Climate protection and energy efficiency –

focal challenges for cement research

6. International VDZ Congress 2009, Düsseldorf/Germany (30.09.-02.10.2009)

The 6. International VDZ Congress, held in late September 2009, was attended by more than 500 specialist participants (Fig. 1). The proceedings were opened by the VDZ chairman, Gerhard Hirth, of Schwenk Zement KG, whose speech of welcome was followed immediately by the opening paper, presented by Björn Stigson (Fig. 2), President of the World Business Council for Sustainable Development (WBCSD), and summarizing the current situation in CO2 emissions trading. Fundamental reports then focused on the complexity of new cements designed specifically to meet market needs, the state-of-the-art in...

The 6. International VDZ Congress, held in late September 2009, was attended by more than 500 specialist participants (Fig. 1). The proceedings were opened by the VDZ chairman, Gerhard Hirth, of Schwenk Zement KG, whose speech of welcome was followed immediately by the opening paper, presented by Björn Stigson (Fig. 2), President of the World Business Council for Sustainable Development (WBCSD), and summarizing the current situation in CO2 emissions trading. Fundamental reports then focused on the complexity of new cements designed specifically to meet market needs, the state-of-the-art in feed materials recovery and grinding technologies, current developments in burning technology, environmental technology and sustainability. The attendees were also able, in parallel sessions, to obtain information on the following topic groups:

The successful commissioning in 2009 of Holcim’s new Ste. Genevieve plant was highlighted in this category. Challenges in the implementation of this major project included the high demand for engineering services and materials during a boom period. The initial operating results from the new kiln line installed at Wössingen/Germany, and impressive examples and requirement profiles for high-capacity plants were also discussed. The fact that the production of white cement makes special demands on the process was illustrated by the example of the Bunol line. Here, modernization has achieved an energy efficiency around 17 % superior to that of the line‘s predecessor. The preheater and precalciner installations are based entirely on a Cemex design; however, new system components were also examined. A new generation of vertical roller mills – the QM2 series, from Polysius – continues the performance trend of its predecessor with a significantly more slender design, and is also available at an attractively low price.

This session illustrated the complex demands made on operators to achieve environmentally acceptable quarrying and mining. The special demands – and potentials – of the use of chalk as a feedstock were examined, citing here Holcim’s Lägerdorf plant. The example of the Saint Pierre La Cour facility was then drawn upon to demonstrate that the use of vertical rather than ball mills for the production of the same cements indeed makes it possible to save energy, but necessitates greater operating know-how. A further factor examined was the service lives of grinding equipment. Up to 60 000 h of operation can be achieved in roller presses using appropriate wear-protection concepts. However, a sophisticated monitoring concept also provides optimization potentials for operation of ball mills. In addition, numerical experiments permit simulation of grinding processes and thus, for example, better understanding of the segregation effects of the ball filling and optimization of these processes.

New cement formulation concepts were studied during this session. Various types, including Celitement and M3K cements, are currently at the development stage and could in future be capable of meeting the doubtless changing requirement profiles. Alternative fuels were also discussed. The increasing percentage of secondary fuels used may necessitate more complex monitoring of (for example) clinker quality, ash content and sulfatization. The fact that cement grades with a lower clinker factor have become established in recent years – as a result, in particular, of the emissions reductions demanded – was also clearly demonstrated. New developments in familiar fields, such as the reduction of chromate content, were also on the agenda here, however. In many instances, joint grinding has in the past proved to be a more effective and cost-efficient approach than addition at a later stage. It was ascertained that, regardless of addition strategy, only continuous monitoring of water-soluble chromium(VI) content can provide legal certainty, however.

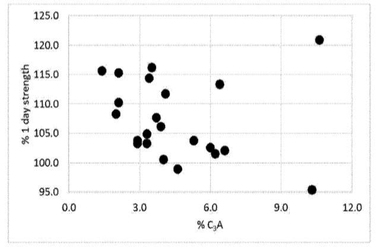

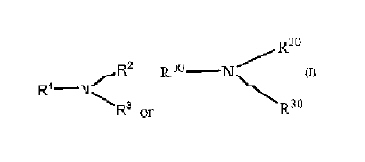

A further focus was on cement chemistry. Hydration behaviour and microstructure development can now be determined, predicted and modeled extremely accurately, and this know-how provides a firm basis for the development of new binders. A challenge which remains to be solved is the depiction of the long-term performance of cement-based building materials. Holistic concepts taking account of both the basic ingredients and the finished materials are needed for this purpose. Finally, it was ascertained that the performance of modern PCE-based binders has been conclusively proved, and that these systems are capable, thanks to their flexibility, of contributing to the development of new cements.

The papers presented made clear that the cement industry already achieves the high efficiency of over 70 %, beating many other industrial sectors in this respect. It was observed that various scenarios for the reduction of greenhouse gases may be necessary, depending on the targets set by the politicians. An information package, the WBCSD Cement Sustainability Initiative “Getting the numbers right” system, which is capable of serving as a basis for cement production around the world, was discussed. The “Asia Pacific partnership on clean development and climate” is also pursuing similar concepts. The economic utilization of waste-heat for energy recovery, impressively illustrated by the example of plants in China, can also be regarded as a step toward the enhancement of energy-efficiency in these facilities. Amortization periods for such projects are around four years in China, whereas in Europe six to seven years is normal in many cases. Here, too, however, rising energy prices and costs for CO2 emissions are accelerating the further development of such systems. An initial approach could, for example, be the recovery of heat from waste gas; up to 100 % of the energy requirement for drying of treatment sludge can, for example, be met from the waste-air leaving the clinker cooler.

A whole series of results obtained by the VDZ Rotary Kiln Burners workgroup on the performance of burners for co-combustion of alternative fuels has now become available. Alternative-fuel burners should, for example, be operated with a higher primary-air component and moment compared to LowNOx burners. The injection of pure oxygen into the flame core can, however, also achieve improved combustion and thus permit higher substitution rates. The parameters of production capacity, investment costs, operation and maintenance, feed material properties, energy efficiency, nitrogen reduction potential and fuel characteristics must also be included in the selection of a kiln system. Modernization of the clinker cooler can also contribute to achieving energy savings, however; satellite and rotary coolers, in particular, have a comparatively low efficiency and necessitate a high level of maintenance. Four examples were cited to illustrate how new coolers can significantly reduce clinker temperatures and energy consumption.

The bypass systems frequently installed recently also permit efficiency increases. One cost-effective alternative is, for example, SOx treatment via recycling of the gas in the kiln and minimization of bypass dust by means of homogenization and pre-separation. Finally, the increasing use of secondary fuels also takes its toll on the refractory lining. Modified materials are then necessary, in order to assure long lining campaigns.

In Cembureau’s opinion the highly satisfactory first revision of the BREF (Best available REFerence document) for cement and lime was unveiled on April 1, 2009. It includes the definition of “BAT” (Best Available Techniques) but not, however, directly applicable emissions limits. Also highlighted, as a pilot project, was a reverse selective catalytic reduction (SCR) system in the semi-dry line at the Sarche plant, which has produced good results for such plant configurations. The filing of patents for this technology for dry processes has also been announced. Further topics on the agenda were the quantification of mercury in the kiln cycle; it has become apparent, inter alia, that the removal of kiln dust to reduce mercury emissions by means of separation with the mill shut down is a more efficient strategy than performing this operation with the mill running. A further aspect focused upon was CO2 removal (CCS, Carbon Capture and Sequestration). In future, pilot plants will be needed to demonstrate whether and how this technology can be financed and applied in the cement industry. The same will also be true, in the mid-term, in the case of industrial scale plants. It has become clear that the use of associated technologies, such as oxyfuel, in the cement industry will require further research, in order to ensure that it remains possible to produce cements of a constant quality.

Professor Henri Van Damme (Fig. 3) received the Klaus Dyckerhoff Prize for outstanding achievements in the field of building-material research at the gala dinner on the second day of the conference, which was chaired by Dr. Martin Schneider, CEO of the VDZ. This honor went to Van Damme, professor at the École Supérieure de Physique et Chimie Industrielles in Paris since 1999, for his lifetime work. The laudatory speakers, including the first prize-winner (2007), Professor Karen Scrivener, emphasized in particular Van Damme’s exceptional achievement in combining a fundamental scientific approach with a practical orientation in research into cementitious materials. The prize has a cash value of 30 000 € and has been awarded biennially since 2007 by the Dyckerhoff Foundation within the “Stifterverband für die Deutsche Wissenschaft” science promotion foundation. This evening event was also the occasion for the award of prizes for advances in Industrial Health & Safety (Fig. 4).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.