Hydraulic binders in the course of time

On November 1, 2009, Univ.-Prof. Dr.-Ing. Horst-Michael Ludwig succeeded Univ.- Prof. Dr.-Ing. habil. Jochen Stark as head of the F. A. Finger-Institute for Building Materials Science of the Bauhaus-University of Weimar. The F. A. Finger-Institute team is responsible, inter alia, for organization of the triennial international ibausil conference (www.ibausil.de).

Born in Weimar, Prof. Ludwig was trained at the University of Architecture and Civil Engineering (abbreviated “HAB” in German) in his native town, gaining his doctorate in 1996 with a thesis on the role of phase transformations in...

On November 1, 2009, Univ.-Prof. Dr.-Ing. Horst-Michael Ludwig succeeded Univ.- Prof. Dr.-Ing. habil. Jochen Stark as head of the F. A. Finger-Institute for Building Materials Science of the Bauhaus-University of Weimar. The F. A. Finger-Institute team is responsible, inter alia, for organization of the triennial international ibausil conference (www.ibausil.de).

Born in Weimar, Prof. Ludwig was trained at the University of Architecture and Civil Engineering (abbreviated “HAB” in German) in his native town, gaining his doctorate in 1996 with a thesis on the role of phase transformations in the performance of concrete under exposure to freezing and to de-icing salt. He then worked in senior management at Schwenk Zement KG, as head of Research & Development for the entire Schwenk group, and as Chief Executive Officer of ZEMBET-Entwicklungsgesellschaft mbH, a research corporation operated jointly with BASF AG, and dedicated to the research and optimization of the interaction of organic substances with cementitious building materials. From 2008 onward, Prof. Ludwig was responsible, as head of R&D/Innovation, for support and coordination of the HeidelbergCement group‘s global R&D activities. He received the Readymix Concrete Promotion Award in 1996, and has, in the course of his career, been a member of a range of specialist bodies and committees.

As the director of the institute, and Professor of Civil Engineering Materials, Prof. Dr.-Ing. Ludwig will definitively steer and shape the development of an institute which has in the past researched and publicized numerous fundamental aspects of the hydration of cementitious binders. ZKG INTERNATIONAL took his new appointment as an opportunity to examine Professor Ludwig‘s career in the building materials sector in more detail, and to ask him a number of questions concerning the future of the institute and of hydraulic binders.

Prof. Ludwig: Well, Weimar is, of course, more than just a “location” for me, when you remember my personal links to this city and its people. So my new professorship has a very special meaning for me, far above and beyond my purely professional responsibilities. A well-founded and practice-orientated training in Weimar gave me an excellent basis for my career development, and enabled me to meet later challenges. A particular benefit was the fact that, in Weimar, we were given comprehensive knowledge ranging from the basic raw materials for production of building materials, up to and including the use of these materials in the finished structure – from the quarry through to prestressed concrete, so to speak! My predecessor and mentor, Professor Stark, developed the F. A. Finger-Institute for Building Materials Science to international leadership in many fields of building materials research. No one, least of all myself, is in any doubt that I am following in the footsteps of greatness here in Weimar. I have the privilege of taking over a well developed department which is, by tradition, of great importance. So my intention is, naturally, to continue this successful concept - in other words, there will be no radical changes in terms of content. On the other hand, I do intend to add a few new aspects to the focus of our research.

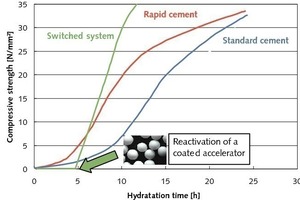

Prof. Ludwig: One important target is most certainly that of actively steering the system “concrete” in such a way that the required properties can be generated in a precisely chronologically defined sequence. Better understanding of cement hydration, and corresponding thermodynamic and kinetic models, are certainly important preconditions for this. Rational modeling will make it possible to discuss the range of instruments necessary for active control. One interesting concept in this context is the “activation” of hydrating systems, with the aim, after an application phase of any length whatsoever, of being able to initiate the hardening phase at a defined time by means of external or internal switches (Fig. 1).

Another means of control is possible via so-called functionalized grinding aids. With “functionalization”, I mean that the grinding aids, above and beyond their traditional functions of increasing throughput, dispersion of bulk material, and so on, are able to systematically modify the properties of the cement. So-called “quality enhancers” are already in use today to increase strength, reduce chromate contents and improve processing and application properties. The possible intercalation of polymers in CSH phases is also a current topical subject – the question: is it possible to incorporate polymers into the layer-structure of the CSH phases and, if so, under what boundary conditions, and with what resultant macroscopic changes in material performance? Integration of the Departments of Building Chemistry and Process Engineering/Recycling into the F.A. Finger-Institute is a mid-term objective, in order to further improve our potential for tackling these new tasks. This new structure will then make it possible to pursue building materials research throughout the value chain, from production (including the burning and grinding processes) up to and including use of the material in structures.

Prof. Ludwig: We are cooperating in a large number of projects in Germany, with the leading building materials institutes in the various fields. Joint research projects are planned into multifunctional materials, for example, and also into the alkali/silica reaction. At international level, we traditionally have good contacts with China and Eastern Europe. Professor Stark managed to set up many cooperation projects in China, and these will, of course, be maintained and, wherever possible, expanded. The issues of reduction of CO2 emissions and alternative binder systems are also becoming ever more important in China. A project for the renovation of historic buildings in Uzbekistan (Fig. 2) is also planned, jointly with the University of Tashkent. I also want to expand contacts with European scientists working in the field of cement chemistry, and with North America as well. There is a whole series of overlaps with North America and Canada in the field of concrete topics, in particular.

Prof. Ludwig: I certainly intend to maintain and broaden our close links with industry, and not only for financial reasons! These contacts are important in so many ways for our department. It is absolutely vital to be permanently focused on reality and practice, to assure the success of the institute’s extremely intensive fundamental research. What should be our objectives, what subjects are relevant? It is also rational for the training of our students to initiate contacts with our industrial partners as early as possible, and maintain them continuously. This enables our students to start their career orientation at an early stage, on the one hand, while, on the other hand, their studies can then be better aligned around the practical needs of potential employers. My predecessor, Professor Stark, was extremely active in this context, and set up contacts with both local industry and with major supra-regional corporations. And there are other industrial sectors which I would very much like to integrate more closely into our activities, such as building chemistry, for example, which is set to play an increasingly important role in the building materials sector in future.

Prof. Ludwig: The cement industry produces around 5 % of global anthropogenic CO2 emissions, so it is directly affected by the current climate debate. CO2-emissions trading introduces an economic factor, alongside the ecological aspect. Auctioning of the CO2 certificates was under discussion recently – and a range of studies demonstrate that this would have had catastrophic consequences, both for the German cement industry and for the environment. Imports would have dominated the market through large areas of northern and central Germany. The result would have been massive relocations of production, not to mention the enormous quantities of additional CO2 emitted due to the extra transportation needed. The entire emissions trading system would have been negated.

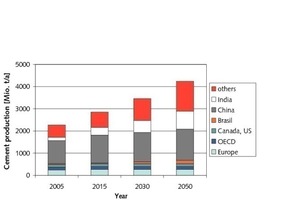

Against this background, the EU ultimately made the right decision in continuing to assign the CO2 certificates, in the framework of benchmarks, free-of-charge to the cement industry, and to other industries on the so-called Carbon Leakage List. This, however, is not to say that this will remain the case ad infinitum. The total quantity of CO2 certificates is, in any case, to be cut by 21 % by 2020 and the cement industry must, and certainly will, consider other methods of reducing CO2. The International Energy Agency has, on behalf of the G8 nations, drafted a Technology Roadmap which discusses the provisions necessary for long-term reduction of CO2 emissions in the cement sector. I don‘t agree with everything this study says, but it does make a number of interesting points. It is assumed, for example, that the global cement industry will be capable of reducing its CO2 emissions by 17 % by 2050, despite the fact that forecasts predict a more than 100 % increase in global cement production by that time (Fig. 3). Carbon Capture and Storage (CCS) is seen as an essential method of attaining this aim, and is claimed to be capable of contributing 56 % of the targeted decrease. Demonstration projects on this new technology are already being planned and prepared. But to reach the reduction target it would be necessary from 2025 onward to equip every new kiln with such a system, and that would involve enormous costs. I personally still have considerable doubts whether CCS technology will really achieve such importance.

Three other instruments which are already in intensive use today are also mentioned here. Enhancement of energy efficiency by reducing energy consumption in production of clinker from 4.2 to 3.2 GJ/tclinker is expected to contribute around 10 % to the total reduction in CO2 emissions. And 24 % of the targeted CO2 reduction is to be achieved by increasing the proportion of alternative fuels used, from 3 % at present to a future 37 %, with a high biomass content. Finally, reduction of the clinker cement factor from 79 % to 71 % is expected to make a 10 % contribution. All these analyses assume that there will be no decisive technological advances in cement production in the next few years, however – and that is exactly where I have my doubts, since the pressure for innovation is extremely high, and many research projects are aimed in precisely this direction.

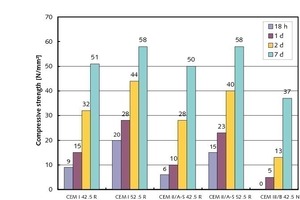

Prof. Ludwig: The study of alternative binder systems is a direct consequence of the CO2 controversy. The subject can, in principle, be subdivided into four focuses, all of which are under examination in Weimar. The first is concerned with the greatest possible reduction of the clinker factor by means of suitable composite materials. The most important challenge here is to maintain the traditional performance of a Portland cement even at high composite contents. The early and earliest strength of those cements can be problematic for their application in a precast plant (Fig. 4). However, a whole series of new conceptual solutions to increase reaction velocity of composite cements already exists. Another factor is the availability of reactive composites – analysis of the available quantities of these materials indicates a maximum realistic substitution rate of 35 %, and we are therefore also searching for alternative composite materials. We intend, for example, to determine whether calcined clays or modified converter slags can also be used.

The second focus is on clinker-free and low-clinker binder systems, which are mainly used at present only for special applications. The question is how binder systems – super-sulfate cements and geopolymers, for instance – can be modified in such a way that they can be used in a broader range of applications.

The third aspect is the re-examination of known low CO2 binder concepts, such as active belite cement, for example, and sulfoaluminate cement. These familiar concepts can nowadays be further elaborated and then used in practice, thanks to the new technological potentials available now.

Finally, a very decisive field of activity is the research and evaluation of entirely new binder systems. Celitement, in particular, has become the center of interest here recently. It’s a cement produced by hydrothermal synthesis of a low-calcium raw mix in a pressure autoclave at around 200 °C, then reaction grinding of the intermediate product with an SiO2 component. This approach appears to me to possess incredible potential, since it permits achievement not only of CO2 reductions and energy savings, but also of an entirely new binder performance. The fact that, in practice, only C-S-H phases, with a low C/S ratio, are produced during the hydration of Celitement means that cementitious building materials will be able to advance into totally new performance dimensions. But scale-up of the process from laboratory to industrial dimensions must first be achieved, and the performance characteristics in use of the binder, including its durability potential, must also be determined, before all this can become possible.

Prof. Ludwig: Firstly, the building material of the future will be extremely ecologically orientated. Even today, subjects like reduction of CO2 emissions and building material sustainability have become a fixed element in corporate philosophy at many building materials companies. My experience in industry tells me that the ecological orientation of these building materials is used not simply as a marketing tool and that, on the contrary, it has an increasing influence on customers’ purchasing decisions. The Environmental Product Declaration, or EPD, will play a special role in future, and will be the basis for ecological balances, and will therefore be demanded increasingly by the consumer.

Health aspects will also become more and more important as time progresses, as is already demonstrated today by current developments in the reduction of chromate contents in cementitious systems, and the introduction of alkali-free shotcrete accelerators.

Alongside the trend toward binders with an improved ecological balance, it is also apparent that cement producers are increasingly tailoring their products to specific applications. The old principle of a homogenous mass product covering all applications, from an adhesive up to and including prestressed-concrete bridges, is therefore shifting more and more toward highly specialized high-performance binders. This trend will result in previously unknown performance classes in terms of processing and use, setting and durability.

Most important, the building material of the future will also be multifunctional and low-maintenance. We already have building materials which can clean the air, or store heat, and also self-cleaning systems. This trend toward multifunctionality, with the building material performing other tasks in addition to its traditional static functions, will continue onward. Building materials will also become “smarter”, thanks to internal or external switching systems, and to “self-healing” and – using sensors – self-diagnosing systems. Further on into the future, systems based on the principles of biomineralization are also conceivable, and will permanently change building materials and building itself. And, with all these innovations, the economic aspect must never be forgotten, of course. Annual consumptions of around eight billion m3 of concrete and two billion tonnes of cement make it clear that the most important building materials are mass products par excellence, and that they cannot be replaced on a one-to-one basis by high-priced alternatives.

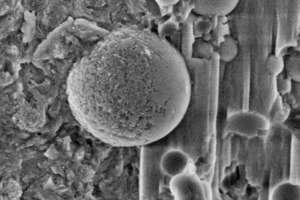

Prof. Ludwig: Dr. Möser has already highlighted the new potentials and technologies in a two-part article in ZKG INTERNATIONAL. The strengths of this method can be found, with certainty, in the combination of ultra-high-resolution imaging and the ability to examine specimens microscopically both under a low-vacuum steam atmosphere and, uncoated, under high vacuum, with an extremely low acceleration voltage. The instrument itself (Fig. 5) thus permits analysis of structures that we have never before been able to see with such clarity.

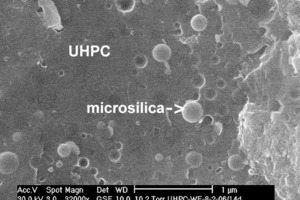

It is ideal for studying surface effects and for imaging of extremely dense structural compositions in ultra-high-performance concrete (Fig. 6–8). In addition to its innovative imaging technology, this instrument also has a cryo-preparation unit, which means that we can now investigate hydration processes time-resolved without disturbing the corresponding solution equilibria. In addition to the generally known EDS system for spatially-resolved determination of chemical composition, we now also have the capability, for the first time, of acquiring crystallographic data and thus, spatially-resolved, information on mineral phase composition, using electron backscatter diffraction (EBSD). With all these analytical potentials, however, I must emphasize that even the very finest equipment cannot give its best without outstandingly proficient technical staff, and I am extremely pleased that with Dr. Möser and his staff, we have a world-acclaimed team in this field.

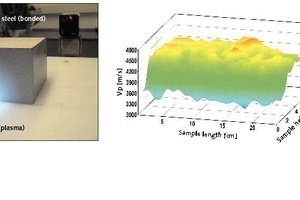

Prof. Ludwig: Four other new instruments are on order for the cement analysis sector: firstly, an ICP mass spectrometer, for trace analysis and analysis of pore solutions, and a spatially resolved XFA is at the procurement stage. XFA data are currently determined only integrally, using fusion, or powder, tablets, for instance. This instrument will close the gap between conventional XFA and the EDS performance of the scanning electron microscope, since it can also determine element distribution at the macroscopic level. In the field of mineralogy, we recently bought a new X-ray diffractometer with an extremely high-speed detector, which will expand our Rietveld activities. Finally, we have also received a new IR instrument, including microscope, with which we intend, mainly, to accelerate polymer research in the scope of Prof. Dimmig-Osburg‘s professorship. Outside the cement-analysis sector, other large-scale instruments are also planned, or have recently been procured, e.g. for the Building Diagnostics and Durability Departments, in particular, including a geo-radar, a laser-ultrasonic instrument (Fig. 9), and new CDF testers for the freeze/thaw test. But one project which will have nothing to do with sophisticated instruments, but which must under all circumstances be tackled, is the renovation of the institute building. We intend to do everything conceivable, in cooperation with the university senate, to restore the building to a condition worthy of a university of civil engineering.

Prof. Ludwig: The recently introduced Bachelor/Masters course for building-materials engineers, which we established here last year – after a great deal of preparatory work – will be the central focus of our teaching activities. I am firmly convinced, given the increasing complexity of building materials systems, that a building materials engineer, with an extra – and profound – understanding of building materials and the underlying building chemistry and mineralogy, as well as the fundamental principles of mechanics and building design, will, in practice, be needed, to support the traditional civil engineer. In introducing this new course, we are, naturally, dependent on the support of industry, which, in the building and building materials sector, in particular, is confronted with great challenges, and needs well-trained young people. In this context, I would greatly welcome clear signals from industry, indicating to young people that building materials science is an engineering discipline with a future and with great prospects.

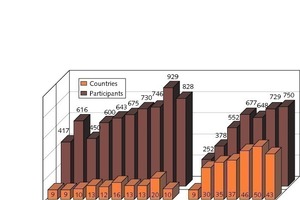

Prof. Ludwig: The ibausil has survived the trials of time for many years and has developed into a fixed congress event. We were pleased, last year, to welcome 750 participants from more than forty countries at our ibausil in Weimar (Fig. 10). So the basic concept is sound, and indeed very successful. I would change it only very cautiously, if at all. We are, at the moment, thinking about two specific things – the ibausil is one of the last major German-language conferences in the field of building-materials sciences. And we want to keep it that way, since this means that people interested in building materials at all levels can interact in Weimar. On the other hand, we are increasingly encountering international interest from scientists with no knowledge of German. My opinion is that we must also meet their needs better in the future. We are also currently discussing the question of whether, given the large number of different subjects, it would not be rational to open each main thematic focus with a plenary address. An internationally acclaimed scientist could then introduce the particular field, and summarize the current scientific status. But, apart from this, the ibausil is an event much enjoyed by all those organizing and participating, and we intend, by and large, to keep it in its existing form.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.