Synthesis gas from residues containing PVC

The Ecoloop process for manufacturing high-grade synthesis gas (syngas) from wastes containing PVC is currently in the commissioning phase at the Rübeland plant near Elbingerode. ZKG INTERNATIONAL visited the plant to update our information.

Such gasification...

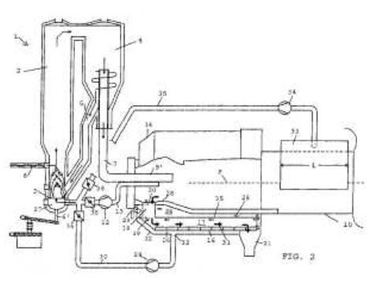

Such gasification processes are actually nothing new. However, project developer and manager Roland Möller says that the Kaltes Tal system is special: “It accepts very large-sized feed material” he says. It therefore requires no complex and expensive material preparation such as that needed for the pellets used by the steel industry or the alternative fuels used by cement factories. Furthermore, the waste materials burnt in cement kilns require presorting in order to obtain the needed physical properties and calorific values. “After a simple size-reduction stage, we have usable streams of material that can also contain harmful substances such as chlorine, which in other systems often cause problems with the burning process”, explained the project developer. The Ecoloop process therefore offers the waste industry a chlorine reduction method combined with simultaneous concentration and bonding into the lime. In the case of waste materials containing heavy metals, the same effect is achieved – the produced syngas has a low content of these harmful substances, which are absorbed and bonded into the lime during the gasification process.

“We operate the process as a circuit whose source materials are lime and plastics. At the end of the circuit a fine material containing the bonded harmful substances is screened out. The larger-sized lime is again mixed with plastics and returned to the process”, Möller continued. The fine material is relatively easy to dispose of, as the harmful substances are securely bonded into the lime and cannot liberate themselves. However, the aim is to utilize this material in a further process. “The product from the gasification process is a syngas that our firm can use as fuel for our lime burning plants”, says the project manager.

Moving-bed reactor as starting point

The weight ratio of lime to plastic is around two to one, so that there is a surplus of lime. Like the waste materials, the lime is of very heterogeneous composition. The moving bed contains all particle sizes from fist-sized lumps to fine meal dust whose large specific surface is decisive for the bonding of the harmful substances.

The lime serves as a catalytic converter

The gasification process ends in a cooling zone that cools down the ash produced and the remaining lime. This concept was taken over from lime burning technology explained the planner, who is also known by colleagues as “Mr. Ecoloop”. The cooling zone is located at the bottom of the reactor where the gasifying air is fed into the system. “The counterflowing air therefore cools down the moving bed of bulk material, including everything that is not gasifiable, before it reaches the outlet. During this process, the gas itself is heated up to reaction temperature and is thus supplied to the gasification process in a very energy-efficient way – like in a preheater”, said Möller.

The cooled material then passes through a screening section in which the coarse constituents are separated from the fines. The harmful substances are predominantly bonded in the finest particle sizes, which are removed for disposal or dumping, while the larger material is returned to the moving bed of bulk material for another pass through the reactor. “In this way the lime is continuously reduced in size and chemically utilized. The progressive particle size reduction automatically generates the large specific surface required for bonding the harmful substances” said Möller. The amount of fine material in the silo increases in the course of time while the coarse material disappears and has to be replaced by fresh material from the lime plant to ensure that the feed dosing is always constant. The silo is thus the starting point and end point of the cycle.

Material recovery

According to Möller, another possible application might be to process electronic scrap. Although this would result in the production of less syngas than is the case with plastics, the precious metals contained in the components would be of interest. “Recovery of the rare earths contained in numerous electronic components nowadays would make the Ecoloop process really interesting” says the project developer. Using a concentration process, the fine material produced by the gasification could be metallurgically processed to separate and recover these elements. “Our calculations and consultations with university research establishments indicate that the content of rare earths in the fine material produced by the Ecoloop process could be far higher than in the originally mined ores. But the Rübeland plant is too large for that purpose; it would have to take place in a modified, smaller scale facility”.

However, Möller pointed out that no practical experience is so far available for the concentration of such valuable substances, only theoretical considerations. “What happens to such metals as they pass through the reactor? Do they melt? Do they adhere to the lime as molten drops? Or do they oxidize? Do they remain in elementary form? Those are complex points that we have considered but which have not been tested in a pilot plant or experimental facility”. For Möller and his team the clear priority is to first put the Ecoloop system into full industrial operation. In so doing, they are focusing on supplying synthesis gas as a standard fuel for high-temperature processes in an energy-efficient manner. “These other processes are currently just visions that we have theoretically developed in order to patent them. They would involve a further development stage”.

No conflict with waste incineration

The pure thermal efficiency of the plant – taking the net calorific value of the substitute fuel or plastics into consideration and balancing it against the calorific value of the syngas – is somewhat above 80 %. This is a high figure, but Möller says it is normal for counterflow gasifiers. “In the past, the problem was always starting up a counterflow gasifier using plastic waste materials. We solved this problem by using a moving bed of lime”.

Sulphur-free substitute fuel

To counteract the problem, the lime industry had taken the step of using low-sulphur natural gas to produce the required lime. “Quite apart from the economic benefits of the syngas”, Möller sees a great advantage in the Ecoloop product, as it contains no sulphur. During the process, this – like the chlorine – is bonded into the lime and is therefore practically absent in the gas produced.

Also interesting for other sectors of industry

Apart from the cement industry, the Ecoloop team also regards other sectors as particularly interesting for the process. Examples are the lime industry – “As we see here in our plant” – and naturally the hot metal and steel production sectors, which Möller sees as ideal partners. The process is perfect for industrial sectors that operate their own synthetic gas networks. “Blast furnace gas or coke furnace gas are no different from syngas. Such networks sometimes have gas shortfall conditions, so that the Ecoloop system would be an ideal supplementary component. Or paper mills, which sometimes have substitute fuel power stations to cover their high power requirement and simultaneously burn the wastes occurring, for instance, during the waste-paper preparation process.”

Interested companies would naturally also have to consider the cost of constructing a waste utilization plant. But Möller pointed out that the investment cost for an Ecoloop plant is significantly lower than that needed for a conventional grate-firing plant. “Nowadays, the new construction of a substitute fuel power station costs around 1.5 to 2 million € per produced megawatt hour of thermal power. For the same amount of power you would pay less than 1 million € for the Ecoloop process”. Taken together, the comparative simplicity of the process, its easy implementation and the favourable investment volume are very significant arguments for potential customers.

Syngas also usable for power generation

In his mind’s eye Möller sees a further step in the development of the process: “We want to advance the synthetic gas manufacturing process in accordance with the directives of the Federal Environmental Agency to the point where our product can be licensed as a standard fuel – just like gases from the public gas supply system”. This will certainly be technically feasible, but will first have to be verified by a measurement program under the supervision of the FEA within the framework of a plant optimization project. “The first necessity is to put this system here at our Kalten Tal plant into continuous operation”, said the project developer and manager. Following the first test run in spring, the system will start gasifying plastic wastes in summer. “Then we will progressively run the plant up to full-load operation” concluded Möller.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.