The next generation of cement packing

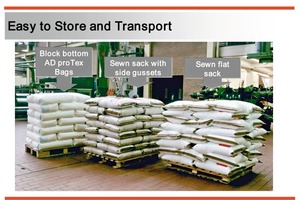

With increasing global cement production and new players in the market, a better packaging solution is required. Block bottom heat-sealed woven PP bags offer a number of advantages over conventional sewn woven PP bags.

1 Jute bags for cement

Uncoated HDPE bags were first used to pack cement but they could not sustain the temperatures of the cement during packing. Such bags made from PP tapes however offered a very good solution to the cement packaging needs in India. The PP tapes are manufactured on tapelines and then woven into tubular fabric. The tubular fabric produced on circular looms is then separated into individual cutoffs by means of a heated knife or wire, printed and stitched manually to produce the present day woven bags which are seen all around the country.

The PP woven bags offered various advantages like favourable economics, good availability, lower seepage, good moisture barrier, good branding due to a possibility of good graphics and print results, lower packaging weight and lower transportation costs etc.

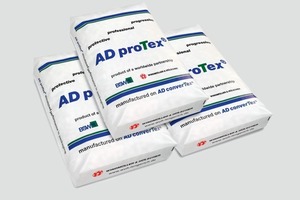

Increasing competition in the cement market, attractive export possibilities and increasing demand for automatic filling and palletizing systems support a better and technical superior packaging solution for cement in India. The german machine manufacturer Windmöller & Hölscher has introduced the brand name AD proTex for bags produced by this technology. They offer various advantages like better aesthetics, less cement dust development, low loss, low breakage rate, easier transportation etc. which in addition to the above also helps making the cement packer to end user cycle cost effective (Fig. 1).

2 Manufacturing of AD proTex bags

3 Equipment and various processes

to provide a homogeneous melt at uniform temperatures. The melt temperature must be sufficiently high to melt the resin completely without excessively degrading the polymers (degradation describes the break-up of the polymer chains by excessive heat).

to shape the extrudate to the desired form and dimension ( in our case to a film which is eventually slit to produce tapes)

to incorporate other materials like additives, pigments etc.

Before stretching, the polymer chains in the tapes are arranged randomly, in no specific order. The subsequent stretching process with a draw ratio of about 1:5.5 elongates the tapes, making them thinner and narrower, and, more importantly, orientates the polymer chains in the longitudinal direction. This orientation is the reason for the high tenacity of the tapes. In order to facilitate the orientation the tapes are heated to softening temperature (precisely: crystalline melting temperature) while passing a hot air oven.

Shortly after leaving the oven, the stretched tapes are reheated by means of heated rollers. This annealing process relieves the internal stress developed during orientation and serves to avoid shrinkage of the tapes resp. the fabric when exposed to elevated temperatures at a later date, for instance during extrusion lamination. After cooling down the tapes by means of chill rollers, the tapes are eventually wound on aluminum winding cores on the tape winders.

The coating process starts with feeding the line with tubular (also flat) fabric rolls produced on the looms.

The melt from the extruder is laid on the PP fabric using a flat die. Using a turner bar system on the machine allows a single flat die to coat the fabric on both sides. The coated fabric is cooled by a chill roll. Using either polished oder tarnished rollers results in shiny or matte finished fabrics.

The bottomer uses only air at high temperatures and pressure to create the joints on the bag. The air is directed by nozzles on to the valve-and bottom patches and on to the fabric of the sack body, softening the coating on the surfaces. Immediately afterwards, pressing the sack fabric and patches together creates the joints.

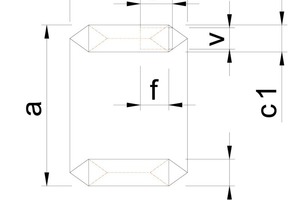

It is of course very important that the AD proTex bags are produced with correct geometry and accurate dimensions. To a large degree, this depends on the quality of the input fabric. The specification of fabric required for the AD proTex bags is shown in Table 3.

4 Advantages of AD proTex bags

The bag is produced by a hot air sealing process and thus requires no stitching or glue for production. Being adhesive free this method is environmentally friendly and makes production simpler and cost effective.

The AD proTex bags are produced with minimum length and width variations, permitting a consistently high filling degree. Lower size tolerances also make the bags more suitable for automatic filling systems and help in easier palletizing.

The bag is designed in such a way that it increases the productivity of the packing machine and minimizes cement dust development during filling. The AD proTex bags feature micro-perforated holes which deaerate the bag during filling while at the same time preventing cement escaping from the bag. The size and the pattern of micro-perforation holes can be easily controlled to optimize the filling rates to control the dust development. Efficient micro-perforation also helps in reducing breakage of filled bags during handling

The heat-sealed joints of the bags feature a supreme strength. Once opened to empty the content however, the bags cannot be closed again thus making it tamper proof.

On filling, the bag takes on a box type shape thus allowing easy stacking (Fig. 5, 6) and offers more printing surfaces than other bag types. The logo of the manufacturer and other information can be read from the sides when the bags are stacked. This increases visibility for the customers and improves promotional effectiveness.

Coated fabric offers a much flatter surface compared to uncoated material resulting in better print quality. Thus the AD proTex bags allow for superior graphics to be printed with very good quality.

AD proTex bags can be seen as a long term strategic solution for the cement industry. The bag is already being used in the Indian market and is well accepted by the end users. Similar trends have been observed in many other countries around the world and some of India´s neighbouring countries have already almost entirely substituted AD proTex bags for other bags.

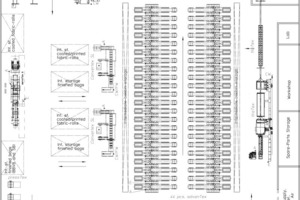

5 Project for the production of AD proTex bags

The required production area is approximately 4500 square meters. Add to this offices, staff rooms, the laboratory and the warehouse, and the total area is approximately 6000 square meters. The design is based on an energy requirement of approximately 1 MW for the entire project, including all supply systems. The compressed air requirement would be 300 m3/h.

Table 4 summarizes the estimated demand for labor to operate a plant with a capacity of 50 million plus bags per year. The number depends on the performance and other variables.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.