Thermal monitoring at E-Sheng Cement in China

The E-Sheng cement plant (Fig. 1) is situated 130 km South East of Chengdu, capital city of Sichuan Province. It is in an environmentally protected area and as such, it is subject to stringent regulations as far as pollution is concerned. The quarry is situated 5 km away on a hillside, 500 m above plant level. Transport of limestone is by one single conveyor.

The plant has 5 identical kilns, each 5500 tpd, i.e. 27 500 tpd total output, making it the largest single plant in the southwest of China. The plant was designed by the Nanjing Cement Institute (NCDRI). Its specific heat consumption is...

The E-Sheng cement plant (Fig. 1) is situated 130 km South East of Chengdu, capital city of Sichuan Province. It is in an environmentally protected area and as such, it is subject to stringent regulations as far as pollution is concerned. The quarry is situated 5 km away on a hillside, 500 m above plant level. Transport of limestone is by one single conveyor.

The plant has 5 identical kilns, each 5500 tpd, i.e. 27 500 tpd total output, making it the largest single plant in the southwest of China. The plant was designed by the Nanjing Cement Institute (NCDRI). Its specific heat consumption is 730 kcal/kg of clinker, 65 % at the precalciner and 35 % at the kiln. Each kiln is 4.8 m dia x 74 m long. Start-up fuel is oil, main fuel is coal, 5500 kcal/kg LHV. The coal mine is 25 km away; coal delivery to the plant is by road.

The plant is checked regularly for emissions, management of the plant is particularly advanced and the staff is well trained, thus achieving a high quality product. The total number of employees is 3000. 15 % of the production is sold in bags, the rest in bulk. Delivery to clients is by road or rail.

The first line was commissioned in 2008, the last in 2010. Due to the 2008 earthquake 300 km away, local demand for cement remains high.

Rotary kiln shell temperature monitoring.

Each kiln is equipped with a high resolution scanner which warns the operator of any refractory lining/coating problems and possible malfunction of the kiln.

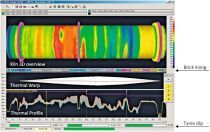

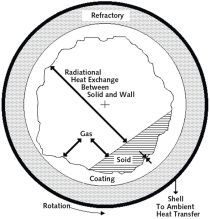

The basic principle of the scanner system (Fig. 2) for rotary kilns was developed some thirty years ago and improved over time, on par with technological advancement and user request. Nowadays, the scanner systems for continuous surveillance of kiln shell temperature has proved to be an essential part of process monitoring in cement plants, helping the operators to better control the burning process on the one hand, and to avoid hot spots on the shell on the other. Indeed, hot spots can cause complete stoppage of the kiln for several days - if not weeks when the shell is badly distorted. The various systems on the market vary a lot as far performance is concerned and differences should be weighed carefully in order to get the full benefit from the system. A high performance instrument with enhanced spatial and thermal resolution is a must. The sampled spot size on kiln must be small enough to detect the fall of a single brick and the infrared detector’s signal noise must be as little as possible in order to detect positively small changes in temperature.

When the above basic requirement is met and only then, an elaborate software will give valuable information such as early stage hot spot detection, real time brick lining wear and coating thickness and kiln tyre slip monitoring. In addition, display of the thermal non-axisymmetrical distortion of the kiln (thermal warp) provides information on the process changes inside the kiln such as evolution of coatings, kiln push of unburnt material, flame adjustment, etc.. With such knowledge, the operator can take the required action at an early stage, thus reacting very quickly on the shell temperature, its distortion and the clearance with the tyres. As an example, after an uneven temperature distribution is detected thanks to the Thermal Warp display, the operator may modify the flame adjustment and the kiln rotation speed in order to adapt the burning conditions and to homogenize wthe coating, resulting in decrease of the axis distortion.

Thermal warp (Fig. 3) helps to evaluate risks such as:

hot spots under tyres

excessive shell out-of roundness under the tyres

tyre constriction on the shell

breakage of tyres according to the fatigue criteria

rollers slackening on their shaft

roller scaling off

bearing bush seizing

The scanner system computer has the possibility to communicate with the plant DCS via OPC, so that the plant can retrieve essential information from the scanner system such as:

Kiln speed

Individual tyre slip status

Individual alarm status

Atmospheric transmission coefficient value

Reference blackbody temperature

Kiln shell heat loss

OPC communication status

The plant

Positioning of each scanner was straightforward, i.e. 25 m away from the kiln (with 112 °C field of view scanner head).

The signal from each scanner is taken into a signal processing unit via fibre optic cables. The processing unit is installed inside the electronic bay room adjacent to the control room. It is connected via an Ethernet cable to the computer and then to the display monitor (Fig. 4).

Preparation work before commissioning consisted of the construction of the scanner tower and support, the brackets for kiln contact switches and the cable installation.

Upon our arrival at site, our Chinese engineer checked the installation work. In order to view the whole kiln axis, fine positioning (using an oscilloscope) of the scanner head is required. The task is usually easy – but when this is to take place at the top of a 15 m swinging pole with 3 workers on it (HGH man + 2 fitter/welders), it can be a little awkward – especially as access is through the middle of the supporting pole itself!

Once the hardware installation is completed, then comes the software configuration. It is a dedicated software for linearization of images, the kiln lining brick characteristics, with access parameters according to the seniority of users. When this set-up is completed and everything is in order, then comes the training which usually takes one complete day.

Conclusion

Each scanner system has been operating without failure of any sort since first put into service. It is usually the way in China – even though the installation may lack protection from the adverse weather conditions.

Today, the scanner systems continue to run smoothly, all functions operating normally.

The plant staff are delighted with the systems which are easy to use (Chinese menu) with clear and precise images.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.