Sitrans LR460 continues success in Höver

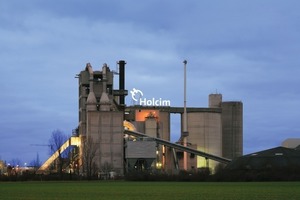

Holcim (Deutschland) AG is the largest producer of construction material in northern Germany, producing more than

4 million t annually of binding material; about 1.7 million m3 of concrete and approximately 3.2 million t of aggregates. Holcim has more than 150 years of experience in the production of construction material. In the Höver cement factory (Fig. 1), Holcim produces 1 million t/a of various kinds of cement. To maintain its high quality and environmental standards, the Höver plant is modernizing its processes.

Cement production re-

quires materials such as aggregates and...

Holcim (Deutschland) AG is the largest producer of construction material in northern Germany, producing more than

4 million t annually of binding material; about 1.7 million m3 of concrete and approximately 3.2 million t of aggregates. Holcim has more than 150 years of experience in the production of construction material. In the Höver cement factory (Fig. 1), Holcim produces 1 million t/a of various kinds of cement. To maintain its high quality and environmental standards, the Höver plant is modernizing its processes.

Cement production re-

quires materials such as aggregates and fuels. Some of these materials are finished and some are semi-finished. Knowing the exact stock of these materials is required for the smooth operation of production. Stock rod mechanical measurement systems have traditionally been used to measure the level of inventory at the Holcim Höver plant. However, stock rod technology provides measurements “on request” rather than continuously and must physically touch the material surface leading to frequent and costly maintenance. In addition, it is not possible to use stock rod measurement technology during the filling cycle due to the possible submergence of the weight on the end of the cable.

In spring of 2007, Höver operators were looking for a reliable, continuous non-contacting measurement system for its dusty 45 m high cement silos. They wanted a system that required minimal maintenance yet provided accurate results.

Operators at Höver were already familiar with radar level measurement from Siemens. In 2002, they tested Sitrans LR400 radar transmitters on a finished cement silo. The Sitrans LR400 provided consistent and precise measurement results that were totally unaffected by the extreme dust load in the silo. Based on the high performance of these transmitters it was decided to install Sitrans LR400s on other finished cement silos, as well as raw material, clinker, and additives silos.

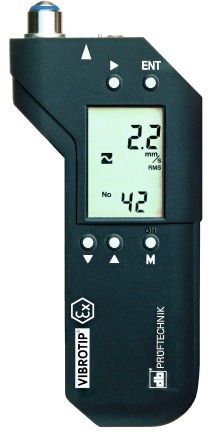

In choosing a radar system for the cement silos, operators once again looked at selecting a Siemens solution. They chose the newest generation of the Siemens solids radar level measurement devices – Sitrans LR460 (Figs. 2 and 3). It provides operators a number of new and useful features that help make commissioning and maintenance even easier. Process Intelligence provides exceptional signal processing, the “Quick Start wizard” guides the operator to enter only 6 parameters and has the transmitter operational in minutes and the extended diagnostic functions provide better monitoring of process conditions.

Both the Sitrans LR400 and the Sitrans LR460 use 24 GHz FMCW (Frequency Modulated Continuous Wave) technology. The 4-wire technology and 24GHz frequency allow optimal penetration of dust. The small antenna system with a maximum size of 100 mm has an adjustable universal flange allowing easy replacement of existing measurement systems. Thanks to the narrow beam angle, both transmitters can be installed on high and narrow silos without difficulty.

Sitrans LR460 can measure very long ranges up to 100 m and installation is easy with the built-in universal Easy-Aimer. It provides optimal aiming of the transmitter to the material surface and a wide selection of optional antenna extensions allowing installation in existing standpipes without modifications. The maximum allowable flange temperature of 200 °C allows operation on high temperature applications such as clinker silos and furnace dust applications.

Process Intelligence features a dynamic TVT (Time Varying Threshold) which automatically adapts signal processing to the constantly changing conditions in the silo. Combined with the extremely high signal-to-noise ratio, measurements are fast, repeatable and reliable.

The Intrinsically Safe handheld programmer enables safe on-site local programming, without opening the housing of the Sitrans LR460. Optionally Simatic PDM offers the possibility for easy remote configuration with HART® or optional Profibus PA communication.

Since commissioning, the Sitrans LR460 has been operating in the Holcim Höver plant, continuously and fault-free. The dusty environment has caused no problems, resulting in reliable operation. The added features of the Sitrans LR460 made installing and programming the units very easy and operators are confident in installing the units themselves.

Sitrans LR460 has no moving parts, and is non-contacting resulting in considerably lower maintenance costs, as operators no longer need to continuously clean the stock rod mechanical systems. “We are very happy with the advantages the LR460 has provided to our facility. We now know the levels in the silos at all times and our operators are able to spend their time elsewhere instead of cleaning our measurement systems” comments Mr. Marc Lehmann, from Höver.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.