KHD: Ongoing steps towards customer orientation

As a customer-oriented company, KHD Humboldt Wedag focuses on spreading more awareness among cement manufacturing companies. HW India has started a series of workshops imparting detailed working knowledge regarding KHD proprietary equipment. The number of KHD roller presses in India is more than 55 and it is therefore vital to familiarize end users with the operation of this core grinding equipment. HW India has already conducted two workshops on the roller press viz. at Shree Cement LTD and Grasim Industries LTD.

The two-day workshop session is aimed at plant operators, maintenance personal,...

As a customer-oriented company, KHD Humboldt Wedag focuses on spreading more awareness among cement manufacturing companies. HW India has started a series of workshops imparting detailed working knowledge regarding KHD proprietary equipment. The number of KHD roller presses in India is more than 55 and it is therefore vital to familiarize end users with the operation of this core grinding equipment. HW India has already conducted two workshops on the roller press viz. at Shree Cement LTD and Grasim Industries LTD.

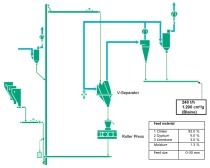

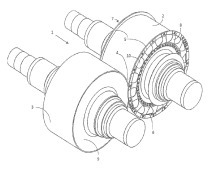

The two-day workshop session is aimed at plant operators, maintenance personal, investors and project teams, both as a follow-up for staff already working with the roller press and staff in preparation. The workshop is designed to enable the attendees to operate and manage the roller press more efficiently with both continued high output rates and reliability (Fig. 1). The two days at site goes into details of most of the aspects of the equipment. Starting with the basics of communition technology, experts give a brief synopsis of the four generations of roller presses. The design and construction session discusses each individual part of the roller press such as its surface, bearings, shaft, lubrication, roller guide, housing, support etc. In order to maintain each and every part of the roller press, various preventive actions have to be taken such as the use of metal and magnet detectors, maintenance at prescribed intervals, accessing and immediate actions for any damage etc. These maintenance practices along with the various forms of CHF, stud or ILP surface repairs are explained on the first day of the session. Another topic will deal with the process behind roller presses. This section covers the working principle and sequence of operation, along with 3D illustrations that are shown from time to time throughout the interactive exercises (Fig. 2).

The second day of the workshop highlights the instrumentation and automation system of the roller press which includes the description and operation of ROLCOX. In addition, this session discusses the instruments associated with the safety of the roller press. The most important section is the detailed explanation of the roller press hydraulic system. Another discussion covers how the roller press in various applications and configurations can be used to achieve the best possible outcome. A site visit and hands-on training is concluded with an explanation of troubleshooting the problems, if any, associated with the roller press.

After receiving positive feedback from the two groups for which these workshops were conducted in India, KHD looks forward to carrying out these types of workshops for all the core cement plant machinery for all its clients worldwide. In the words of the participants “We look forward to similar workshops which provide us with so many details of the equipment in daily use”.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.