State-of-the-art explosion protection for dedusting of coal grinding plants

Summary: With dedusting of coal grinding plants, the state of the technology is determined by the explosion protection measures, the filtration performance and the design of the plant. To ensure safe operation of a plant, only certified and tested concepts and components should be used for its design and manufacture. With plants protected against explosion, such issues will always affect the plant’s resistance, its explosion relief venting and its explosion decoupling systems. Economic factors, where the aim is minimising the filter level and lean design, should not be forgotten with dedusting and it is important that plants are aligned to the latest state of technological development. With their years of experience and continuing development in the area of dedusting for coal grinding plants, Intensiv-Filter and Thorwesten Vent have succeeded in implementing the state of the art.

Coal is still considered the most important fuel for the manufacture of cement, lime and gypsum. In the German cement industry, despite the increasing use of secondary fuels, the proportion of the total thermal energy requirement is still around 40 % (36.6 million GJ/a) [1]. This value has stabilised over the past few years and the trend is anticipated to be rising rather than falling. Worldwide, coal as a fuel for the cement industry is even more important since secondary fuels are used less and coal is often available locally, making it a low-cost energy source. Particularly...

Coal is still considered the most important fuel for the manufacture of cement, lime and gypsum. In the German cement industry, despite the increasing use of secondary fuels, the proportion of the total thermal energy requirement is still around 40 % (36.6 million GJ/a) [1]. This value has stabilised over the past few years and the trend is anticipated to be rising rather than falling. Worldwide, coal as a fuel for the cement industry is even more important since secondary fuels are used less and coal is often available locally, making it a low-cost energy source. Particularly in countries like India, China and in South-East Asia, a considerable increase is expected in sales of cement and hence in coal combustion over the next few years, due to the construction boom.

As the capacities of furnace systems have become increasingly larger, so the sizes of coal mills have also increased considerably over the past few years. Dedusting plants need to be capable of dedusting volume flows well above 250 000 m³/h, with stricter environmental constraints in some cases. Current dust emission values in Europe are around 20 mg/m³ n.c., a trend which can also be observed worldwide. Intensiv-Filter bag filters are capable of clean gas values significantly below 10 mg/m³ n.c., with no need for any additional measures.

For efficient combustion of coal, it is important that this is suitably finely ground and dried. Generally speaking, vertical mills are used for grinding purposes. For drying, the exhaust gas volume flow of a burner conducted to the mill is used. This is heated directly and, after grinding, used to conduct the coal out of the mill and via a dedusting plant. In the dedusting plant, the coal is separated from the carrier gas and metered into the fine coal silo of the combustion plant. Jet-pulse bag filters currently represent the latest state of development with dedusting plants for coal grinding plants. These have a high level of separation efficiency leading to reduced product losses with low operating costs at the same time. For reasons of safety and environment, electrostatic precipitators are now no longer used.

Coal, as a combustible, finely-ground dust, and when dispersed into air or exhaust gas with a sufficient proportion of oxygen, it forms an explosive mixture. Even if the coal is generally ground under inert conditions, permissible oxygen concentrations may still be exceeded under start-up or shut-down conditions or in case of malfunctions. In the cement industry – unlike in the steel industry for instance – sufficient inert gases to enable additional inertisation of the plant are not available from the process or they can only be realised using very cost-intensive measures. Safety of the plant therefore needs to be achieved by incorporating explosion protection measures into its design. With this, all plant components (mill, pipeline, filter) are designed to be pressure shock resistant to reduce explosion pressure, as well as being equipped with decoupling systems and relief devices.

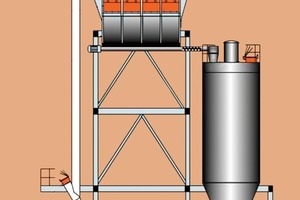

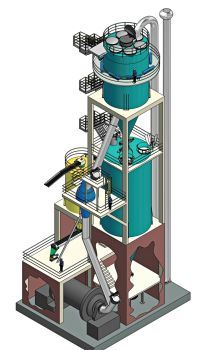

This article describes the latest state of technological development for the design of dedusting in coal grinding plants (Fig. 1), as well as the relevant safety requirements. In addition, it looks at the operating efficiency of dedusting plants and the conversion of old plants.

Whereas mills for coal grinding have a pressure shock resistance of 3 to 8 bar, due to their large size bag filters are designed to reduce explosion pressure to 0.4 bar. Resistance is verified in accordance with VDI 2263, Sheet 3 [2] and DIN EN 14460 [3], which conform in their key requirements. Thereafter, resistance can be calculated using the proposed standards (AD 2000, DIN EN 13445) and confirmed with a pressure test or, alternatively, verified by an explosion test on a prototype. Due to a bag filter‘s rectangular geometry, this calculation is impossible. The same is true for a pressure test due to the size of the filter and the complexity of the test. The only viable alternative is therefore an explosion test on a prototype. Though this is complex, results are transferable to various sizes for bag filter systems with a modular design. As a result of the test, which is conducted with a factor of 1.1 of the required pressure shock resistance, permanent deformations may occur to the prototype but it must not burst. The explosion test must be conducted using the potentially explosive atmosphere for which the device is intended or in a test atmosphere with similar safety features (maximum explosion pressure, maximum increase of explosion pressure).

Two of Intensiv-Filter’s filter series (screwed and welded variants) successfully underwent an explosion test using a certified testing authority (BVS, Exam BBG Prüf- und Zertifizier GmbH, both now Dekra Exam GmbH), in which no deformation of the prototype was visible. Figure 2 shows the test for the Intensiv-Filter CombiJet during explosion relief.

The required relief area for venting the pressure from the filter is calculated according to VDI 3673 [4] and DIN EN 14491 [5]. The size of the relief area is determined by the pressure shock resistance and volume of the filter to be relieved, dust-specific characteristic data of the maximum explosion pressure (pmax) and the pressure rise (KSt value) as well as the response pressure of the relief device. When the filter is erected inside a building, pressure wave and explosion flames need to be conducted out of the building using pressure shock resistant deflectors.

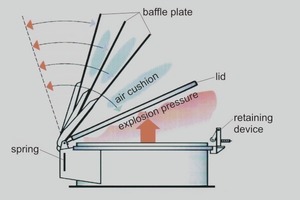

Self-closing, reusable explosion flaps are used with bag filters for coal grinding installations due to their benefits. With the air cushion explosion flap developed by Thorwesten Vent, the sealing flap opens at a response pressure of 0.05 bar and swings against the moving impact plate. As an air cushion is built up between the sealing flap and the impact plate, the kinetic energy of the sealing flap is reduced and it is closed again in its initial position without any damage (Fig. 3). As the relief area is closed immediately, any incursion of oxygen into the process is prevented. Resultant fires or secondary explosions are avoided and backup inertisation can be used. This renders replacement of the relief device, as is required with rupture discs, unnecessary and plant availability is maintained.

When installing the relief devices, care must be taken to ensure explosion pressure waves and flame fronts can be discharged unobstructed both inside and outside of the filter. To prevent closure of the relief area by filter bags, a sufficient distance must be maintained between bags and the relief area and a corresponding restraint system provided for the bags. Outside the plant, the area in front of and underneath the relief area must be kept clear. The range of the flames can be up to 50 m and the pressure wave may still be more than 200 mbar at a distance of 10 m.

The relief devices used must meet the requirements of DIN EN 14797 and be certified according to the ATEX Guideline 94/9/EU as safety devices.

Specifications for the manufacture of pressure shock resistant installations are contained in DIN EN 14460. Selected and approved materials must meet mechanical, thermal and chemical requirements with regard to the design and operation of the filter. Welding work may only be carried out by approved and certified welders. This applies to both the assembly and the erection of the plant at the location. Recoil forces occurring during pressure relief must be taken into account when designing the filter supporting structure.

In the event of an explosion, transfer can occur via all existing connections (conveyors, pipelines, openings) between plant components and the explosion can enter the environment. [6] The explosion leads to dust and gas being compressed beforehand and turbulence is intensified. In the downstream system (e.g. filter after the mill), subsequent flame jet ignition causes a considerably more powerful explosion, which cannot be compensated by the explosion protection systems provided for the individual plant parts. For this reason, it is important to combine suitable explosion decoupling measures with explosion protection measures for the individual systems [7].

Decoupling systems are described in DIN EN 15089. The aim of decoupling is to prevent the explosion pressure wave and a flame spreading via the connection ducts and, in combination with the explosion measures for the plant, to limit this to a safe level.

In case of coal mill dedusting plants, decoupling measures need to be provided at the pipeline between the mill and the filter and between the product discharge of the filter and the coal fines silo. Whereas decoupling of the product output can be achieved using a pressure shock resistant and flame-arresting rotary valve, with the pipeline it is important to look at the pipeline direction and dimensions more closely. However, due to the pipeline‘s large diameter, decoupling measures as described in DIN EN 15089 are not suitable. Explosion diverters (Fig. 4) offer an alternative here. The diverter comprises a pipe system with a relief device (e.g. rupture disc or explosion flap). Decoupling is achieved due to a change in flow direction from approx. 150 ° to 180 ° while maintaining the pressure relief by opening the relief device. Though a recurrence of ignition cannot always be reliably prevented but in rare cases where flames are transferred, the flame speed and explosion pressure can be reduced to a minimum. This precludes ignition by flame jet ignition and excessive explosion pressures so that the explosion protection measures provided in the design of the downstream system are sufficient to protect this [6]. Additionally, explosion diverters decouple in both directions of a plant – from mill to filter and from filter to mill.

Special attention needs to be paid to the length of the pipe between the coal mill and filter. Due to the arrangement of the mill close to the ground and the positioning of the filter above the coal fines silos, the pipe length between the coal mill and the filter is generally 50 up to 100 m. In case of an explosion in the mill, the explosion continues into the pipeline to the filter. Due to the enhanced pressure shock resistance of the mill, high levels of compression and turbulence may be characteristic of the dust/gas mixture. As the pipe length increases, the flame front is accelerated and the explosion pressure rises to a multiple of the initial pressure in the mill. A single explosion diverter at the filter inlet would not be capable of absorbing these forces, nor would it fulfill its function i.e. the prevention of flame jet ignition in the filter. For this reason, either the mill itself needs to be relieved, which is difficult to implement for reasons of construction, or additional relief needs to take place via a venting device directly beyond the mill in the pipeline to the filter (Fig. 5). The multi-stage decoupling system Vent# 1+2 has been validated by Thorwesten Vent in countless explosion tests and is certified as a protection system according to Atex 94/9/EU.

When looking at the degree of efficiency of a firing plant as a whole, besides combustion efficiency of firing, indirect energy consumption also needs to be taken into account. Fan power accounts for more than 80 % of energy consumption for the dust removal process with jet-pulse filters. Since the product of the volume flow and pressure loss of the system constitutes the required fan power and the volume flow is determined by the process, the pressure loss of a filter is the key to energy saving.

The greatest proportion of pressure loss in a bag filter is caused by the filter cake and irreversible deposition of particles in the filter medium. Both conditions are dependent on the composition of the cake (thickness, compression, porosity), dust and gas properties (dust and gas density, particle shape, agglomeration characteristics, moisture etc.) and the properties of the filter medium (surface composition, fibre titre, homogeneity, pore size and distribution etc.) [8].

Taking into account these conditions, Intensiv-Filter offers a special filter medium characterised by optimised surface filtration which goes under the name of ProTex. The use of micro-fibres on the filter face with a titre of < 1.5 dtex can both reduce residual pressure loss and the initial gradient of the pressure loss curve. The overall pressure loss of the system is significantly lowered and at the same time the separation efficiency is high.

For use in filters for coal grinding plants, polyester-based

ProTex PES is already available and this can also be equipped with additional hydrolysis protection. Filter media from polyacrylo-nitrile (PAN) respectively PES/PAN blended needlefelt media as often used in coal grinding processes are currently undergoing validation with regards to ProTex properties.

A further increase in energy efficiency can be obtained by shortening the length of cleaning time. This method has been conceived by Intensiv-Filter using the name Three E (Enhanced Energy Efficiency) and is implemented with new filtering installations or when upgrading old plants. In conjunction with ProTex filter media, a pressure loss reduced by a factor of 4 could be verified in the pilot plant across the raw gas and clean gas side of the filter [8]. In practice, a minimum 20 % reduction in energy consumption is anticipated.

The reduction of length of cycle to < 150 s also ensures an increase in the operational reliability of the filter. Due to the continual cleaning of coal dust from bags, the dust concentration in the filter and hence the likelihood of explosion and fire hazard is reduced to a minimum. Due to the microfibres used, the resistance of the bags is increased and their lifetime guaranteed.

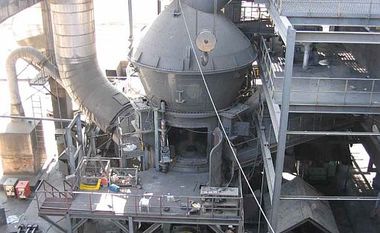

Coal grinding plants which have been in existence for more than 15 years have a complex dedusting plant comprising a separator, cyclone and downstream jet-pulse filter. Energy expended to overcome the pressure losses and operate plant components is considerable and the existing safety concept no longer corresponds to the latest state of technological development.

Extensive conversion work needs to be planned for old systems when increasing the capacity of the plant e. g. for upgrading the mills but also for adjusting the safety concept to today‘s standards. In such cases it is worth taking a look at the plant as whole with regards to energy efficiency and safety. In most cases, cyclones and backup fans can be removed from the system and compensated by an expansion of the existing jet-pulse filter. The safety of the system as a whole is increased considerably as the number of safety systems required is reduced due to the lower number of plant components.

With the concept developed by Intensiv-Filter and Thorwesten Vent, operating and investment costs are significantly lowered, the safety of the system is increased and the specifications of the Atex guidelines are met.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.