Controlling build-ups in dry process cement production

MARTIN ENGINEERINGThe benefits of high-efficiency air cannon networks can include reduced energy costs, improved system performance, reduced maintenance, improved safety and greater total output.

Build-up vs. throughput

Build-up can occur in many places, and in several forms. It can be found as dry material that clings to the walls of pre-heater towers, or as ash that adheres to boiler tubes, SCR units and vessels. Accumulation often appears in riser ducts, feed pipes, cyclones, transfer chutes and storage bins, as well as kilns and coolers. The accumulation can be particularly severe when fuels with high sulphur or chloride content are used, such as pet coke. In extreme cases, massive build-ups can suddenly break loose and suffocate the process, potentially causing significant damage to equipment.

Lost production is probably the most conspicuous cost of these flow problems, but the expense can become apparent in a variety of other ways. Shutdowns to clear the restricted flow cost valuable process time and maintenance hours, while wasting energy during re-start.

Refractory walls can also be worn or damaged by tools or cleaning techniques. When access is difficult, removing material blockages can also introduce safety risks for personnel. Scaffolds or ladders may be needed to reach access points, and staff can risk exposure to hot debris, dust or gases when chunks of material are released.

Air cannons: A proven solution

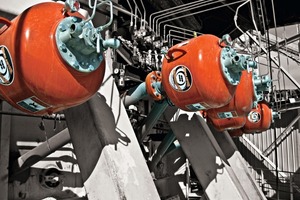

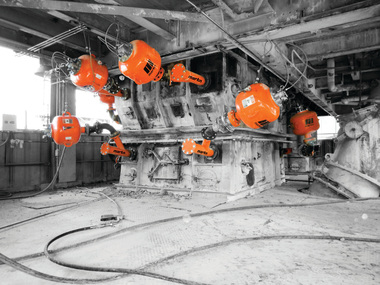

In the cement industry, air cannons are frequently used to eliminate build-ups in preheater towers, often at points such as the riser ducts, feed pipes, kiln inlets and cyclones. They can also be found in extensive use in clinker coolers, in material transfer chutes and in storage bunkers.

Air cannon technology has a long history of service in cement processing, helping to improve material flow and reduce build-up. The timed discharge of a directed air blast can prevent accumulation or blockages that impact process efficiency and raise maintenance expenses, helping manufacturers minimize the need for process interruptions and manual labor.

Basic operation

In many applications, an engineered firing sequence will relieve the build-up problems. The air blasts help break down material accumulations and clear blocked pathways, allowing solids and/or gases to resume normal flow. In order to customize the air cannon installation to the service environment, specific air blast characteristics can be achieved by manipulating the operating pressure, tank volume, valve design and nozzle shape.

A “typical” air cannon application might consist of 700 liters (25 cubic feet) of free air compressed to 7 bar (100 psi) inside a tank with a 100-liter (3.5 cubic feet) capacity. The valve is designed to be held closed by the pressure of the air supply until a signal triggers a solenoid, releasing the captive air. Today’s fast-acting valves can release the tank volume in less than 300 milliseconds, creating a high-magnitude force at the exit nozzle, which is installed through the wall of the vessel or duct.

In most installations, an air cannon network will be connected to the plant air system, sharing the compressed air with other equipment and processes. If the plant has no air system in place, the cannons may be supplied by a dedicated compressor. Because blast forces are a direct function of supply pressure, effective performance requires adequate pressure and volume of compressed air.

Types of air cannons

Single tank cannons are currently the most used design in cement plants, and can be strategically combined to work as a unified system with a coordinated firing sequence to prevent blockages. They are typically offered in a range of tank sizes (35 l, 70 l and 150 l are common), and provide the option of positive or negative firing valves. They can also be equipped with either positive firing valves (internal design with maximum discharge strength) or negative firing valves (external design that opens in response to a positive surge of air from a solenoid).

A multi-valve air cannon system that uses a single reservoir and control unit, discharging through stainless steel hoses and/or rigid pipes. These systems separate the air cannon valves from the discharge points, protecting components and personnel from the effects of heat, contaminants, high pressure washing or cardox. The Martin Engineering design can be equipped with either positive- or negative-pressure firing valves.

A multi-port air cannon system (Fig. 4) operates on a slightly different principal, delivering its air blast to as many as eight ports using an air cylinder, without conventional valves. These cylinders have been designed for durability and are able to operate for millions of cycles without maintenance. Martin Engineering’s multi-port technology provides air refill times in the range of just 20-50 seconds.

Air cannon maintenance and efficiency

Material avalanches can also force debris back through the valves of conventional air cannons, severely hampering their effectiveness or even rendering them completely inoperative. Poor air cannon performance can also be directly linked to high-pressure water washing, which can cause piston failure and nozzle clogging. There are a variety technologies available to help enhance air cannon performance and system life across the harshest working conditions.

Guarding

Valve design

Even in just the last few years, new valve technology has produced significant performance advancements in air cannon designs. The new family of positive-action valves from Martin Engineering produces about twice the blast force output of the valve generation introduced a decade ago, while using about half the compressed air volume.

If the two designs were set to deliver the same discharge force, the new design would operate at about half the pressure, further reducing the compressed air consumption to about ¼ of that used by the old valve design. Specifying an air cannon network with the more advanced valve will cost slightly more up front, but the savings will more than pay back the difference over the life of the system.

Reservoir technology

When equipped with a return reservoir, the air cannon produces an initial blast force of the same strength, but the duration of the discharge is reduced. Instead, some air is retained inside the cannon’s tank, minimizing the overall air consumption without reducing the initial output force. Since the main air tank is never completely evacuated, the volume of air required to refill after each discharge is reduced.

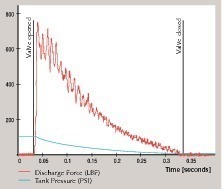

Figure 5 illustrates the force and pressure curves of a typical air cannon discharge. The blast force output reaches its peak in the milliseconds just after the valve is opened, dropping quickly as the tank pressure approaches zero.

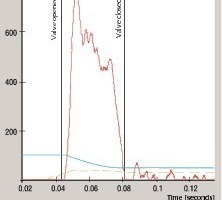

For comparison, Figure 6 shows the force and pressure curves of an air cannon discharge from a unit with a return reservoir. The peak force output remains the same, but air consumption is reduced by about half, easing the demand on the facility’s air supply and saving the plant money.

The return on investment from compressed air savings after installing a return reservoir on a typical high-efficiency valve system is often around 18 months, depending on specific process details. Plants operating older generation air cannon networks can take advantage of new retrofit valve designs to upgrade performance even further.

Conclusion

Improving air cannon efficiency and reducing air consumption also helps lower operating expenses. For new installations, an air cannon system with high-efficiency valves will deliver effective material movement, while reducing compressed air requirements. Upgrading the valve and/or installing a return reservoir can further reduce the air demand of existing systems, even those with old-style cannons.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.