SamsonTM receiving units for Tilbury

About two years ago, Cemex in the UK presented their plans

to erect a new cement grinding works in the Port of Tilbury.

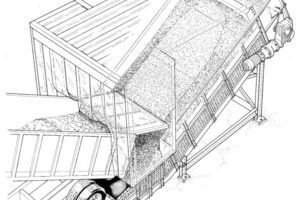

The 1.2 million t/a plant is the only cement plant in the South East of England and will increase Cemex UK’s cement capacity by 20 %. For the transport of different bulk materials, B&W Mechanical Handling Ltd, a company of the AUMUND Group, delivered two SamsonTM receiving units (Fig. 1) to the new cement works in Tilbury. The first machine of the type SamsonTM 800 is ten metres long (holding capacity 47 t, discharge at 95–300 t/h) and used for the clink-

er transport. A...

About two years ago, Cemex in the UK presented their plans

to erect a new cement grinding works in the Port of Tilbury.

The 1.2 million t/a plant is the only cement plant in the South East of England and will increase Cemex UK’s cement capacity by 20 %. For the transport of different bulk materials, B&W Mechanical Handling Ltd, a company of the AUMUND Group, delivered two SamsonTM receiving units (Fig. 1) to the new cement works in Tilbury. The first machine of the type SamsonTM 800 is ten metres long (holding capacity 47 t, discharge at 95–300 t/h) and used for the clink-

er transport. A second SamsonTM 800 along with a 16.0 m long transfer belt conveyor was supplied by B&W to transport limestone, gypsum and plasterboard with a holding capacity of 44 t and discharges at 30–120 t/h. The delivery scope also included silo discharge gates which were delivered by AUMUND

Fördertechnik in Rheinberg/Germany.

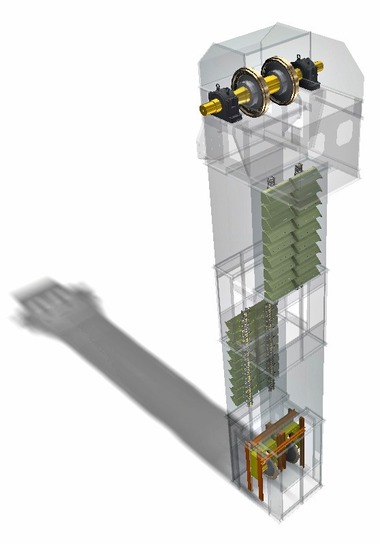

The SamsonTM concept (Fig. 2) which combines a steel plate apron style conveyor with a flat cover belt, unites the benefits of a torsion-proof conveying surface with the clean operation of a belt conveyor. The uniform discharge of the material directly fed into the machine by tipping trucks results in high transfer capacities, while at the same time the low height of fall considerably cuts down the dust generation when material with a high content of fines is fed. The SamsonTM unit is capable of receiving almost any kind of bulk material directly from tipping trucks or loading shovels and enables short-time buffer storage and controlled bulk material transfer onto subsequent components of the works. Thanks to its over-ground installation, the SamsonTM represents the flexible alternative to traditional tipping points with under-floor pits.

The SamsonTM concept was developed by B&W in Ely and after the integration of the British company into the German AUMUND Group is placed on the market worldwide. Consequently, in the meantime the SamsonTM receiving units are found in use all over the world.

With a financial investment that according to Cemex approaches 49 million £, the company set an exclamation mark in Tilbury almost three years after the 100th anniversary of its foundation. The new cement grinding and blending plant at the Port of Tilbury in Essex is to contribute primarily to cover the demand for building materials which is generated by holding the Olympic Games 2012 in London and by the continuing growth of the population in the metropolis.

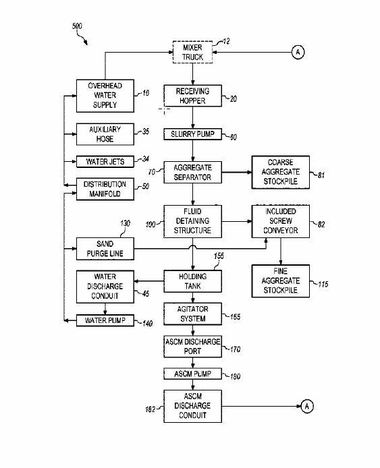

The investment of CEMEX, which is the biggest Mexican investor in the UK, is the largest in the UK cement industry for five years. The new plant has the great advantage of being served by road, rail and river. While clinker currently comes in by road, Tilbury’s deep-water wharf provides the flexibility to import 30 000-tonne shiploads. On-site barge loading facilities also facilitates deliveries made by river to London via a network of wharves. Fly ash comes into Tilbury by rail, this involves a multi-modal transport system, which is a logistical and flexible alternative to traditional silos.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.