and also have very specific customers in mind. But we think it is important to emphasize that we normally have the optimum solution for every customer, and if not, we develop new customized solutions on the basis of our global cross-industrial experience. The customer can focus on his “core business” and we use our internal synergies and provide the best solution. This also means that we apply ourselves to new topics such as Industry 4.0. Today we send our machines like “half-orphans” into the world and then see them only every now and again. We want to equip our machines so that we can communicate with them – and of course, the customer will also be able to communicate with his machine. There is still a lot to do on this sector.

BEDNARZ: Yes, the basis is certainly process orientation together with our technology subsidiaries. Haver & Boecker is distinguished by the fact that we not only supply the machine technology, but also the entire periphery. When desired, we can also supply the buildings, as both steel and concrete structures, together with the lighting and all the required equipment.

PAGENKEMPER: Absolutely. We do not wish to be a purely mechanical engineering company, but a full service provider. We can supply the entire plant.

FESTGE: … When desired! As we have said, we are familiar with the process chains and have the necessary skills in-house. What is the optimal machine arrangement? How can the bags be transported most efficiently? We possess this know-how.

FESTGE: It will certainly depend on the dimension. We will not take on such a big risk that it might harm us sometime. But we are able to work efficiently, we master the challenges and we are well positioned. Our preference is to have healthy growth in different markets. The development of our company into new fields is the consequence of our actions, but not our primary goal. We gladly accept new challenges, but have respect for them. That has nothing to do with arrogance or bravado! Because we are a medium-sized company ourselves, we know our customers very well. So they can rely on us and, for instance, allot their assets differently.

PAGENKEMPER: In this connection, I would like to mention that we are working on a new business model: The customer buys a packing machine and finances it via the bags.

FESTGE: Yes, that’s right. That can be a good argument for the customer.

PAGENKEMPER: My opinion is that TCO (Total Cost of Ownership) is an obsolete concept, and that we now are moving into an era in which all stages will be interconnected – “Time to Chain”.

PAGENKEMPER: We do not see any focus on particular regions of the world. We are active in the whole range of different markets. If business does not run smoothly in the construction sector, it runs better in the commodities or foodstuffs industry.

BEDNARZ: In regions where infrastructures are currently just developing or expanding, all of our divisions are active: foodstuffs, building materials, chemicals, raw materials…

FESTGE: Our network is well-established and we are present everywhere in the world – with our technology subsidiaries, regional subsidiaries or representatives. We utilize our in-house synergies.

PAGENKEMPER: Take Africa, for example: We are present there with a very diverse range of products in different markets, and since 1960 we have delivered over 960 packing plants to 41 countries!

BEDNARZ: Business in Africa does not develop by leaps and bounds, or with great returns, but progresses constantly and steadily – one just has to have lots of patience.

FESTGE: As is the case elsewhere, Africa’s infrastructures have to grow, and the demand for cement is steadily increasing. The huge cities that are developing have an immense demand for building materials. And, one must also be present and able to satisfy customers so that a good relationship can develop. But we are broadly positioned in terms of technologies, industries and regions. This makes us resistant to crises.

PAGENKEMPER: In addition, we also see another interesting connection, which emphasizes the importance of the packing plant: If one looks closely at the cement production process, one quickly discerns that the upstream process steps are actually far too expensive for the produced cement to be packed with an inefficient machine. The customers are increasingly realizing this.

FESTGE: In this respect, it helps if we can offer single-source technology, knowledge of the industry, and process and project management. The cement plant of the future will only be a highly efficient process if all the involved technologies are intelligently linked!

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.