Quality – the key to the future

HAVER & BOECKER, wire-weavers and mechanical engineers, of Oelde, Germany, can look back on a corporate history of no less than one hundred and twenty-two years. Carl Haver and Eduard Boecker founded their wire-weaving works in Hohenlimburg, to the south of the present-day Ruhr industrial region, in 1887, their first products taking the form of wire cloths. The company relocated to Oelde, in Westphalia, in 1897, and began, with fifteen employees, the additional production of wire strips for bag closures for the cement industry. Initial contacts abroad had already made it possible to begin and...

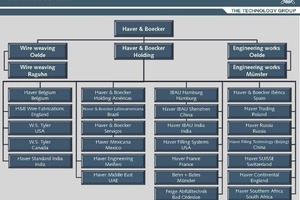

HAVER & BOECKER, wire-weavers and mechanical engineers, of Oelde, Germany, can look back on a corporate history of no less than one hundred and twenty-two years. Carl Haver and Eduard Boecker founded their wire-weaving works in Hohenlimburg, to the south of the present-day Ruhr industrial region, in 1887, their first products taking the form of wire cloths. The company relocated to Oelde, in Westphalia, in 1897, and began, with fifteen employees, the additional production of wire strips for bag closures for the cement industry. Initial contacts abroad had already made it possible to begin and expand exports as the 20th century dawned. The mechanical engineering plant was constructed adjacent to the wire-weaving works, and production of the company‘s first packing machines started, in 1925, to be followed in 1930 by the completion of the first NIAGARA® screening machine. The following thirty years saw the refinement of these machines into high-performance products, their speed and accuracy being a definitive factor in their further development. The first ROTO-PACKER® was commissioned at the Phoenix cement plant (Beckum/Germany) in 1960. Wire cloth also underwent a dramatic leap in quality around this time – this period witnessed the production of the world’s finest wire cloth, featuring 45 000 meshes/cm2 (540 mesh). The development of an extremely diverse range of screening surfaces also played a significant role. The company expanded rapidly during the 1990s, and not only with the relocation of its mineral processing activities to Münster in 1991 – a whole series of acquisitions broadened the HAVER group’s product range significantly, consolidating its international orientation and presence (see illustration). The company currently has 2,350 employees around the globe.

Not only the group’s future development, but also, most particularly, its employees’ technical and social capabilities, are of special importance to the two managing partners, Walter Haver and Dr Reinhold Festge. More than one hundred young persons are trained at Oelde every year to achieve this target. The HAVER® Academy, the company’s internal further-training platform, is available to both HAVER group employees and to customers. The courses offered by the academy, which was founded in 2007, focus on the promotion of professional, methodological, social and personal ability. Also since 2007, university-level study parallel to employment and/or training has been possible at Oelde for the employees of companies from the region, thanks to successful cooperation with other motivated enterprises, the Siemens corporation, and the South Westphalia University of Applied Sciences.

The ZKG INTERNATIONAL editorial team spoke to Dr Reinhold Festge concerning the corporate philosophy of a steadily expanding family enterprise, the survival strategies deployed by a medium-sized company in the current difficult economic climate, and concerning investments in the future, including training of the up-and-coming generation, a subject particularly dear to Dr Festge.

Dr Festge: Yes, of course – we define it under our motto, “Visions”. Our central principle is that we intend to remain a family company! The next generation is already working within our enterprise, preparing itself for future tasks. We also aim to strengthen our earning power, in order to assure our independence, and by that I mean independence from the banks, with no excessively high levels of debt, and independence from major customers, so that we do not „have all our eggs in one basket“.

Another important point is unequivocal orientation around service, i.e., we must supply the customer with the things he needs. We don’t just sell machines, we sell benefits and advantages. The precondition is that we remain the technological leaders – we must continue to offer superior quality, backed up with superior technical and process solutions.

Dr Festge: Yes, of course: in the field of mineral processing, we have developed a washer, the Hydro-Clean®, for gravel, for instance, which enables users – to name only one example – to successfully exploit contaminated deposits. The byproduct, after the washing operation, is a sludge, which we can also make salable, using a pelletizing process. In addition, the Hydro-Clean® saves 80 % of the washing water. Another example which functions in a very similar manner is the recovery of iron ore combined with pelletizing of the fine particulates produced in the process.

Dr Festge: The example I just mentioned leads directly on to a further important item: sustainable use of the available resources.

Another point of great importance to us is recognition of our social responsibility to our employees and, of course, our pensioners. We have, for example, an extremely active retired-employee community, and we also encourage employees to identify with us and to take an interest in what is happening in the individual companies.

Dr Festge: We must remain innovative! We have a number of research centers, the newest being in Freiberg – we are, in fact, the first medium-sized company to operate a university-affiliated research institute – HAVER ENGINEERING Meissen is an institute of the TU Bergakademie Freiberg Mining and Technology Academy. We also cooperate with the South Westphalia University of Applied Sciences, and, in the next few years, we will have a foundation university department in Warendorf County, which we intend to use for the study of problems and tasks in the field of mechanical engineering.

Dr Festge: We assign top priority to these activities, and we do not, at present, see any reason to reduce expenditure on them in 2009 or 2010. We have the advantage that the previous generation set up two foundations, one of which we are able to use to provide financial support for the foundation’s professorship and for the award of stipends. The last thing we intend to cut down on is training – it would, in my opinion, be a great mistake to cut back on training in times of crisis. The crisis, you see, will intensify competition among the various companies in each field, and it goes without saying that I will soon need well- trained employees. We face the problem that, in the future, we will need to recruit qualified staff from a smaller labour market. Our principle is: Anyone needing training is always encouraged.

Dr Festge: Our corporate philosophy will, of course, be refined and developed from generation to generation, it must be fine-tuned again and again, and this, naturally, can only be seen as a long-term project.

Dr Festge: We have a global presence, to assure that we are always close to our customers. We operate agencies and subsidiaries in America, China, India, Africa, Asia, Russia and Western Europe, and this is extremely important to us – we export 85 % of our production.

Dr Festge: We have an unrivalled range of products – IBAU HAMBURG, for example, is well known in the cement industry for its silo systems – and these have now also enabled this company to enter the field of power plants. Everything concerned with energy generation is currently undergoing a pronounced upturn, with extremely positive order volumes. IBAU specializes in coal-fired power generating plants. Wherever there is slag and ash, IBAU can always help with disposal. These byproducts can be used for production of certain types of cement, and IBAU provides the equipment for their recovery from the power plants, their storage, loading into ships, injection into silos, extraction and feeding into crushing mills. Our broad and diversified product range means that, from a global viewpoint, somewhere in the world, there will always be a good market for these products.

Dr Festge: Environmental impact is the paramount factor. I mean here, above all, energy-efficiency – our new ROTO-PACKER®, the HAVER ROTO CLASSIC®, consumes less energy, thanks to its enhanced-accuracy control system and its resultant higher efficiency – and its air consumption has also been cut.

Dr Festge: We are utilizing spare capacities for further development, and we have the time to do a little lateral thinking, and to advance into new fields – initially, it was not intended to develop our pelletizers so quickly, but we now have one ready to unveil at the next bauma fair in Munich.

Dr Festge: All our efforts in the next few years will continue to focus on quality and energy efficiency.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.